In modern electronics manufacturing, products are becoming increasingly miniaturized and integrated, with component spacing measured in micrometers—details that are simply invisible to the naked eye, let alone detectable for internal defects. It is precisely in this context that X-ray non-destructive testing technology has emerged as the industry’s “microscope,” particularly the “online X-ray inspection” system. This system has transformed the entire quality control process from “sampling inspection” to “full inspection” and from ‘manual‘ to “automated,” significantly improving yield rates and production efficiency. In this passage, we want to discuss what kind of solutions X-ray inspection machines can provide to the industry and its prevalence in the manufacturing process of cellphone chips, drones.

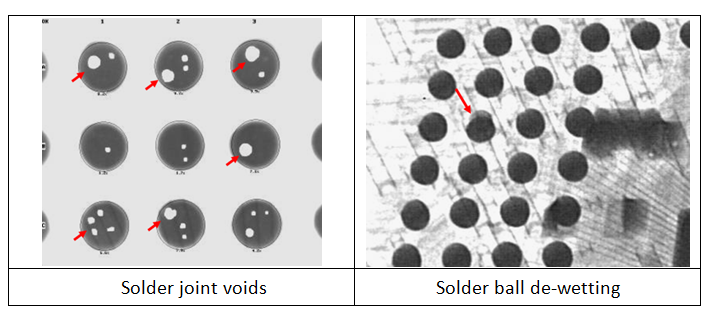

First, we would like to mention the challenge of hidden defects in electronics manufacturing. To begin, we need to understand that with the rapid development of 5G, artificial intelligence, and the Internet of Things, the complexity requirements for circuit board design in terminal devices are becoming increasingly stringent. Take the mainboard of a smartphone as an example: a circuit board the size of a palm is densely packed with hundreds of chips, capacitors, resistors, and other components. Many of these critical components are packaged using BGA (Ball Grid Array) or CSP (Chip-Scale Packaging) technologies, where the solder joints are hidden beneath the chip. Traditional visual inspection and AOI (Automated Optical Inspection) methods are simply unable to determine the quality of the soldering. Similarly, for devices like drone controllers, electric tool drive modules, and industrial camera main control boards, the internal circuit integration is no less complex than in consumer electronics. If issues like solder voids, cold solder joints, or short circuits occur, it can easily lead to unstable device operation, signal interruptions, or even system crashes, with consequences that should not be underestimated.

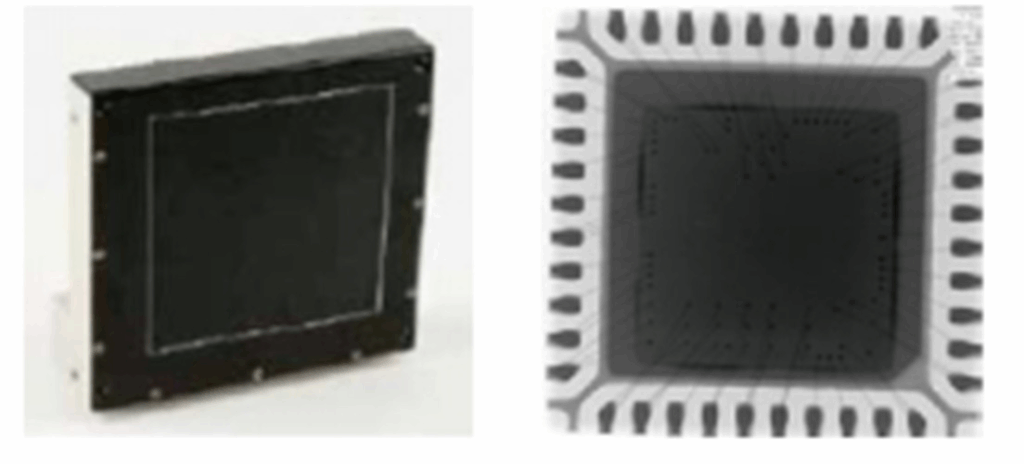

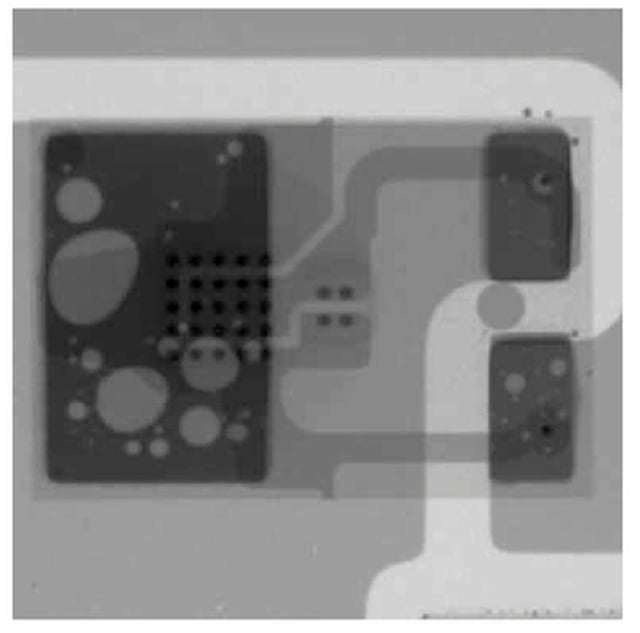

Second, we would like to mention the values of online X-ray inspection machines. X-ray inspection, which is a technology that uses high-energy rays to penetrate objects and form images, can “see through” the internal structure of components, directly observing the condition of solder joints, connection integrity, and material defects. Unlike traditional offline inspection, online X-ray systems can be seamlessly integrated into production lines to achieve automatic feeding, automatic scanning, automatic judgment, and data feedback. There are four areas that can maximize the values of online X-ray inspection machines. Value one is full coverage of scan: what it does is that it does not rely on random sampling anymore, every board and every chip can be scanned and inspected; Value two is real-time feedback: what it does is that it can instantly identify defects and sound an alarm, preventing defective products from entering the next process; Value three is closed-loop traceability: what it does is that it provides test results that are connected to the MES system, facilitating quality analysis and traceability management; Value four is micron-level precision: what it does is that the results clearly show the structure of BGA solder balls, IC pins, internal bubbles, etc. The benefits of using such X-ray inspection machines, like Nectec‘s NX-CT160 online X-ray inspection machine, are unlimited. During X-ray inspection process, a chip solder ball collapse was discovered on the targeted electronic item. By promptly changing the soldering parameters, subsequent large-scale scrapping was avoided. Similarly, after reflow soldering, X-ray inspection can immediately detect potential hidden problems such as cold solder joints and bridging on drone control boards, greatly improving factory stability.

Third, we would like to mention the wide range of application scenarios for such X-ray inspection machines. Although initially used for consumer electronics such as mobile phones and tablets, online X-ray inspection has been increasingly applied to other fields in recent years due to the widespread demand for high reliability. There are four representative emerging fields. Field one is new energy battery management system: such machines can inspect the quality of solder joints and connection plate welding; Field two is automotive electronic control unit: such machines can verify the filling status of internal vias in multilayer boards; Field three is medical electronic equipment: such machines can monitor the quality of solder joints on main control boards for blood glucose meters, ventilator control boards, and so on; Field four is industrial automation main control module: such machines can make sure that these equipment run in long-term stable operation, such as PLCs and variable frequency drive boards. To finish this paragraph, with the development of advanced packaging technologies such as micro-assembly, heterogeneous packaging, and flip chip packaging, the importance of X-ray inspection is constantly increasing, making it an indispensable part of SMT production lines.

Fourth, we would like to mention the future trends of X-ray inspection machines, in order to make them smarter, more efficient and more integrated under current industrial standards. Today’s X-ray systems are no longer just about “taking pictures.” With the introduction of AI algorithms, they can automatically identify various complex defects and perform intelligent judgment and defect classification. In addition, deep learning technology makes the system smarter with use, and it can even predict defects and make process optimization recommendations based on historical data.

At the same time, the detection system is gradually integrated with manufacturing systems such as MES and ERP, becoming part of the smart factory and continuously improving its level of digitization and intelligence.

To conclude, from smartphone motherboards to drone controllers, from consumer electronics to industrial control systems, online X-ray inspection is quietly playing a significant role. It not only enhances quality management standards in electronic manufacturing but also serves as a critical tool for achieving process visualization and quality control in the context of Industry 4.0. In the future, as components continue to evolve toward miniaturization and three-dimensional design, the application scenarios for X-ray inspection will only become more widespread. Whether you are a manufacturing engineer, quality manager, or professional interested in smart manufacturing, it is essential to recognize the value of this “transparent technology.”