As the market penetration rate of new energy vehicles exceeds 40%, the iteration speed of power battery testing technology far exceeds that of traditional automotive components. However, second-hand SMT equipment generally suffers from issues such as aging battery testing modules and insufficient accuracy, becoming an “invisible bomb” that constrains production line efficiency and safety. This article starts from the pain points of the industry and deeply interprets the core technologies and implementation paths for upgrading battery testing modules, providing reusable renovation guidelines for automakers and equipment manufacturers.

Comparing with the adoption of SMT mounting and inspection technology using renewable energy, there are some disadvantages of the second hand SMT mounting and inspection technology specifically for the field of vehicle battery. They are:

First, precision fault. Traditional second-hand equipment mostly uses contact probes for measurement. When dealing with micron-level critical parts such as new energy battery terminals and adhesive areas, the error rate can be as high as 15%-20%, which is difficult to meet the consistency requirements of automobile manufacturers for battery modules.

Second, efficiency bottleneck. Manual programming of the inspection process accounts for more than 30% of the total working hours, while the iteration cycle for new energy vehicle models has been shortened to 8-12 months. Outdated equipment is unable to meet the demands of rapid production changes.

Third, potential safety concerns. Un-upgraded detection modules cannot identify defects such as metal foreign objects inside the battery cells or folded electrode sheets, which can easily lead to thermal runaway risks in battery packs. The accident rate for used equipment is 2.3 times higher than that for new equipment.

To address such issues and challenges, there are four potential paths to not only improve the accuracy of the inspection but to upgrade the intelligent inspection engine.

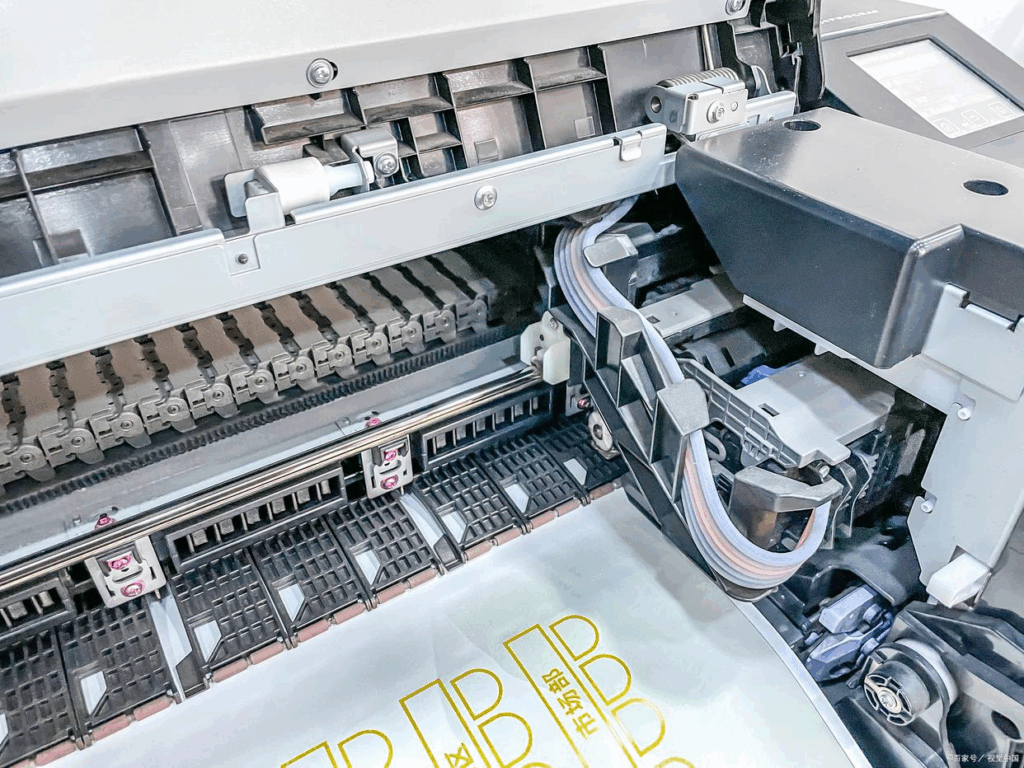

Path one, high-precision composite sensing technology for breaking through the micron-level detection ceiling. It comprises two functions: laser + image dual-mode measurement and AI visual compensation algorithm. First function integrates with Nectec‘s imaging device and laser scanning probe, it achieves 3D contour scanning of battery casings (accuracy of 1.8 μm) and simultaneous measurement of tab dimensions, improving inspection efficiency by 70%. Second function integrates through the AI mechanism model of Nectec SMT inspection x-ray machines, the positioning deviation caused by mechanical wear of second-hand equipment is dynamically corrected, and the alignment error of the electrode sheet is controlled within ±0.05mm.

Path two, cloud-based collaborative detection system for enabling old equipment to think like humans. It comprises two functions: production and testing simultaneously, and one-click program migration. First function integrates Nectec‘s online x-ray inspection machine NX-E6LP and its detection data, automatically upload it to the cloud in real time for big data comparison, and SOH (state of health) assessment reports are generated simultaneously, enabling “Detect-as-a-Service.” Second function integrates Nectec NX-E6LP‘s data management software system, the new model detection parameters are automatically adapted to used equipment, reducing the changeover and debugging time from 48 hours to 4 hours.

Path three, non-destructive testing technology for giving insight into the “black box” of electric cells. It comprises two functions: miniature industrial CT integration solution and thermal expansion dynamic monitoring. First function integrates and embeds Nectec NX-E6LP‘s CT inspection module at the end of the SMT production line to perform 3D imaging of the finished battery cells, accurately identifying nine types of defects, including metal particles and welding pores (defect detection rate > 99.2%). Second function integrates the Nectec NX-E6LP‘s precision control module to monitor changes in the outer diameter of the battery in real time during charging and discharging, and provide early warning of the risk of bulging.

Path four, hardware zero-cost renovation for lightweight upgrade strategy. It comprises two functions: modular plug-in design and reuse of old probes. First function uses the hardware adaptation solution of Nectec and adds the AD620 current detection module to improve the current collection accuracy of second-hand equipment to 0.1 mA. Second function integrates the original contact probe a nanocoating, where it can extend its service life by three times. Which is compatible with aluminum shell batteries and new solid-state battery testing requirements.

To conclude, the battery inspection upgrade for second hand SMT equipment is not a simple hardware replacement, but rather a reconstruction of production line value through technological innovation.

Only by deeply integrating the three key elements of precision, efficiency, and safety can one remain invincible in this wave of new energy equipment transformation.