NT-T5 | High Speed Pick And Place Machine

Introducing the NT-T5, Nectec’s top-tier high-speed placement machine. Designed for excellence in the SMT industry, it achieves a remarkable placement speed of 84,000 CPH with dual-arm combination placement, ensuring unmatched precision and efficiency.

NXT-H | High Accuracy Mounter

NXT-H is a high-end model designed by FUJI for semiconductor and high-density placement scenarios. Its core advantages lie in full compatibility with wafers/reel materials/trays, high-precision low-impact placement, and clean room adaptability. Its modular design combines advanced vision and pressure control technology, making it suitable for complex processes such as SiP modules, power semiconductors, and micro LEDs. It also achieves efficient production management and quality traceability through intelligent software.

NXT-III | Multi-Functional Modular Placing Machine

NXT-3 is a modular placement machine designed by FUJI for multi-variety and high-mix production scenarios. Its core advantages lie in flexible modular architecture, high-precision low-impact placement and intelligent production management. It supports the full range of processing from ultra-small chips to large special-shaped components, combined with advanced visual inspection and error-proofing technology, and is suitable for automotive electronics, mobile devices, semiconductor packaging and other fields with extremely high requirements for precision and efficiency. Through deep integration of software and hardware, it achieves fast changeover, efficient production and full-process quality traceability, and is one of the core equipment of intelligent factories.

NXT-R | High-End Modular Placement Machine

NXT-R takes "zero defects, zero labor, and zero downtime" as its core, and realizes efficient production and high-quality placement of multiple varieties through modular design, intelligent feeding, high-precision placement head and full-process sensor detection. Its core advantages are: Unmanned material management: The intelligent loading vehicle completely liberates the operator and reduces human errors; Full-scenario adaptation: From small chips to large special-shaped components, it is compatible with flexible circuit boards and ceramic substrates; Data-driven quality: LCR detection, 3D coplanarity scanning and other technologies intercept early defects, with a yield rate of more than 99.9%.

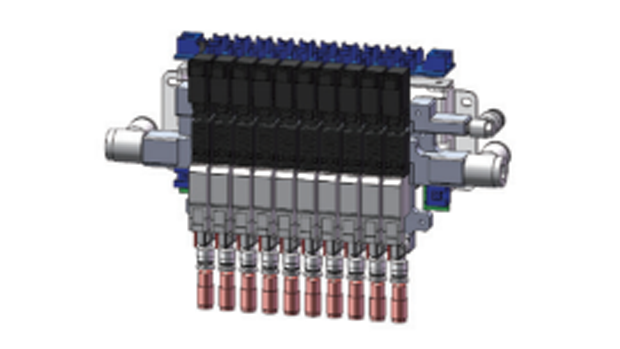

RS-1R | Smart Fast Modular Mounter

The consistent further development of the tried-and-tested technologies from the RS-1R opens up new, outstanding possibilities: Even faster assembly of smallest chips (0201 metric) up to large components of 50 x 150 mm or 74 mm edge length for square components. The base frame of the RS-1R has been completely redesigned for this purpose. The unique Takumi head covers even more different component heights and thus achieves a decisive speed advantage. The 360° visual component recognition allows the secure detection of user-specific polarity marks. Thanks to the RFID integration in the nozzles, these can be traced back completely together with the components and boards. The machine combines the features of a chip shooter with a mounter for large components. The purchase of each special machine type for it eliminates as well as a change of the placement head.

RS-1XL | Fast Smart Modular Mounter

With maximum speed up to 42,000CPH (Optimum) and 29,000CPH (IPC9850), the RS-1XL is designed for maximum throughput. The RS-1XL supports components from 0201 metric (008004") up to 74mm square and 50mm x 150mm rectangular parts for maximum flexibility.

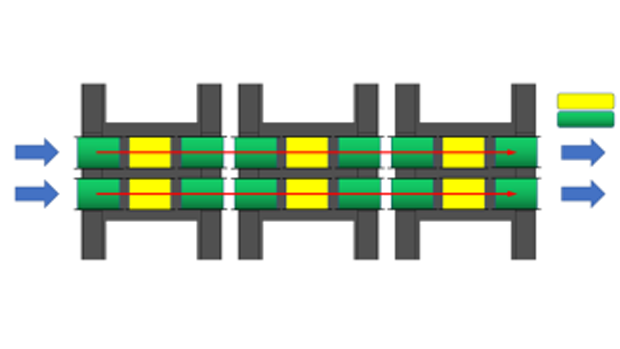

RX-6B | High-Speed Compact Modular Mounter

The compact RX-6R/RX-6B offers high productivity, flexibility and quality – in a compact footprint. This is applicable to dual-lane production.Compact footprint : the width is just 1.25m.Equipped with standard Placement Monitor check function.Replaceable head allow you to configure a production line best suited to the current repirments.High-speed component placement using high-speed non-stop vision recognition.Wide range of components and boards: tall components, large components and large boards.Brand new Matrix Tray Sever TR8S improves the component capability and productivity.

RX-8 | High -Speed Compact Modular Mounter

JUKI RX-8 achieves ultra-high speed (100,000 CPH) and high precision (±40μm) micro-component placement through P20 placement head, high-precision vision system and intelligent feeding management, which is especially suitable for high-density placement scenarios such as consumer electronics and LED lighting. Its compact design and JaNets system support efficient production line integration and process optimization, and is a benchmark for SMT equipment that takes into account speed, precision and flexibility.

S10 | 3D Hybrid Universal Module Placement Machine

The S10 model has 3D placement capabilities. It can realize 3D placement with interactive solder paste dispensing and component placement through the newly developed interchangeable dispensing head; it can be expanded to 3D MID placement, and can operate on concave and convex, inclined and curved surfaces to meet the needs of automotive, medical, communication equipment and other fields. It can handle large and long substrates with a maximum size of L1,330 x W510mm (when the buffer function is not used), and can be accurately positioned by laser sensors to adapt to PCBs of different shapes and sizes. It also has a variety of component processing: it can handle components from 0201mm to 120 x 90mm, including BGA, CSP, connectors, etc.; the maximum component height is 30mm (including substrate thickness); the maximum feeder capacity is 90 types (converted to 8mm tape), and supports multiple feeding methods. Its placement speed and accuracy have reached 0.08 seconds/CHIP (45,000CPH) under the best conditions for 12-axis 20-head unit, CHIP placement accuracy ±0.040mm, IC placement accuracy ±0.025mm, and placement angle ±180 degrees. Its equipment size is L1,250 x D1,750 x H1,420mm and weighs about 1,200kg. It also has negative pressure and image dual component return detection function and color reference mark recognition camera with new lighting unit to improve recognition accuracy; and supports multi-language operation interface. Its feeder compatibility is strong, and new and existing material change trolleys can be mixed and used.

S20 | 3D Hybrid Universal Placement Machine

The Yamaha S20 fulfills the need for higher throughput in the flexible assembly and LED lighting sectors. The new high capacity head system addresses the need for faster cycle times and provides ultra-large PCB handling capabilities with higher placement rates. The highly flexible S20 is available with the new head system incorporating 12 spindles with a wide component handling range. The S20 utilises the same fast change feeder bank and tray handler capabilities as the popular M20 and has a feeder capacity of up to 180 feeder positions. The optional camera will allow placement of parts down to 0.2 x 0.1 mm fulfilling the current demands on reduced component and ball sizes.

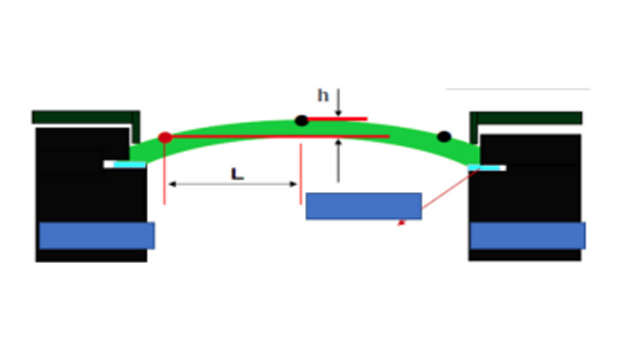

SIPLACE CA2 | Hybrid Mounter

As a hybrid combination of an SMT placement machine and a die bonder, the new SIPLACE CA2 can process both SMDs supplied from changeover tables and feeders as well as dies taken directly from the sawn wafer in a single work step. By integrating the complex die bonding process into the SMT line, it eliminates the need for special machines in production. With reduced personnel deployment, high connectivity, and integrative data utilization, the SIPLACE CA2 is therefore the perfect match for the Intelligent Factory.

SIPLACE X S | High-speed placement

The SIPLACE X S is benchmark in high-volume production. Absolute precision and maximum performance have made the SIPLACE X S the placement platform of choice for demanding high-volume production applications such as network infrastructure (5G), large boards for server and industrial segments. Wherever top speed, lowest dpm rates, non-stop setup changeovers, fast new product introductions and the high-speed placement of the latest generations of super-small components (0201 metric) are needed.