Lowering Gate SMT Conveyor | PCB Handing Conveyor

The Lowering Gate SMT Conveyor is designed to enhance accessibility and streamline the transport of printed circuit boards (PCBs) within manufacturing environments. This conveyor system allows for easy access while ensuring efficient movement of components through various production stages.

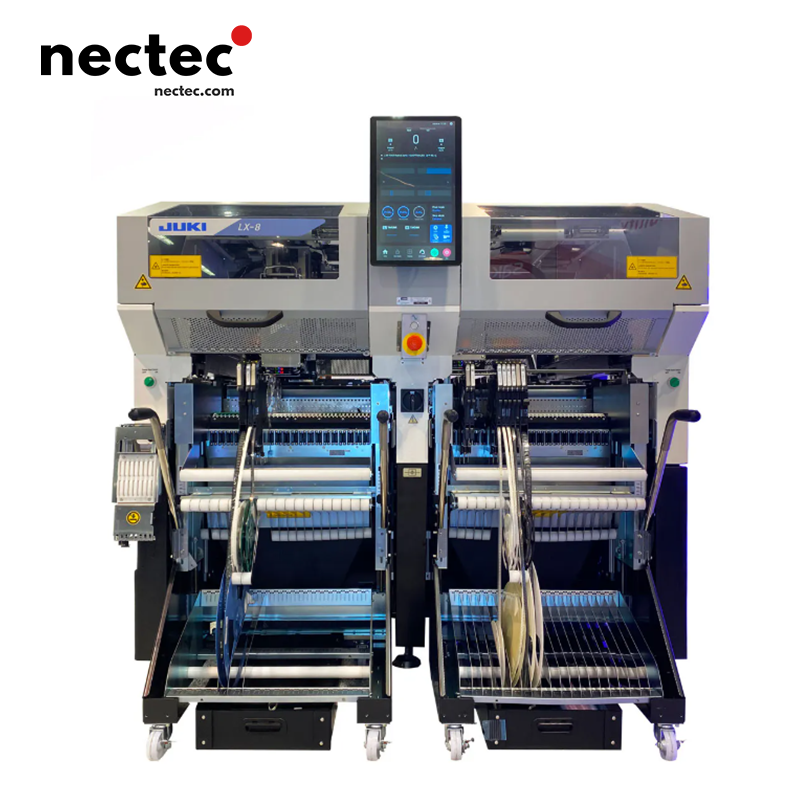

LX-8 | High-speed Flexible Mounter

JUKI's LX-8 is the ultimate solution for any production line. With its cutting-edge technology and versatility, it features double Takumi heads for exceptional performance and precision. Despite reaching top speeds of up to 94,000 CPH, the LX-8 ensures an exceptional accuracy rate of ±30 μm (Cpk ≥1), delivering precision and quality with every placement.

Multifunctional Vertical Type Buffer | PCB Handing Buffer

The Multifunctional Vertical Type Buffer is designed to optimize workflow in SMT production lines by providing a compact and efficient storage solution for PCBs. Its vertical design maximizes space utilization while ensuring quick access to materials.

NG Buffer | PCB Handing Buffer

The NG Buffer is designed to effectively manage and store non-conforming (NG) PCBs in SMT production lines. This system ensures that defective boards are handled efficiently, minimizing disruptions to the production process.

NG/OK Auto Unloader | PCB Handing Loader & Unloader

The NGOK Auto Unloader is designed to efficiently remove PCBs from SMT production lines, enhancing workflow and reducing manual handling. This automated system ensures quick and reliable unloading of assembled boards, improving overall production efficiency.

NI-H20 | Super Series Radial Component Insert Machine

The NI-H20 Super Series Radial Component Insert Machine, belonging to the M, H, and K series of component insertion machines, is one of the core pieces of equipment in the through-hole mounting process of the electronics manufacturing industry. Its core purpose is to solve the efficiency balance problem between upstream and downstream processes on the production line, adapting to surface mount technology (SMT) production lines and various electronic component insertion needs. It is particularly suitable for mass production scenarios with high requirements for insertion speed, accuracy, and stability, such as PCB insertion production for power supplies, small household appliances, and automotive electronics.

NI-H30 | Super Series Axial Component Insert Machine

NI-H30 超级系列轴向元件插入机(HA30S 系列卧式元件插入机)是复合式垂直/水平通孔元件插入系统解决方案的核心产品。它专注于满足电子制造领域个性化、多样化的批量生产需求,并兼容表面贴装生产线 (SMT) 以及选择性焊接、通孔回流焊等特殊工艺。该设备可实现无缝集成,降低人力、缺陷率等不可控因素,从而提高生产效率。

NI-K6S | Super Series Auto High Speed Radial Insert Machine

The NI-K6S is a Super Series Auto High Speed Radial Insert Machine, primarily positioned as a dedicated device for high-efficiency mass production in the electronics manufacturing industry. Focusing on the demands of ultra-high speed, high precision, and high integration, it is suitable for large-scale mass production scenarios such as power supplies, automotive electronics, communication equipment, and industrial control boards. It can seamlessly integrate with SMT production lines, significantly improving insertion efficiency and process stability.

NI-M30 | Super Series Axial Component Insert Machine

The NI-M30 Super Series Axial Component Insert Machine (MA30S series horizontal component insertion machine), belonging to the M, H, and K series component insertion machines, is an important component of a composite vertical and horizontal through-hole component insertion system solution. Its core positioning is to meet the systematic and standardized mass production needs in the electronics manufacturing industry. It is compatible with surface mount technology (SMT) production lines and special processes such as selective soldering and through-hole reflow, enabling seamless integration, reducing uncontrollable process factors such as manpower and defect rates, and improving production stability and efficiency.

NI-R20 | Super Series Radial Component Insert Machine

The NI-R20 Super Series Radial Component Insert Machine, belonging to the M, H, and K series of component insertion machines, is a key piece of equipment in the through-hole mounting process of electronic manufacturing. Its core positioning is to adapt to diverse, high-precision mass production needs, seamlessly connecting to surface mount technology (SMT) production lines and special processes. It is widely used in PCB insertion production for power supplies, small appliances, automotive electronics, industrial control boards, and other products, and is particularly adept at solving the balance between flexibility and stability in complex processes.

NI-R20E | Super Series Integrated Radial Insert Machine

The NI-R20E is a Series Integrated Radial Insert Machine, primarily designed for small-space, low-partition, and small-sized PCB manufacturing scenarios. It is tailored for customers with limited part numbers, limited workshop space, and small PCB sizes, effectively solving space constraints while ensuring insertion efficiency and accuracy. It is suitable for small- to medium-volume electronic manufacturing scenarios, such as PCB assembly for small power supplies, mini home appliances, and micro control boards.

NPM D3A | High Volume Placer

The compact dual-beam NPM-D3A offers a reinforced frame, advanced head, and award-winning Multi Recognition Camera improve placement accuracy down to 30um, and capable achieving a maximum CPH of 92,000. The NPM-D3 is an industry standard building block in high-speed, high volume applications ranging from automotive to industrial to medical. In fact, the vast majority of automotive EMS providers choose Panasonic Connect solutions.