NX-B | Battery X-ray Inspection System

The NX-B equipment, designed for precision and reliability, specializes in battery inspection. It detects electrode lug morphology via advanced X-ray imaging, featuring a 90kV/200uA sealed tube and 85um pixel FPD for 5um resolution. With 20fps imaging and 16-bit AD conversion, it ensures accurate defect identification in power batteries.

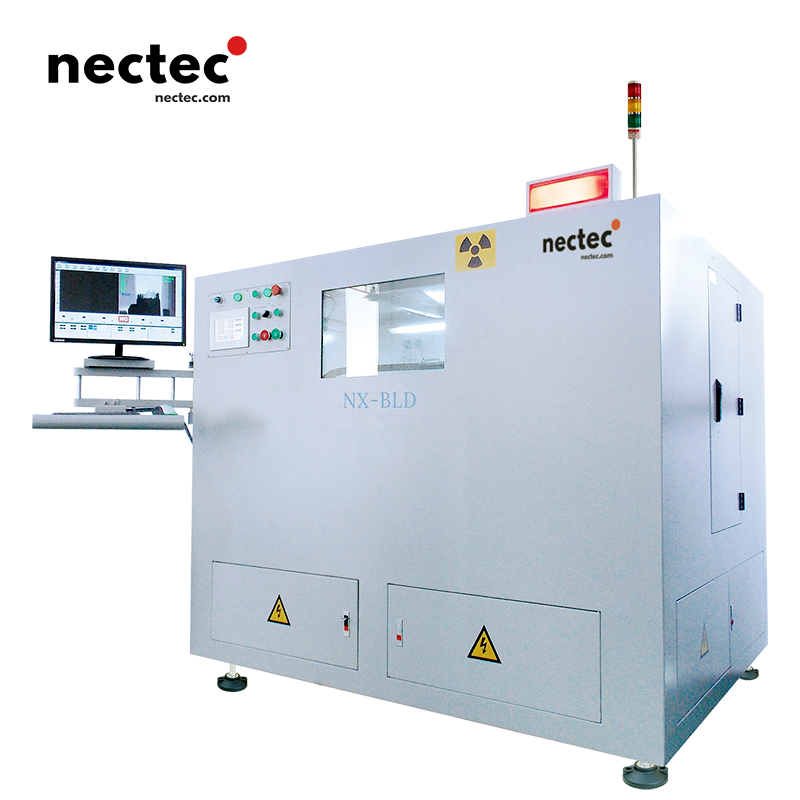

NX-BLD | Laminated Battery X-ray Inspection System

Discover the unparalleled fully automatic X-ray inspection technology for power stacked cells with our advanced equipment NX-BLD. Engineered to provide comprehensive detection, our solutions identify defects in battery electrode sheets and stacking deviations, ensuring high efficiency and scalability for batch inspections. With a modular design and seamless production line integration, our system offers automatic loading, unloading, and sorting of products. Equipped with self-developed lithium battery testing software, our technology ensures top-tier quality control and operational excellence.

NX-BLI | Battery X-ray Inspection System

The X-Ray machine NX-BLI detects internal battery structures and electrode coatings, ensuring comprehensive inspection of negative electrodes and shell walls. Suitable for 18~26 series batteries, it features a high-speed transmission mechanism for efficient operation. The modular design allows for expansion, with automatic loading/unloading and seamless production line integration. Advanced features include automatic determination, data storage, and defect isolation, achieving full automation with a capacity of 60-120 PPM.

NX-C1 | SMT X-ray Reel Counter

The NX-C1 offline X-Ray counting system is engineered to efficiently handle all types of resistors, capacitors, and IC materials. It delivers fast, precise counting (up to 99.9% accuracy) and streamlined inventory management for 7-17 inch Tray/Jedec Tray/C moisture sensitive bags, etc. Equipped with 80kV/150uA sealed tube and 3072*3072 pixel Gamma FPD, it enables intelligent anti-interference counting of 1-4 disks within 8 seconds, supporting ERP/MES/WMS integration.

NX-C2 | Inline Automatic X-Ray Counter

The NX-C2 is a fully automatic X - Ray point system. It is applicable to all resistive, capacitive, and iC materials, enabling rapid counting and inventory of various trays. It features fast and high - precision chip counting to reduce labor costs, non - contact counting to avoid chip damage or loss, a feeding method with 1 - 4 stations for selection, a six - axis robot arm with machine vision for automatic labeling, material grabbing (more flexible, efficient, and with high recognition accuracy, capable of covering original labels as small as 0.01mm), the ability to connect to AGV loading for unmanned loading, support for connection with ERP, MES, and WMS systems, and an advantage in space occupation as it has no NG warehouse.

NX-CT160 | X-ray Inspection System

The NX-CT160 is a cutting-edge 3D X-ray inspection system specifically designed for advanced wafer technology, surface-mount technology (SMT), packaging inspection, and semiconductor applications in laboratory settings. It excels at detecting issues such as solder and tin voids, as well as bonding wire defects commonly found in SMT and semiconductor manufacturing. Additionally, the system effectively identifies packaging defects, including offsets, wire cross short circuits, flip-chip solder ball problems, wire breakage, and detachment.

NX-E1 | Electronics X-ray Inspection System

The NX-E1 machine is designed for detecting welding defects in electronic components. It specializes in inspecting PCB, SMT assembly, IC packaging, BGA, CSP, semiconductors, etc. Equipped with a sealed X - ray tube (90kV, 200uA) and 85um pixel FPD, it achieves 5um detail resolution for precise defect identification.

NX-E1L | Electronics X-ray Inspection System

The NX-E1L machine serves semiconductor, SMT, DIP, electronic components, IC, BGA, CSP, and flip chip X - ray detection. It has a high - resolution FPD for high - quality images to detect minimum 2um defects, uses CNC programming for automatic positioning with 45° tilt detection, offers real - time navigation imaging and HDR enhancement, and provides measurement tools like size, area, angle, and curvature.

NX-E3 | Electronics X-ray Inspection

The X - Ray machine NX-E3 features a strong - penetrating ray source and HD FPD for universal inspection. With a 70° - tilting detector, 360° - rotating stage, and six - axis linkage for all - round control/detection, it has high - definition navigation images for fast product positioning, plus HDR enhancement and measurement tools like size/area/angular curvature.

NX-E3L | Electronics X-ray Inspection System

The NX-E3L machine serves semiconductor, SMT, DIP, electronic components, IC, BGA, CSP, and flip chip X - ray detection. It has a high - resolution FPD for high - quality images to detect minimum 2um defects, uses CNC programming for automatic positioning with 45° tilt detection, offers real - time navigation imaging and HDR enhancement, and provides measurement tools like size, area, angle, and curvature.

NX-E6LP | Automatic Inline X-ray Inspection System

The X-Ray machine NX-E6LP is used for detecting BGA and chip compon-ents; Nickel plate detection of metal plate andFPC welding parts, calculation of bubble perc.entage, size, area measurement, analysis ofinternal defects such as low tin and virtual soldering in products.The advanced inspection equipment is specifically designed for detecting BGA and chip components, nickel plate detection on metal plates, and FPC welding parts. It efficiently calculates bubble percentages, measures size and area, and analyzes internal defects such as low tin and virtual soldering in products.

NX-EF | Electronics X-ray Inspection System

The NX-EF machine is applied to detect welding defects in electronic components. It is capable of inspecting PCB, SMT assembly, IC packaging, BGA (Ball Grid Array), CSP (Chip Scale Package), semiconductor and other components. With its advanced technology, it can accurately identify various welding issues, ensuring the quality and reliability of electronic products.