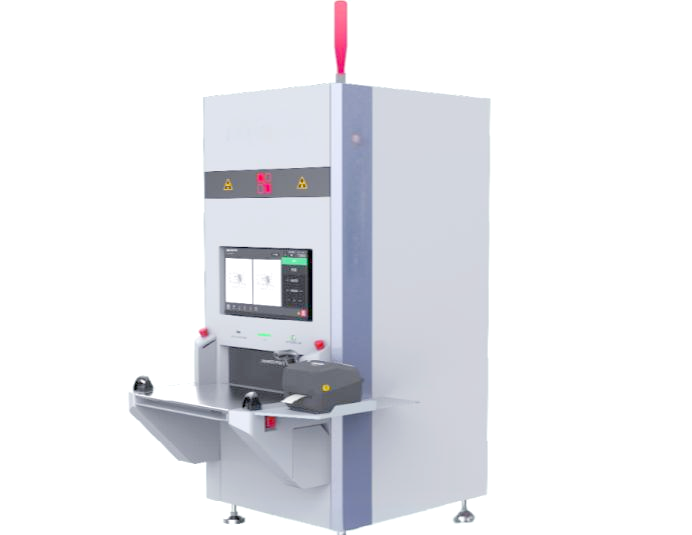

X-ray intelligent electronic inspection machine is used to detect defects inside the circuit boards, casting products, batteries, car wheels and has a wide range of applications. As a versatile and high-precision non-destructive testing device, it plays an important role in the field of electronic and electrical manufacturing. Its core advantages include high-definition image algorithms, BGA bubble detection algorithms, diversified measurement tools, and defect marking functions. These features make it a key component of quality control and widely used in multiple industries. We will analyze the characteristics and functions of this detection equipment. First, let’s take a look at Nectec’s NX-EF X-ray machine. What‘s amazing about this machine is that when zooming while tilting or in a tilted state, the image of the target remains centered on the screen, allowing users to view the target from different angles without frequent adjustments. We will explain three core advantages of this machine along with their usage for the clients.

First advantage is CNC automatic positioning technology. CNC automatic positioning technology is one of the core advantages of this product. When zooming in or out while tilting the device or in a tilted position, this technology ensures that the image of the target object remains centered on the screen, providing users with great convenience. Regardless of the angle from which the target is viewed, users can easily obtain a clear image without having to frequently adjust their viewing position.

This technology significantly enhances the user experience, making the product stand out among many others. What makes this advantage stands out is that it comes with an intelligent navigation and point selection programming system, which makes operations more efficient and faster, while also upgrading production capacity to easily handle batch processing requirements. The system is simple and intuitive to use, easy to learn, and features an automatic image-saving function with a viewable history log, providing users with significant convenience.

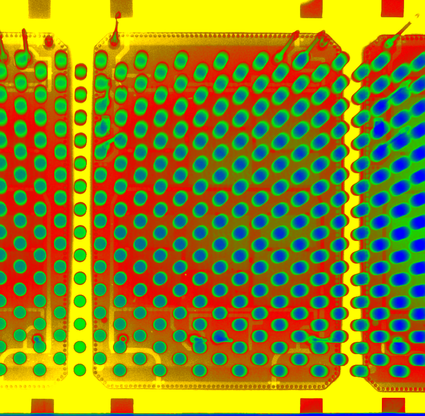

Second advantage is high-magnification lossless enlargement function. This advantage features a unique high-magnification lossless zoom function, enabling users to observe and edit images with greater precision and ensuring that no details are lost during the magnification process. This feature significantly enhances operational accuracy and efficiency, delivering a completely new user experience. What makes this advantage stands out is that it comes with an up to 125 times of geometric magnification. What it does is that it can detect minute features and which enables users to easily detect minute image features. This feature has significant value in many fields, such as medical diagnosis and industrial inspection, bringing users unprecedented convenience and efficiency.

Third advantage is high-definition navigation system function. This advantage not only has high magnification capabilities, but also provides high-definition navigation functions, providing users with precise guidance when detecting small features. This core advantage allows users to more efficiently locate and analyze subtle differences in images, further improving detection accuracy and efficiency.

Two of the key points that are worth mentioning is that it comes with a 1536 x 1536mm pixel matrix, 130 x 130mm effective imaging area with precise operation in one step, and a 360-degree rotation design on the R axis. What makes this advantage stands out is that it has extended the detection range up to 2.5D. So that it can achieve multi-angle defect visualization and improve the detection efficiency of issues such as cold soldering.

To conclude, within the extensive detection range expanded to 2.5D, Nectec’s technology has been successfully applied across multiple industries. One real-world example is in the electronics manufacturing sector. By enabling multi-angle defect visualization, Nectec has significantly improved the detection efficiency of issues such as cold solder joints, delivering substantial benefits to customers. Additionally, this technology is widely adopted in high-end manufacturing sectors like automotive and aerospace, providing robust support for customers’ quality control and production efficiency. Nectec’s NX-EF plays a crucial role in multiple electronic fields, including automotive electronics, energy electronics, home appliances, consumer electronics, and semiconductor-related industries. The device efficiently detects various components such as SMT, BGA, packaged components, IGBT, semiconductor components, precision structural parts, and connectors, ensuring product quality.