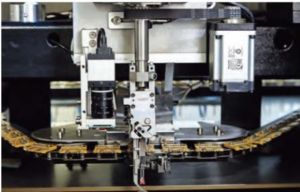

NI-R20E | Super Series Integrated Radial Insert Machine

The NI-R20E is a Series Integrated Radial Insert Machine, primarily designed for small-space, low-partition, and small-sized PCB manufacturing scenarios. It is tailored for customers with limited part numbers, limited workshop space, and small PCB sizes, effectively solving space constraints while ensuring insertion efficiency and accuracy. It is suitable for small- to medium-volume electronic manufacturing scenarios, such as PCB assembly for small power supplies, mini home appliances, and micro control boards.

NI-R20E | Super Series Integrated Radial Insert Machine

- Beschreibung

Beschreibung

Mehrere Designs, um den unterschiedlichen Anforderungen verschiedener Kunden gerecht zu werden.

NI-R20E ist ein kleines und praktisches Modell, das speziell für Kunden mit weniger Materialstationen, geringem Platz in der Werkstatt und kleinen Leiterplatten entwickelt wurde. Es löst Platzprobleme effektiv und erreicht eine tatsächliche Einsteckgeschwindigkeit von 0,26 s/Punkt (im besten Fall). .

Spezifikation

Artikel | NI-R20E | |

Theoretical Speed | Approx20,000 CPH | |

Insertion Direction | 0°-360°,1° increment(-180°-180° Option) | |

Lead Span | 2.5mm/5.0mm; 2.5mm/5.0mm/7.5mm; | |

5.0mm/7.5mm/10.0mm; 2.5mm/3.5mm/5.0mm; | ||

2.5mm/5.0mm/7.5mm/10.0mm Selectable | ||

Größe der Karte | Max 300*245mm | |

Process Height | 900+20mm | |

Dicke der Platte | 0.79-2.36mm | |

Bauteil Höhe | Max 23mm ; Option 26mm | |

Component Style | Capacitor, Transistor, Triode, LED, Mini Switch, Resistor, Connector, Coil,Potentiometer,Fuse Block,Other Radial style taped components | |

Cut & Clinch Length | 1.2/1.5/1.8mm (Selectable ) | |

Clinch Angle | 25°-45° External Bending ; | |

3.5mm Lead Span Internal/External Bending Selectable | ||

3.5mm / | ||

Component Stations | 10—12 STD (15 STD Option ) | |

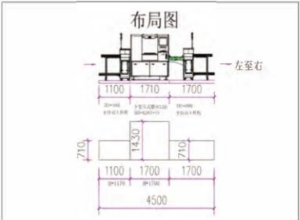

Machine Dimension | Main Body :1800xW1600xH1700mm | |

Gewicht | Main Body : Approx 1100kg | |

Leistungsbedarf | AC220V,Single Phase,50/60Hz,1.5Kw | |

Power Protection | UPS()15 minutes duration after power cool-off ( Option ) | |

Luftdruck | 0.6 Mpa | |

Luftverbrauch | 0.3 M³/min | |

Environmental Temperature | 20℃ ± 10° | |

Noise Level | Approx75 dB(A) | |

Clinch Module Movement | AC Servo Motor (Up,Down) | |

Tape Cutter | Single Stroke Cutting Feature | |

Station Feeding System | STD valve | |

Component Transfer Assemble (CTA) | Cylinder | |

Position Teaching | Vision System | |

Multi Fiducial | ||

Axis Driving System | AC Servo Motor | |

Data Input Style | USB Port (Excel Format) | |

Operation System | Chinese/English Interface (Windows® Platform) LCD Display | |

Operation Mode | Auto / Semi Auto / Manual | |

Component Density | High Density Insertion Style | |

Worktable Rotation | Conveyor Track | |

Board Inload | Conveyor Inload Left to Right (Selectable) | |

Verwandte Produkte