FX-3RA | High Speed Modular Mounter

JUKI FX-3RA SMT machine** is a high-speed and high-precision SMT equipment that uses 24 nozzles for synchronous placement and new laser recognition technology. It supports 0402 to 33.5mm components (including QFP/BGA), with a theoretical speed of 90,000 CPH and an accuracy of ±0.05mm. It is equipped with a linear servo motor and magnetic suspension drive to ensure stability and efficiency; it is compatible with mixed feeders and extra-long substrates (maximum 800×560mm), and is suitable for diversified production needs such as LEDs and automotive electronics. The modular design and low maintenance characteristics significantly improve the flexibility and reliability of the production line.

JX-350 | Flexible LED Mounter

The new JX-350 LED Mounter offers a flexible placement system specially designed for LED lighting products and mid- to large LCD display backlights. It can support ultra-long boards up to 1,500mm and JUKI laser centering for high speed, high accuracy placement offers the best in the industry.

KE-3010A | High-Speed Modular Placement SMT Chip Shooter

The KE3010A is a 7th generation modular placement machine from Juki and represents the latest leading-edge technology for improved flexibility and production quality.

KE-3020VA | High Speed Flexible Mounter

The KE302V is a 7th generation modular placement machine from Juki and represents the latest leading-edge technology for improved flexibility and production quality. It supports a hybrid feeder mix of electronic and mechanical feeders with up to 160 dual lane electronic 8mm tape feeder capacity per machine. Maximum board size is 22"x24". The KE3020V is the ideal solution for PoP (package on package) placement supporting a linear and rotary fluxer for highly accurate placement.

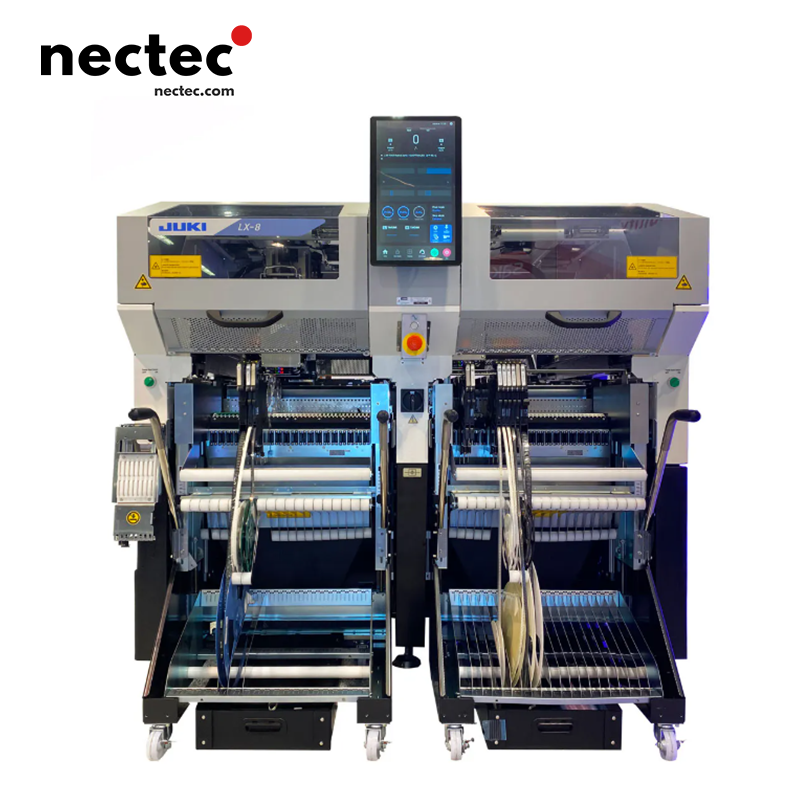

LX-8 | High-speed Flexible Mounter

JUKI's LX-8 is the ultimate solution for any production line. With its cutting-edge technology and versatility, it features double Takumi heads for exceptional performance and precision. Despite reaching top speeds of up to 94,000 CPH, the LX-8 ensures an exceptional accuracy rate of ±30 μm (Cpk ≥1), delivering precision and quality with every placement.

RS-1R | Smart Fast Modular Mounter

The consistent further development of the tried-and-tested technologies from the RS-1R opens up new, outstanding possibilities: Even faster assembly of smallest chips (0201 metric) up to large components of 50 x 150 mm or 74 mm edge length for square components. The base frame of the RS-1R has been completely redesigned for this purpose. The unique Takumi head covers even more different component heights and thus achieves a decisive speed advantage. The 360° visual component recognition allows the secure detection of user-specific polarity marks. Thanks to the RFID integration in the nozzles, these can be traced back completely together with the components and boards. The machine combines the features of a chip shooter with a mounter for large components. The purchase of each special machine type for it eliminates as well as a change of the placement head.

RS-1XL | Fast Smart Modular Mounter

With maximum speed up to 42,000CPH (Optimum) and 29,000CPH (IPC9850), the RS-1XL is designed for maximum throughput. The RS-1XL supports components from 0201 metric (008004") up to 74mm square and 50mm x 150mm rectangular parts for maximum flexibility.

RX-6B | High-Speed Compact Modular Mounter

The compact RX-6R/RX-6B offers high productivity, flexibility and quality – in a compact footprint. This is applicable to dual-lane production.Compact footprint : the width is just 1.25m.Equipped with standard Placement Monitor check function.Replaceable head allow you to configure a production line best suited to the current repirments.High-speed component placement using high-speed non-stop vision recognition.Wide range of components and boards: tall components, large components and large boards.Brand new Matrix Tray Sever TR8S improves the component capability and productivity.

RX-8 | High -Speed Compact Modular Mounter

JUKI RX-8 achieves ultra-high speed (100,000 CPH) and high precision (±40μm) micro-component placement through P20 placement head, high-precision vision system and intelligent feeding management, which is especially suitable for high-density placement scenarios such as consumer electronics and LED lighting. Its compact design and JaNets system support efficient production line integration and process optimization, and is a benchmark for SMT equipment that takes into account speed, precision and flexibility.