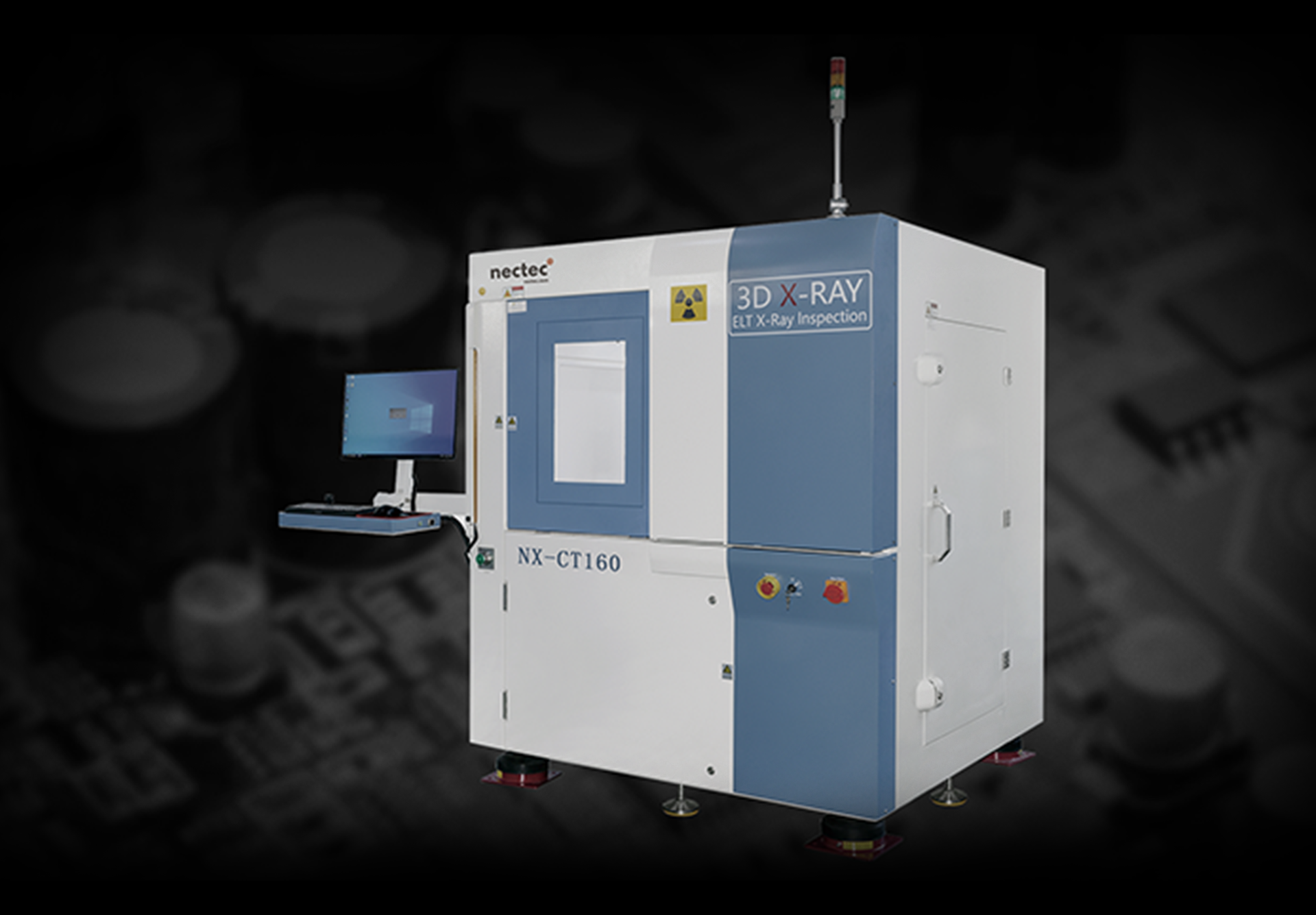

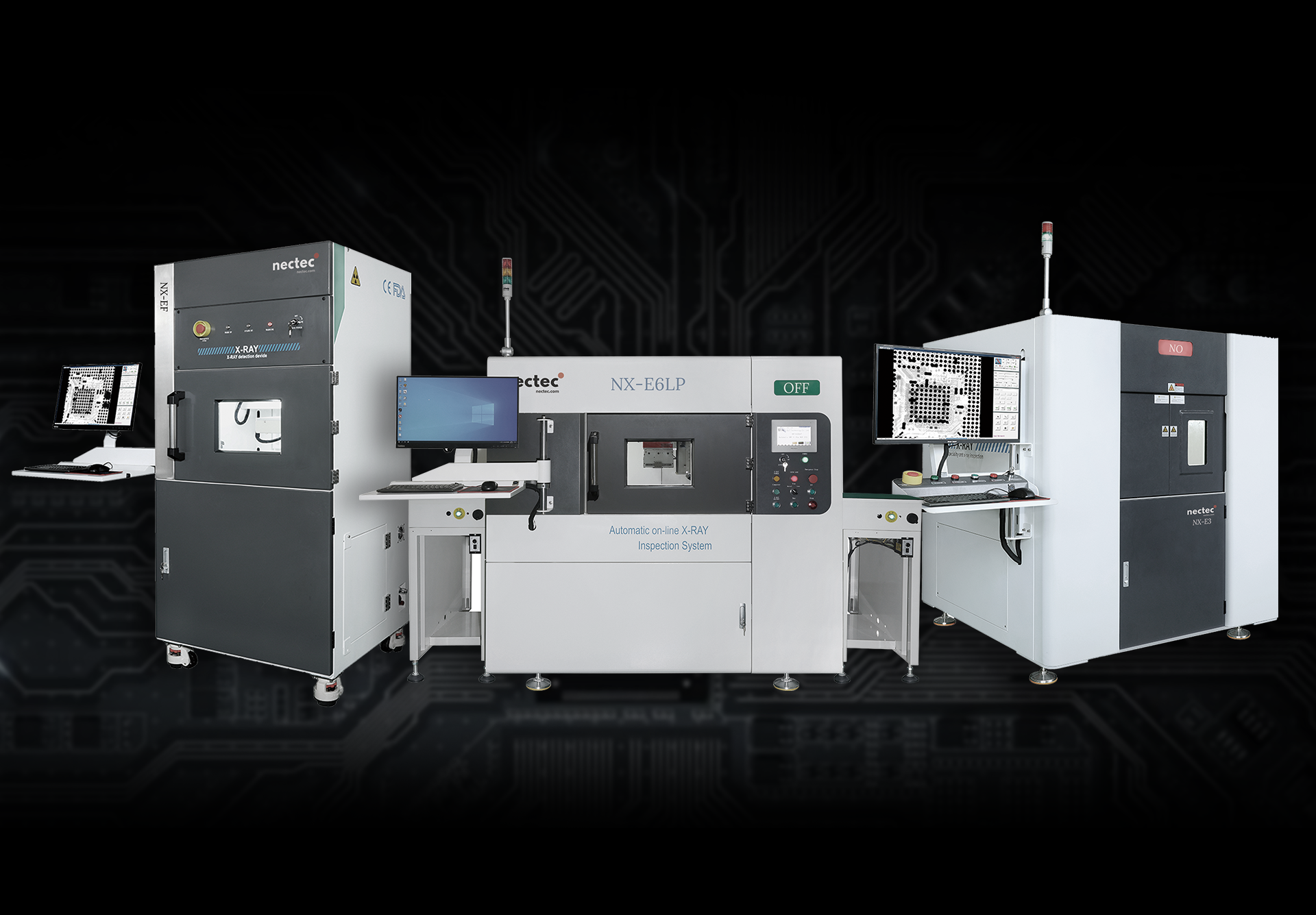

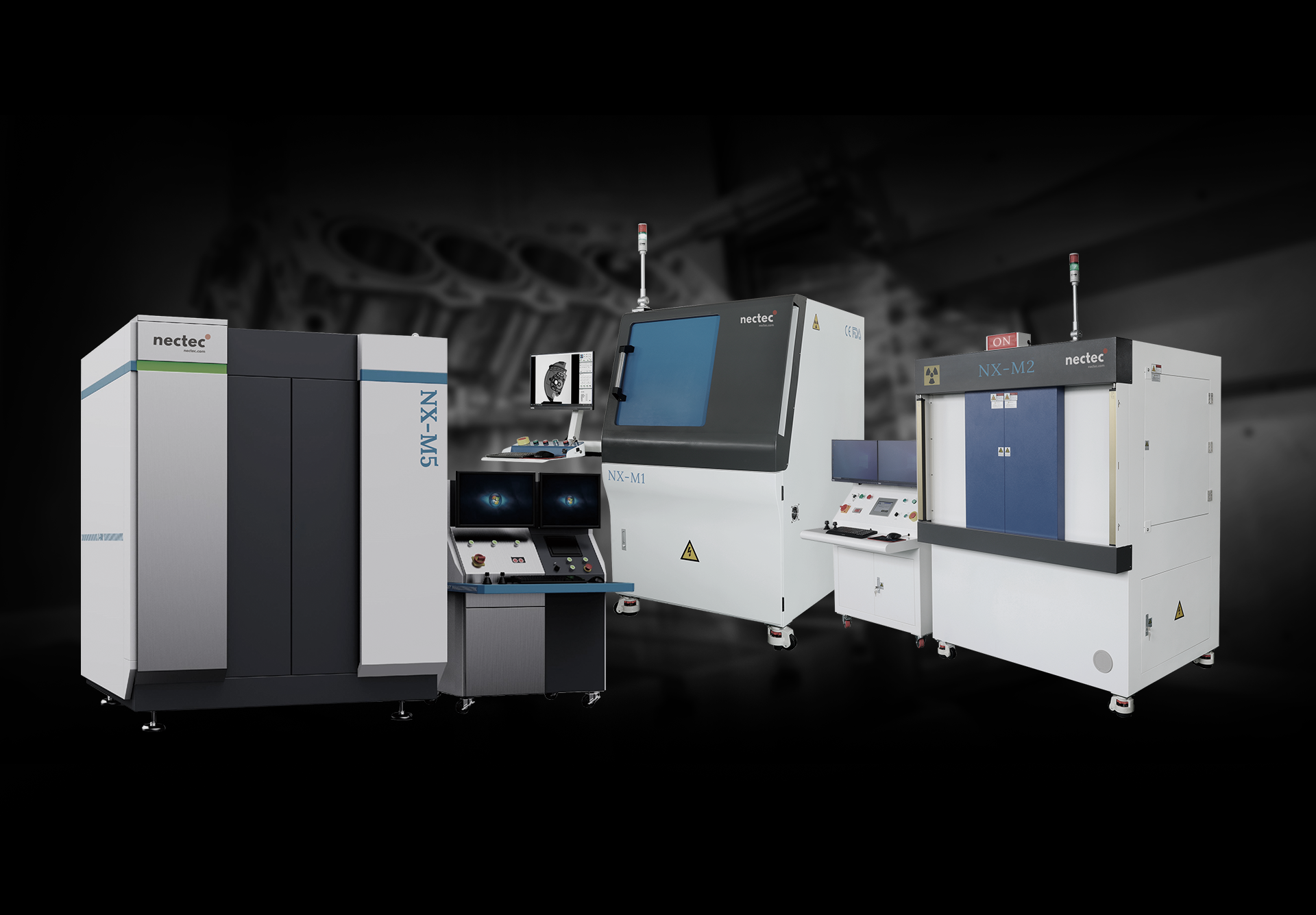

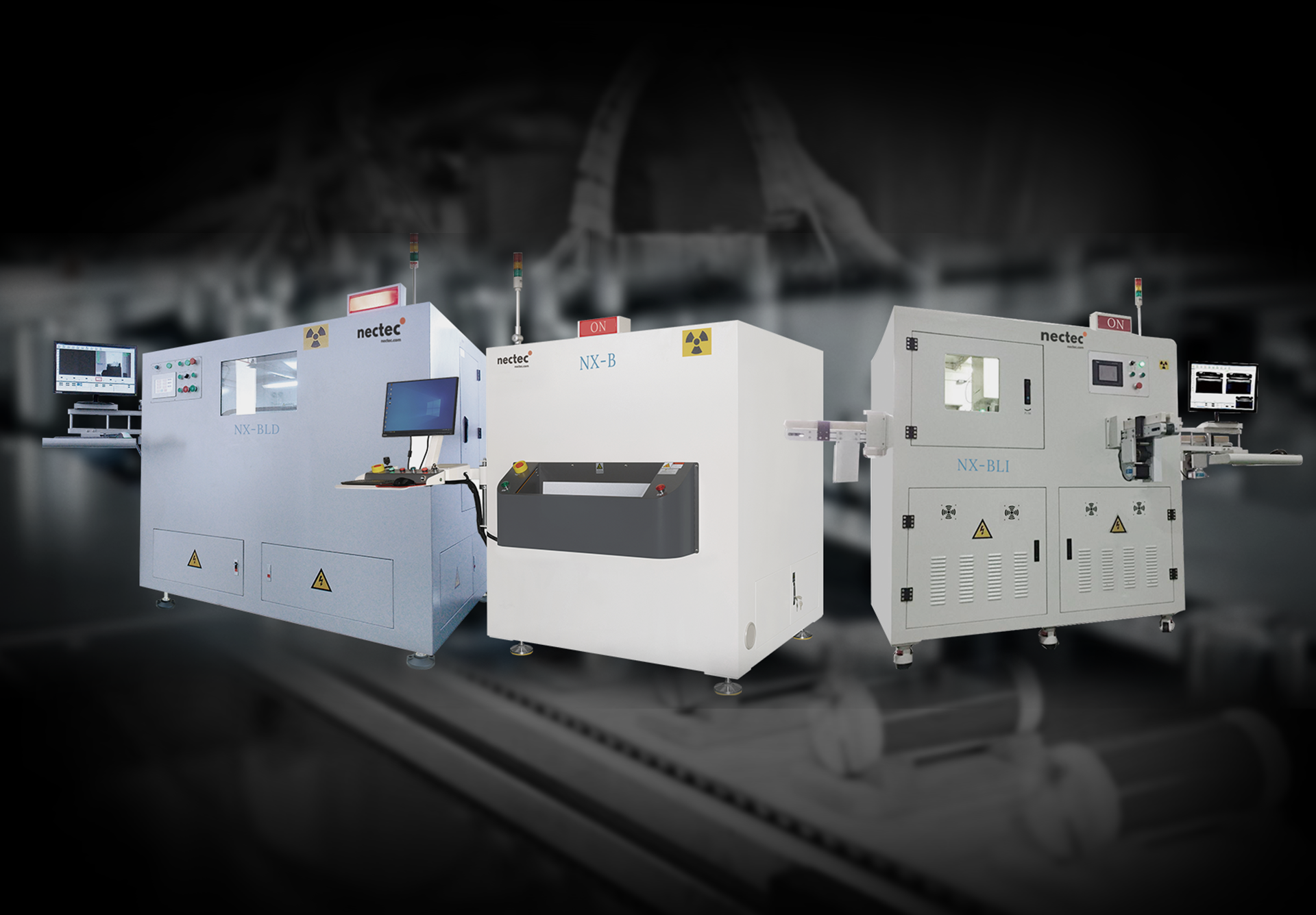

NECTEC X-ray Product Line

x-ray

Explore Our Product Line

Enhanced X-Ray Inspection and Intelligent Counting Solutions

Our advantages

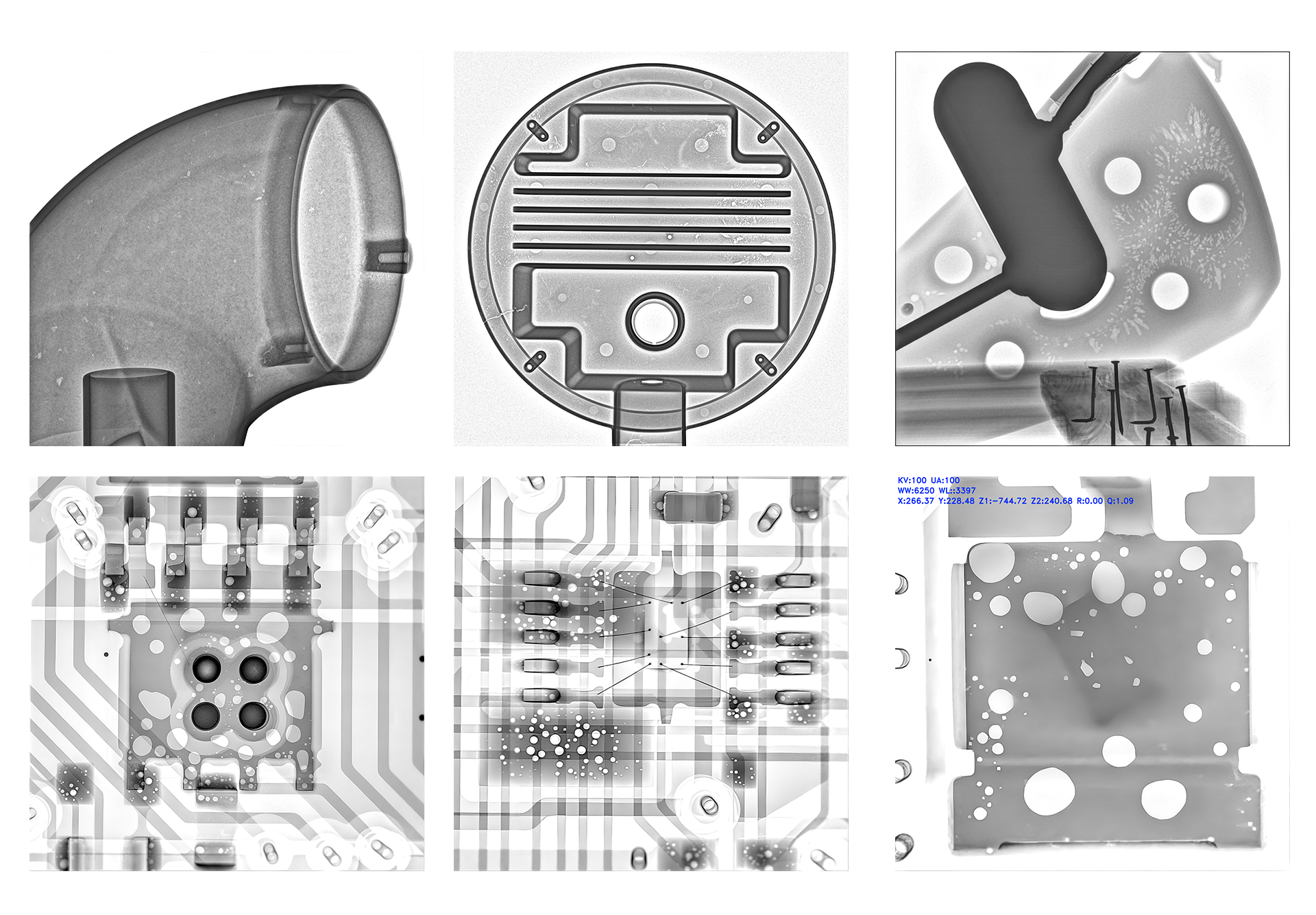

HDR Imaging

Real-time dynamic imaging in Nectec X-ray inspection machines features HDR image enhancement for superior quality and detail. By combining multiple exposures, HDR captures a wider brightness range, enhancing contrast and material differentiation. This improves flaw detection, reduces noise, and aids in identifying materials or foreign objects. Integrating HDR ensures accurate measurements and advanced analysis, making our X-ray inspection machines more reliable and effective for quality control across industries.

Our advantages

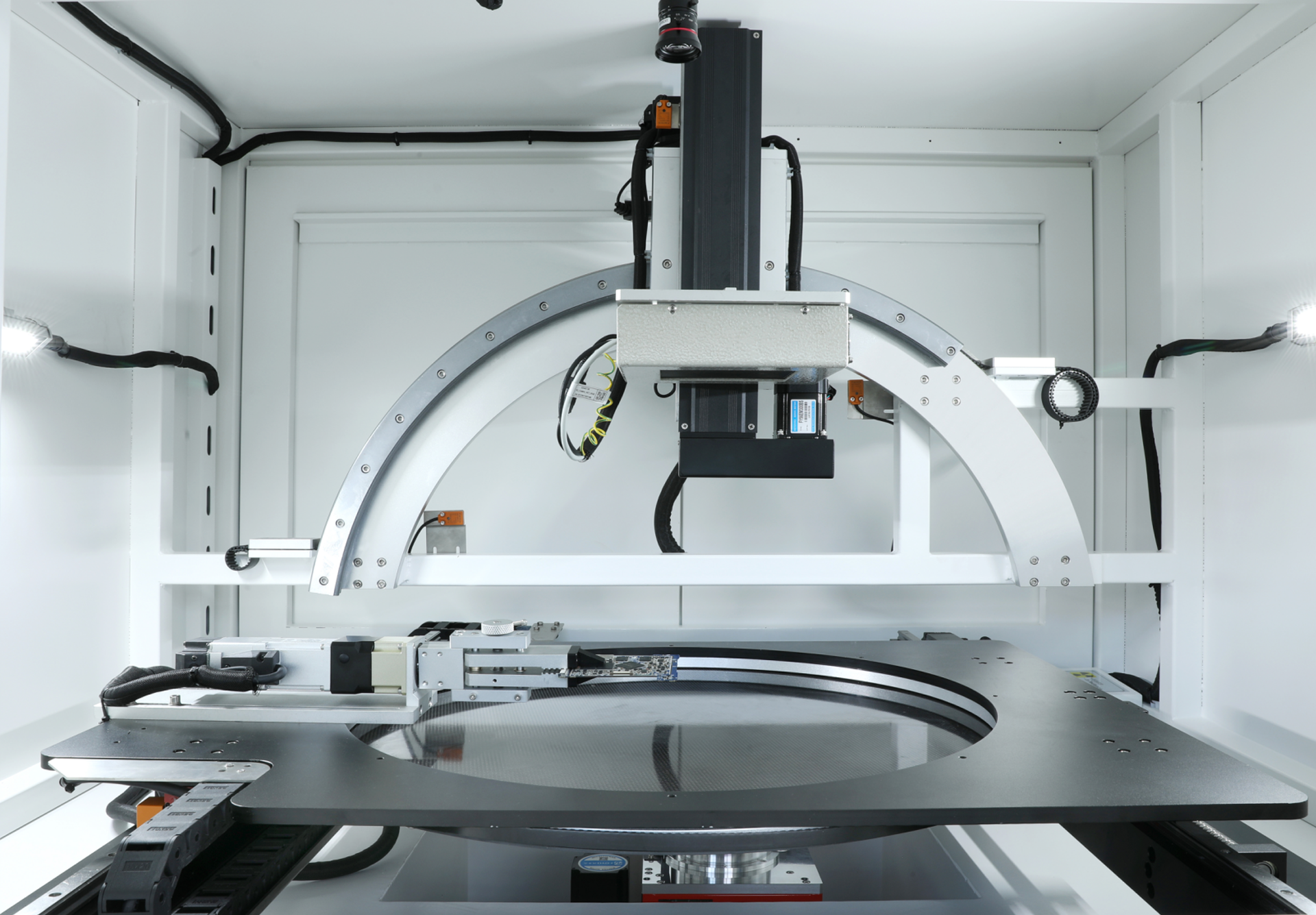

HDR Imaging

The Nectec X-ray inspection machine, equipped with multi-axis capabilities and tilt, provides comprehensive imaging from various angles for detailed flaw detection. It adapts to diverse shapes and sizes, increasing versatility. Multi-axis systems reduce inspection time by capturing multiple views in one setup and enable accurate 3D reconstruction for enhanced quality control analysis.

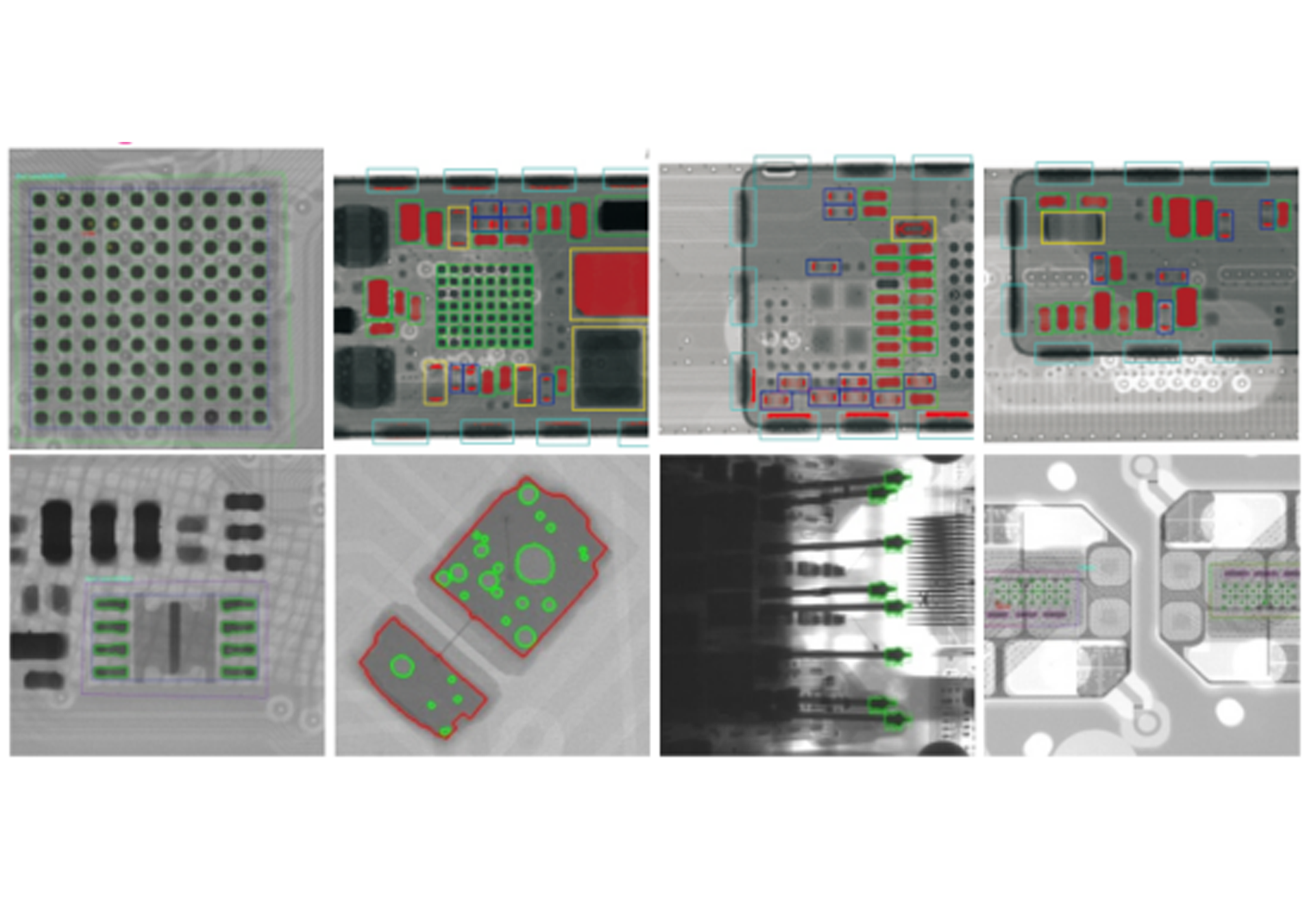

Our advantages

Automated inspection

Automated inspection in Nectec X-ray inspection machines streamlines quality control by using advanced algorithms to analyze images without human intervention. It ensures faster, consistent defect detection while reducing human error. Integrated with data management tools, it enables real-time monitoring, reporting, and enhanced traceability. Overall, our X-ray inspection machine improves efficiency and effectiveness across industries.

Our advantages

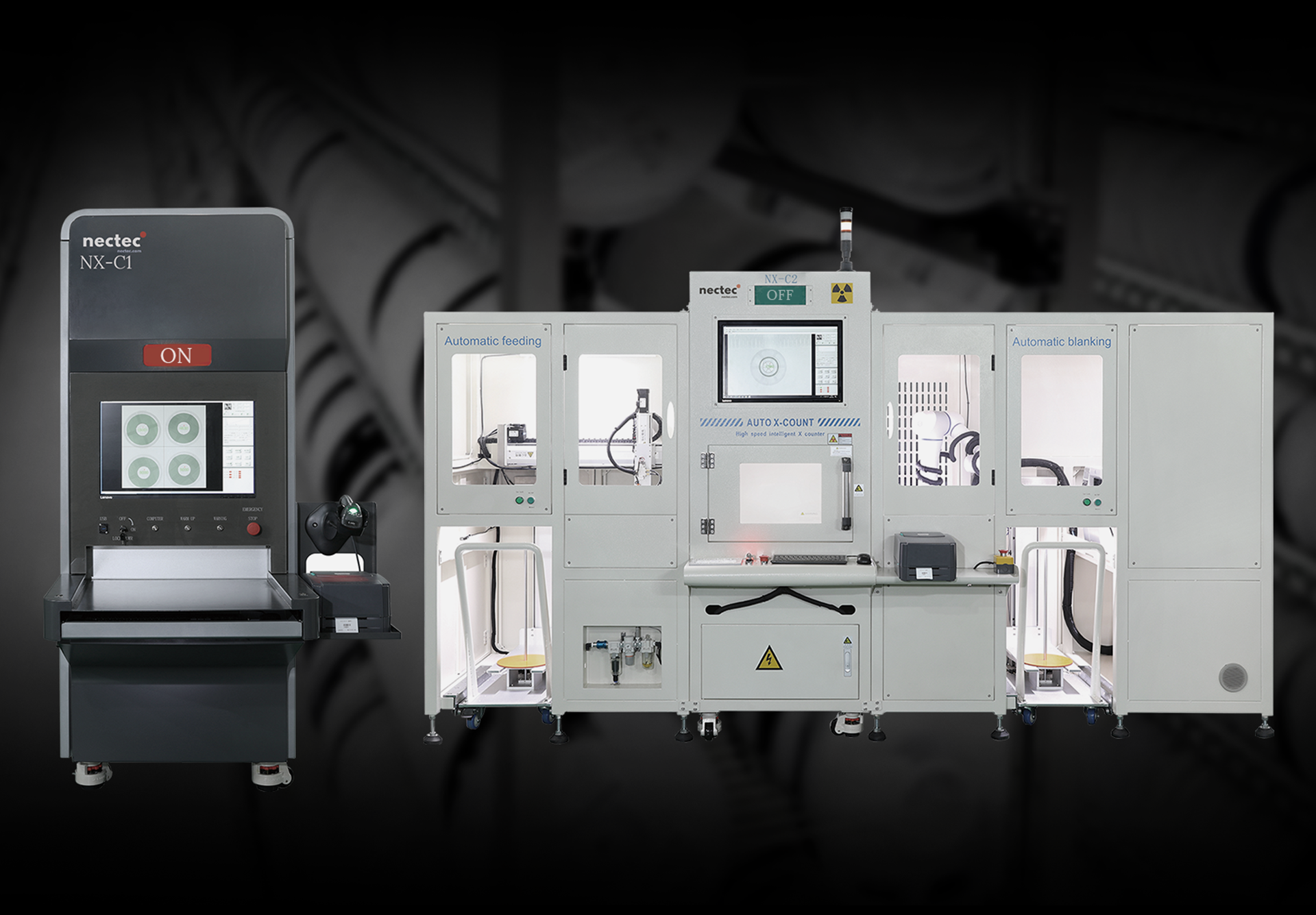

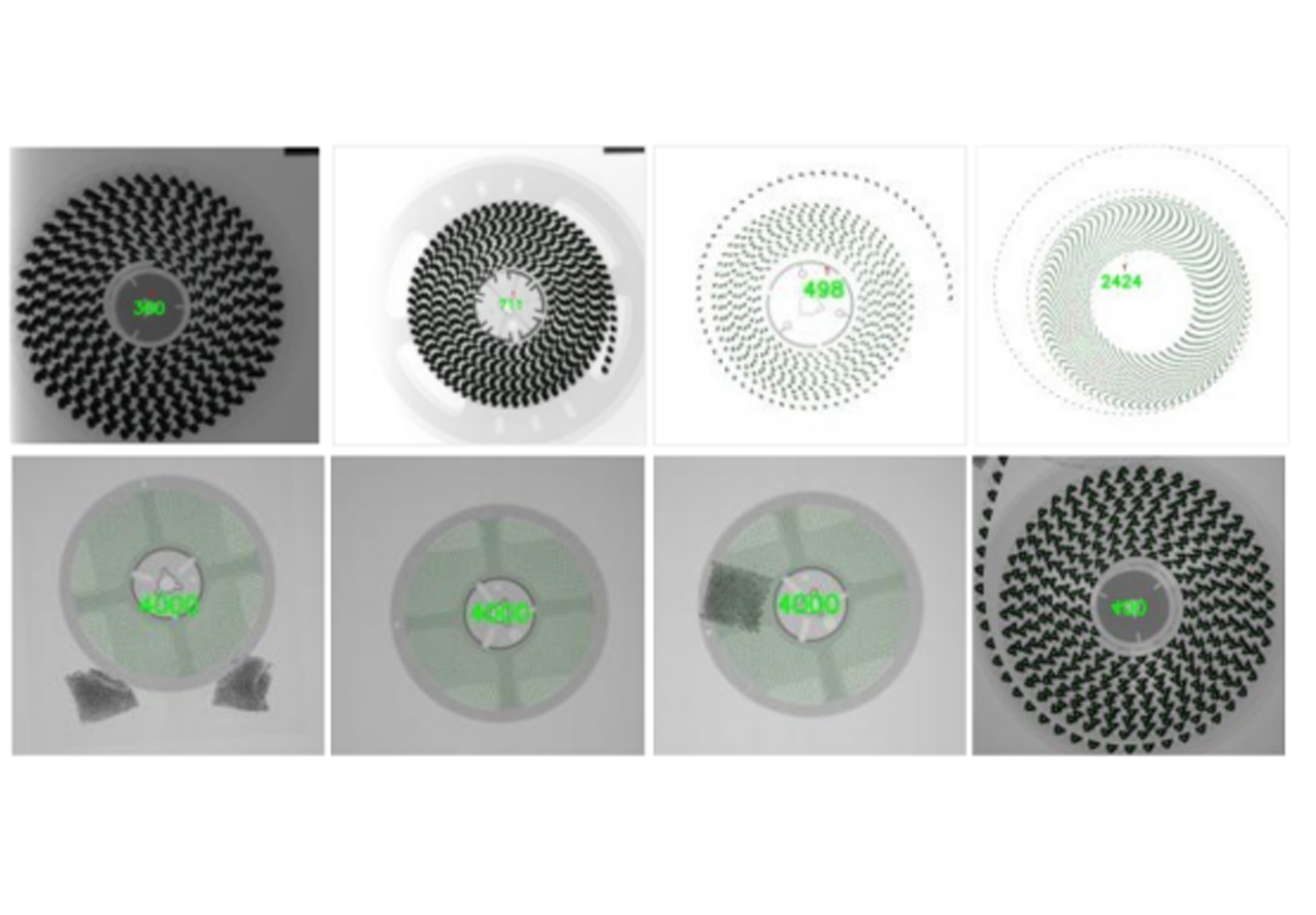

Automated Intelligent Counting

Automated Intelligent Counting for X-ray counters boosts efficiency and accuracy in inventory and quality control. Using advanced algorithms, these systems count items and detect defects in real time, reducing manual labor and errors. Intelligent counting ensures reliable data, quick reporting, and better decision-making, streamlining processes and enhancing accuracy across industries

MES/ERP/WMS system integration

Integrating Nectec X-ray inspection machines with MES, ERP, and WMS systems boosts efficiency through real-time data access and improved traceability. This streamlines workflows, enabling seamless communication between production and inspection. It ensures accurate inventory management and detailed reporting, helping identify trends and enhancing quality control in manufacturing operations.

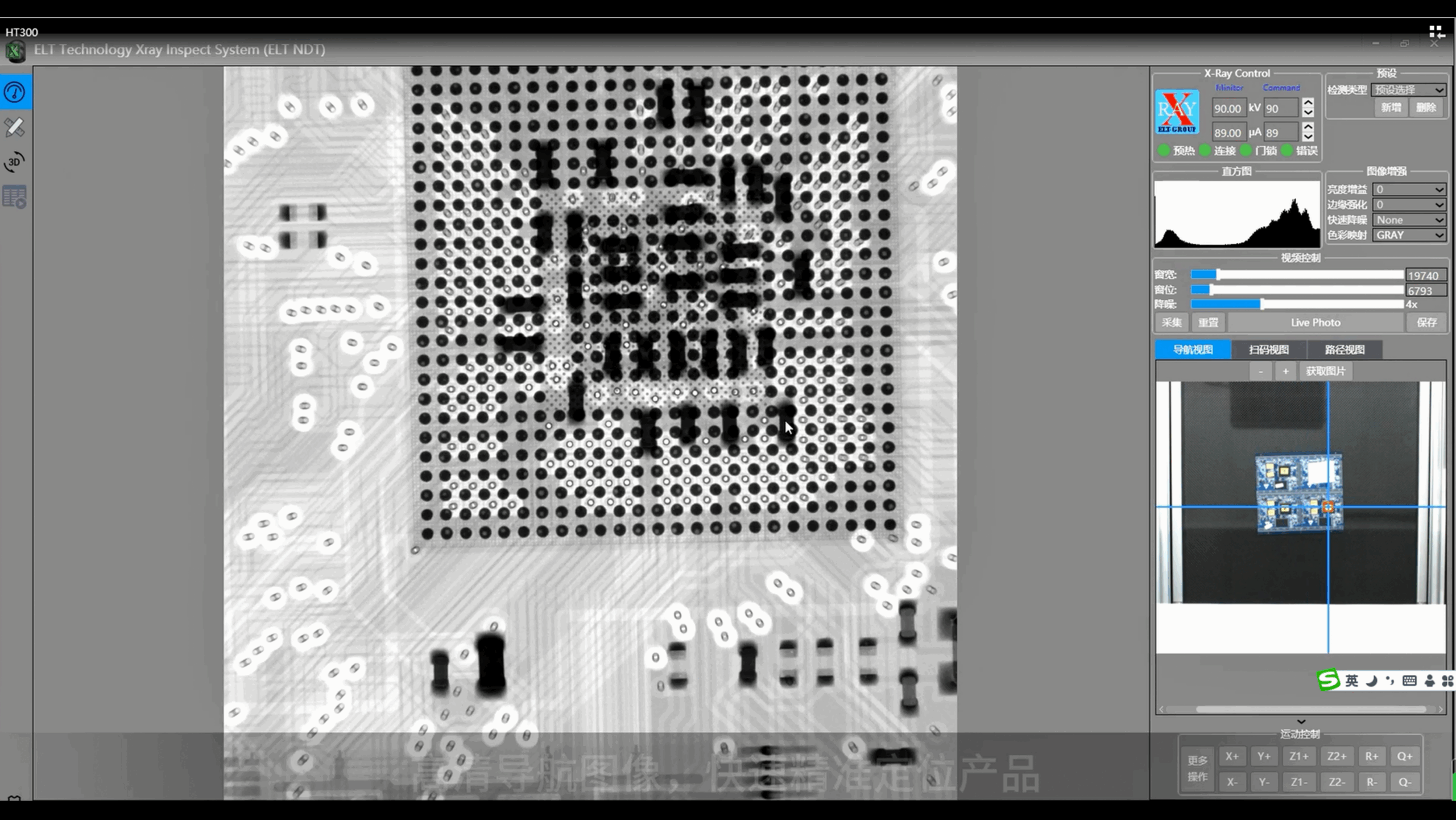

User friendly software interface

The Nectec X-ray inspection machine features a user-friendly interface to enhance efficiency. Intuitive navigation and real-time visualization allow easy monitoring and adjustments. Customizable dashboards provide quick data access, while automated reporting simplifies compliance. Integrated tutorials and support help optimize system use, reducing errors and improving inspection effectiveness.

QR Code Scanning System

Implementing QR code scanning in the Nectec X-ray inspection machine enhances efficiency and accuracy. With an integrated camera, the system tracks items, logs inspection results, and maintains detailed records. A user-friendly interface ensures quick access to real-time data, while secure data management streamlines storage and retrieval, optimizing the inspection process.

Automatic Door

The automatic door system in Nectec X-ray inspection machines uses proximity and safety sensors to detect objects and people. A microcontroller controls the motorized door for seamless opening and closing. Safety features like emergency stops and manual overrides ensure compliance with regulations while boosting operational efficiency.