When the PCB board of a smartphone motherboard is as small as a fingernail yet must accommodate hundreds of micro-components, even a 0.05mm placement deviation is sufficient to render an entire batch of products scrap. This vividly illustrates the severe challenges faced by SMT assembly processing—how to achieve stable and efficient production under micron-level precision requirements? The solution lies in the synergistic optimization of equipment, processes, and management; any oversight in any stage could become a bottleneck in achieving higher precision. Now let’s dive deep into these reasons behind this technical breakthrough.

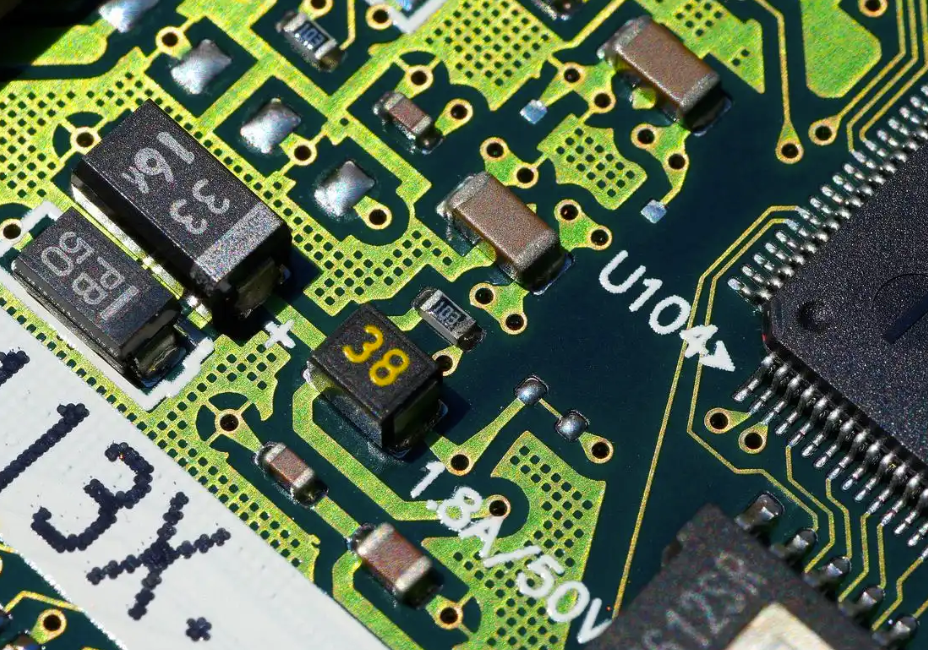

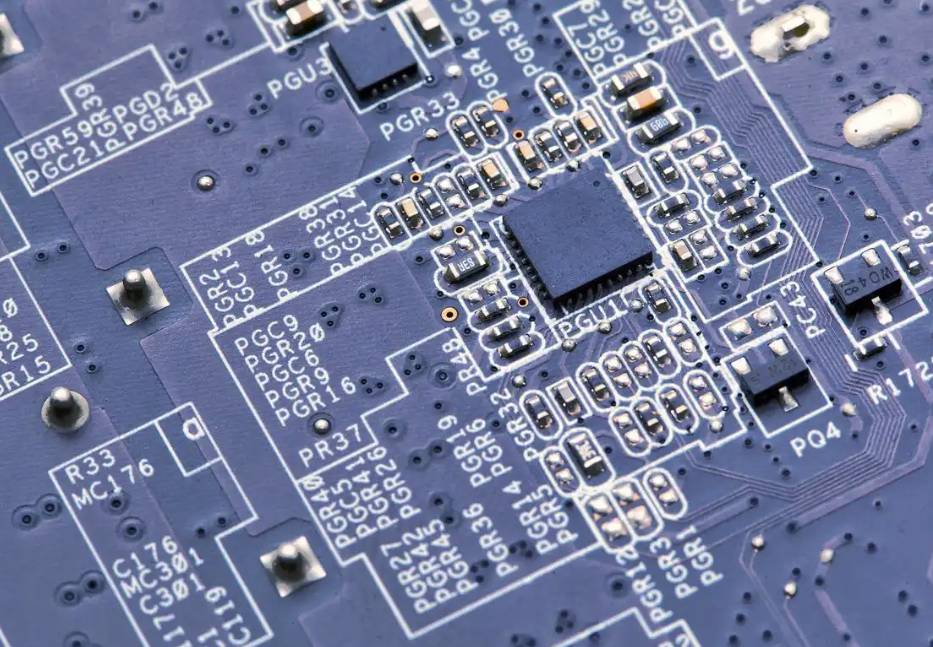

First, machine performance is the hardware foundation for improving accuracy. The reason is because Modern high-end pick-and-place machines have achieved an R-axis rotation resolution of 0.0024° per pulse, giving robotic arms “micron-level tactile sensitivity.” However, selecting equipment is far more complex than simply comparing parameters; the choice of drive system directly impacts actual performance. Compared to traditional ball screw drives, linear motor-driven X-Y positioning systems reduce translational error by 60%. At Nectec, we have confirmed that after calibration with a laser interferometer, its repeatability accuracy can reach ±12μm, equivalent to positioning the same component 1,000 times in a row with positional variation not exceeding one-eighth the diameter of a human hair.

Second, process optimization can bring dynamic balance between extensive and intensive approaches. The reason is because load balancing in the process is not a simple task allocation but requires intelligent support from dynamic algorithms. By continuously monitoring the operational status of dual pick-and-place machines in real time, the intelligent scheduling system can control the difference in placement time to within 3%. An even more sophisticated strategy involves component layout optimization, such as concentrating the placement of 0402-packaged resistors and capacitors, which can reduce the frequency of pick-and-place head changes by 40%. At Nectec, after optimizing the placement sequence, the continuous placement time for components of the same type was reduced from 8.5 seconds to 5.2 seconds, achieving a 38.8% increase in efficiency. Additionally, by reducing the idle movement of the robotic arm, positioning accuracy was simultaneously improved by 15%.

Third, quality closed loop represents passive inspection to active defense transformation. The reason is because quality control requires the establishment of a comprehensive defense system, and incoming material inspection is often the first line of defense that is overlooked. For every 1 ppm difference in the thermal expansion coefficient of a PCB board, there will be a 0.01 mm positional shift after reflow soldering. Establishing an incoming material database to record the CTE values of each batch of substrates allows for advance compensation of program coordinates, thereby preventing problems before they arise. The deployment strategy for online inspection systems, such as AOI, is equally critical—setting up a first-piece inspection station immediately after the pick-and-place machine can provide offset data feedback within 15 seconds, identifying issues two hours earlier than traditional end-of-line inspection methods and improving defect interception efficiency by 800%.

Fourth, smart empowerment provides a future vision for precision management. The reason is because industrial 4.0 technologies are opening up new avenues for improving precision. The application of digital twin technology in the new product introduction phase uses 3D simulation to predict placement deviations under different process parameters, reducing actual debugging time from 8 hours to 90 minutes. Machine learning algorithms demonstrate deeper insights. At Nectec, by analyzing three years of component placement data, we found that for every 10% increase in environmental humidity, the positional deviation of 0201 components increases by 0.7 μm. The compensation model established based on this finding reduces seasonal precision fluctuations by 72%. These technological advancements are redefining the boundaries of precision management.

Fifth and last, it’s best to find the optimal balance between accuracy and efficiency. The reason is because pursuing ultimate precision comes at a cost: when placement speed exceeds 60,000 points per hour, each 1μm increase in precision results in an 18% increase in equipment energy consumption. Therefore, establishing a precision-efficiency KPI matrix is crucial: automotive electronics should adopt a “precision-first” mode, while consumer electronics can enable a “balanced mode.” The focus of future competition has shifted from a single precision metric to “comprehensive manufacturing capability.” We can also see that X-ray inspection machines will occupy a leading position in emerging fields such as 5G millimeter-wave devices and AR glasses micro-displays, and the future of this field is promising.