SIPLACE-SX | Cantilever modular placement machine

SIPLACE SX is the first placement solution that is fully scalable with demand thanks to its unique interchangeable gantries. A great way to add capacity when needed or reduce capacity when things slow down. We call it ASMPT Capacity-on-Demand.The SIPLACE SX-Series puts scalability and flexibility at the top of the list. Users are able to introduce new products quickly, change setups without stopping the line and produce any batch size with high utilization and efficiency.Whether in automotive, automation, medical, telecommunication or IT infrastructure – the ASMPT SX-Series meets all requirements in terms of quality, process reliability and speed.

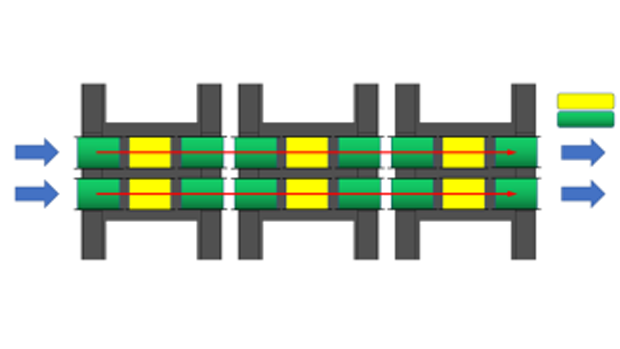

SIPLSCE TX | High Speed Component Placement Machine

The compact SIPLACE TX modules make it very easy to scale your lines up or down. Optimizing each line is less of an undertaking, because getting the perfect balance between requirements and the number of machines is easier than ever.No matter with how many modules you start your line – you can increase its performance in steps of just 1 meter (3.3 feet) or 78,000 cph by adding more SIPLACE TX modules.Maximum accuracy – guaranteed Extremely fast and accurate: With up to 22 µm at 3 sigma, the new SIPLACE TX modules operate with top accuracy.Technological breakthrough: The SIPLACE TX is capable of placing super-fine-pitch 0201 (metric) components at highest speed.This unique combination of accuracy and record-breaking speed makes the SIPLACE TX the clear winner in the race for high-volume 0201 placements.But that‘s not all. No matter how many components you place, our improved control and head technologies protect the machine’s performance and accuracy for years to come.Extremely powerful and designed for the high-volume placement of future component generations, the SIPLACE TX modules deliver the level of investment protection electronics manufacturer want and need for their Smart SMT Factory.

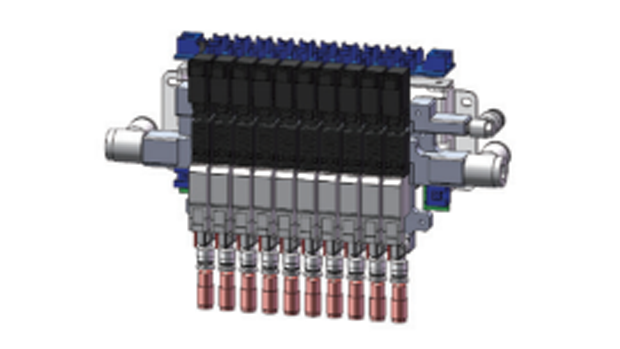

SM471plus | Fast Chip Shooter

Introducing the DECAN-S2, Hanwha’s Fast Chip Shooter.It has 2 Gantries and 10 Spindles to achieve speed of 78000 CPH.The accuracy of the machine is about ±40 μm [±3σ (Chip))] or ±50 μm [±3σ (QFP)].And its dimension is 1,650*1,690*2,045(L*D*H,Unit: mm).

SM481plus | Flexible Placer

Introducing the SM481plus, Hanwha’s Flexible Placer.It has 1 Gantry and 10 Spindles to achieve speed of 40000 CPH.The accuracy of the machine is about ±40 μm [±3σ (Chip)] or ±30 μm [±3σ(QFP)].And its dimension is 1,650*1,680*2,090(L*D*H,Unit: mm).

SM482plus | Multi-Functional Placer

Introducing the SM482plus, Hanwha’s Multi-Functional Placer.It has 1 Gantry and 6 Spindles to achieve speed of 30000 CPH.The accuracy of the machine is about ±40 μm [±3σ (Chip)] or ±30 μm [±3σ(QFP)].And its dimension is 1,650*1,680*2,090(L*D*H,Unit: mm).

SM485 | Wide Ranged Component Placer

Introducing the HM520, Hanwha’s Wide Ranged Component Placer.It has 1 Gantry and 4+1 Spindles to achieve speed of 22000 CPH.The accuracy of the machine is about ±40 μm [±3σ (Chip))] or ±30 μm [±3σ (QFP)].And its dimension is 1,650*1,680*1,530(L*D*H,Unit: mm).

YRM10 | Compact High-Speed Modular

Yamaha's YRM10 model is equipped with the advanced technology of the YRM series high-end system. It is a small multi-functional high-speed placement machine with excellent cost performance and high placement capacity, realizing value-added production of economical products, and achieving zero-defect production with high placement accuracy and rich functions. It brings excellent ease of use because of the simple single-head operation.

YRM20 | Premium High Efficiency Modular Placement Machine

The 1 head solution has reached an ultimate stage. YRM20 is an all-around surface mounter delivering both overwhelming productivity and flexibility! Fusion with Σ technology achieves overwhelming productivity Broad-ranging production capability thanks to the 1 head solution Standard features that maintain component mounting quality at a peak level. Ensures high-efficiency production with a full range of functions.

YRM20DL | Super High Efficiency Dual Lane Modular Placement Machine

The YRM20DL is a dual track surface mount machine with excellent productivity, flexibility and PCB placement capabilities. It provides a wide range of production capabilities as a single head solution, suitable for multi-variety and multi-batch production. It can achieve high-precision placement and stable production of micro components.

YSM10 | Compact High-Speed Modular

YSM10 is the entry-level placement machine of the YSM series, achieving the fastest speed and versatility in its class. As a basic model, YSM10 can flexibly cope with various production configurations and ensure stable production functions. It has a single-beam single-head placement machine, and the chip placement performance under optimal conditions reaches 46000CPH.It offers high - speed and precise placement, handling a wide range of component sizes from tiny 01005s to large odd - shaped parts. With advanced vision and alignment systems, a user - friendly software interface, and excellent mechanical reliability, it enables seamless integration into production lines for efficient and high - quality electronic assembly.

YSM20R | Multi-Function and High-Efficiency Modular Placement Machine

The YSM20R is a versatile surface mount machine with the fastest placement speed in its class, taking the innovation of single-head placement solutions to a new level. Its placement speed is 5% faster than the YSM20. The YSM20R is equipped with a new wide-angle scanning camera, which is more adaptable to components. Optional functions can increase the production line operation rate without stopping the machine.

YSM20WR | High-Efficiency Modular Placement Machine

Yamaha YSM20WR SMT machine, this versatile SMT machine has the fastest speed in its class, taking the innovation of single-head SMT solutions to a whole new level. The fastest SMT speed in its class, YSM20WR is 5% faster than YSM20. It is equipped with a new wide-angle scanning camera and has stronger component adaptability. Optional functions can increase the production line operation rate without stopping the machine.