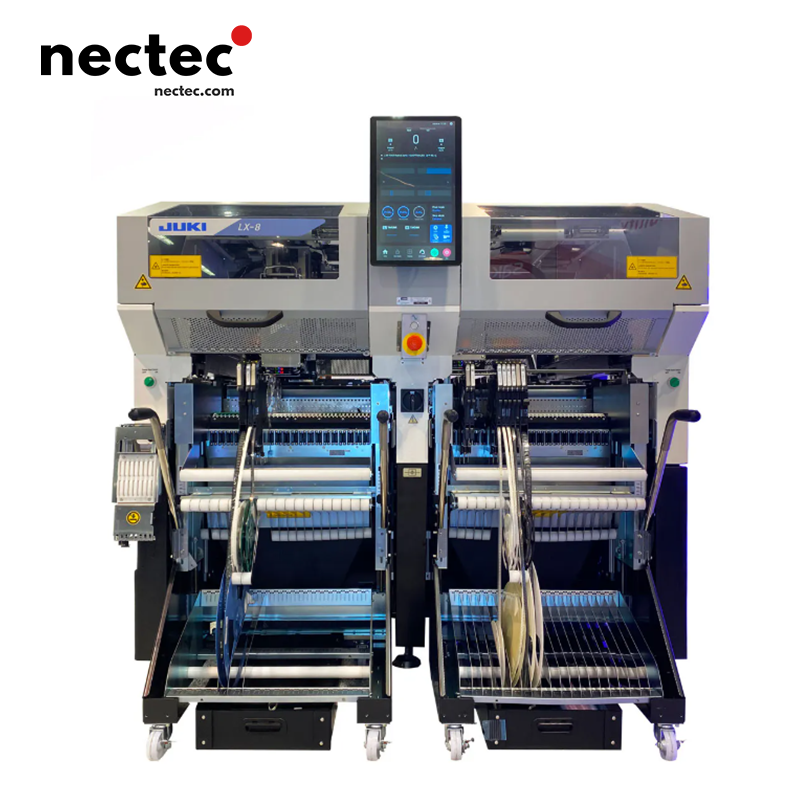

PICK AND PLACE MACHINE

Acclelerate Your SMT Line Better Faster Stronger With Nectec

Extensive Brand Portfolio

Nectec provides a comprehensive range of pick and place machines to meet your SMT assembly needs. Their selection includes equipment from leading manufacturers such as Hanwha/Samsung, JUKI, Yamaha, Fuji, and Panasonic, as well as Nectec's own pick and place machines

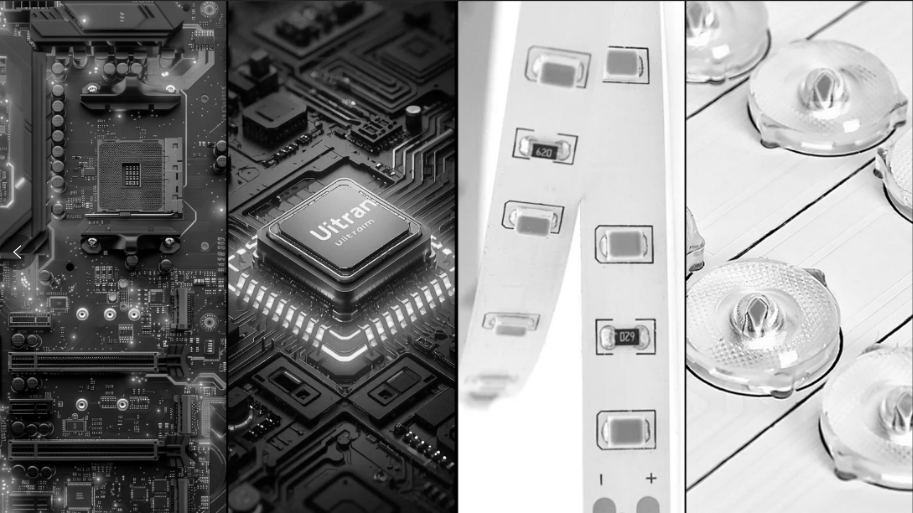

Versatile Solutions for Diverse Industries

- LED Pick and Place Machine

- DOB Pick and Place Machine

- LED Lens Pick and Place Machine

- ODD Shape Pick and Place Machine

- High Speed Pick and Place Machine

- Multifunctional Pick and Place Machine

High End And Cost Effective Solution

NECTEC Advance Intelligent Configurations:

Making Equipment Operation

More Convenient, Smarter, and More Flexible

- Implement offline program allocation

- Automatic selection of component

- data for the entire line

- Intelligent production line system management

- Automatic collection of production line data

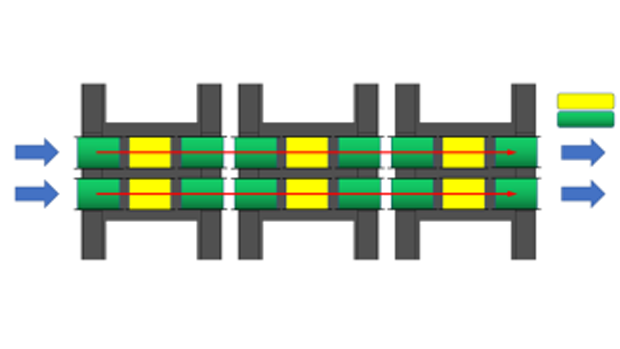

Dual-Track Configuration for High Production Efficiency

Independent placement: Two tracks can independently produce different substrates without interference, achieving higher efficiency. Alternate placement: The front and rear placement heads can simultaneously operate on a single substrate without interfering with each other.

High-precision Multifunctional Head

Equipped with the New 0624R High-precision Placement Head, the R-axis is Controlled by a High precision Servo Motor. It Can Handle Imperial 0201 Microchips to L40*W40*H25mm Large/Irregular Components, Achieving High-precision and Fast Placement.

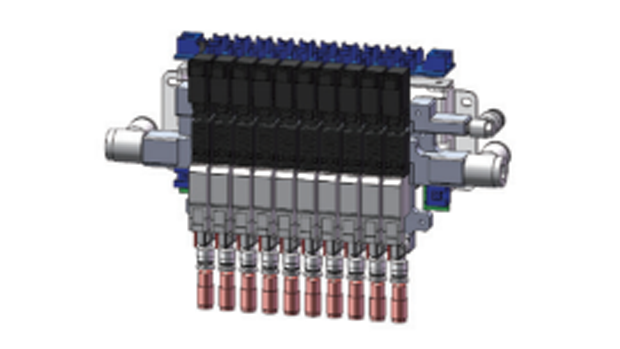

High-speed Placement Head

Equipped with a New Lightweight 10-head Highspeed Placement Head with Flying Cameras, It Can Handle 0201 Microchips to L12*W12*H6.5MM Regular Components. The Z-axis of the Placement Head Uses High-precision Linear Motors to Ensure Component Placement Accuracy of ±0.035mm, Achieving Highefficiency Placement.

Intelligent Smart Feeder

A newly developed high-precision feeder guarantees accurate feeding of 0201 microchips and supports components with specifications of 8, 12, 16, 24, 32, 44, 56, 72, and 88 mm. These advanced smart feeders also enable complete component traceability.

Tray Feeding System

Newly Upgraded IC Tray with Servo High-precision Rail-based Tray Feeding Capability, Supporting Up to 20 Tray Slots and Online Tray Change Without Stopping the Machine.

One click Dock cart

Newly designed fast moving platform, Dock cart can be prepared in advance. One click fast and quick line changing. Single cart 50 Feeder slots (8mm)

Calibration of the material pickup center position

The programming software for the NECTEC Pick and Place machine can automatically identify and calibrate the strip material retrieval center.

Real-time Vacuum Monitoring

Performs self-check of vacuum before picking to confirm the optimal vacuum value. After picking, the vacuum level is checked to ensure proper material pickup, avoiding unexpected losses during transport.

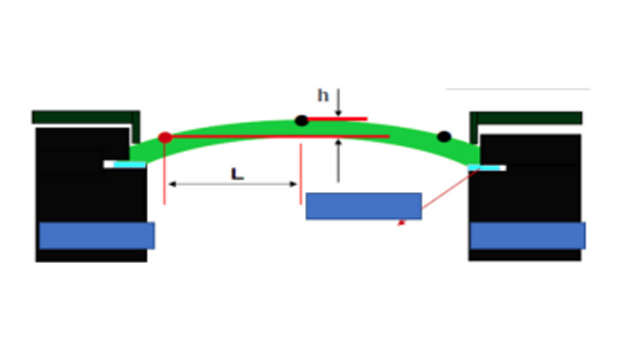

Substrate Warping Detection

Nectec’s substrate warping detection function uses lasers to detect substrate warping, automatically calculates the surface curve, and adapts the placement height compensation. Users can freely set measurement positions according to their needs.

Robert Doe

Nectec specializes in delivering customized solutions tailored to meet the unique needs of each customer. Their expertise ensures optimal performance and efficiency for your specific application.

Shawn Dennis

Nectec’s expert engineering team offers tailored solutions to help customers select the ideal pick-and-place machine. They assist in designing new production lines and calculating estimates to meet production target with precision and efficiency.

- Frequently asked questions

Can Led Pick-And-Place Machines Mount Dob Components?

1588875@qq.com2025-06-18T06:24:37+00:00LED pick-and-place machines have limited capability for mounting DOB components. They can mount DOB components if the size is within 12×12 mm, ensuring compatibility with smaller designs.

What Is Led + Dob Smt Line?

1588875@qq.com2025-06-18T06:23:42+00:00A LED + DOB SMT line include one LED pick and place machine and a DOB pick and place machine. LED pick and place machines are dedicated to mount LED components in high speed. Meanwhile DOB pick and place machine mount only DOB components with precision. Combination of 2 machines make production line more efficient, faster and cost effective production.

Role of Pick and Place Machine In SMT Line?

1588875@qq.com2025-06-18T06:05:08+00:00The Pick and Place (P&P) machine is the core of any Surface Mount Technology (SMT) line. It precisely places surface-mount components (SMDs) onto printed circuit boards (PCBs). Its speed, accuracy, and component handling capabilities directly define the overall throughput and capability of the entire SMT assembly line.

What Are The Advantages Of NECTEC Pick-And-Place Machines?

1588875@qq.com2025-06-18T06:08:16+00:00NECTEC, a leading Chinese Pick and Place machine manufacturer, offers machines with high speed and accuracy, capable of mounting 0201 components to large BGA and CSP chips. With options for high-speed and multifunctional heads, we provide flexible, efficient solutions for PCB assembly. And most important the price is competitive.

What Is The Difference Between Nectec And Other Pick-And-Place Machines?

1588875@qq.com2025-06-18T06:10:34+00:00NECTEC offers cost-effective solutions compared to Japanese and Korean brands while maintaining international quality standards. Our machines deliver unmatched speed and accuracy. When it comes to price and quality, NECTEC stands out as the best choice for reliable and efficient SMT solutions.