SMT chip mounting technology is widely used in many fields due to its high efficiency, precision, and adaptability. The following are some of the main areas of application.

First, consumer electronics. The followings are the categories. Smartphones and tablets: SMT surface mount technology is widely used in the assembly of components such as motherboards, camera modules, and battery management systems in smartphones and tablets; Audio and video equipment: For example, televisions, audio systems, and DVD players, where a large number of components on the internal circuit boards are assembled using SMT surface mount technology; Wearable devices: For small, lightweight electronic products like smartwatches and health monitors, SMT technology is key to achieving high integration and miniaturization. For such small sized chip components mounting tasks, our Nectec’s NT-B5 high speed pick and place machine provides top-tier accuracy and mounting precision performances for consumer electronics assembly. What makes it outstanding is that it equips with a high-speed 10-head placement system that can handle a wide range of components with an accuracy of ±0.035mm. Not only that, it comes naturally with smart features like an ATC automatic nozzle change system and real-time vacuum detection for quick and user-friendly operations.

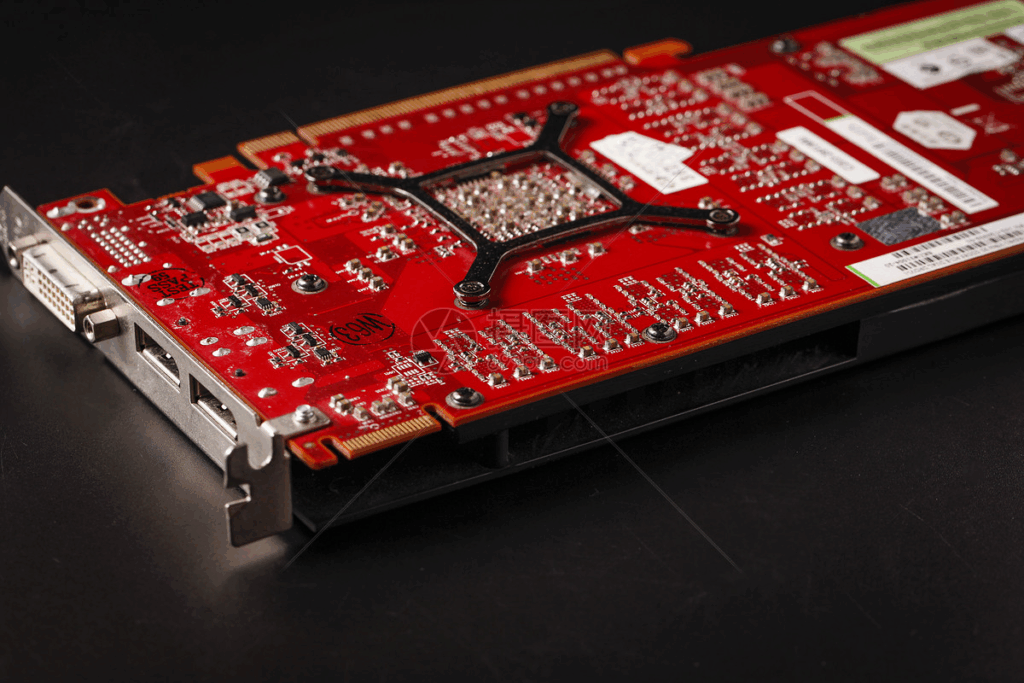

Second, computer and telecommunications. The followings are the categories. Computer motherboards and servers: Key components on computer motherboards, such as CPUs, memory, and chipsets, as well as various boards inside servers, rely on SMT technology for assembly; Network equipment: Communication devices such as routers, switches, and wireless APs also use SMT technology to assemble the components on their internal circuit boards.

For chip components like these that require longevity and stable performances, we recommend our Nectec’s NT-P5, it is the latest high-precision module placement machine designated for microchips like 0201. Not only this, it provides linear scanning camera and flying camera to better perform accurate placement of the microchips for devices like computer motherboards and chipsets.

Third, automobile electronics. The followings are the categories. Engine Control Unit (ECU): The ECU is responsible for controlling the operation of the car engine. It integrates a large number of electronic components, which are tightly assembled on the circuit board using SMT surface mount technology; In-vehicle entertainment system: This includes in-vehicle audio systems, navigation systems, displays, etc. The components on the circuit boards of these systems also widely adopt SMT surface mount technology; Safety Systems: Such as the Anti-lock Braking System (ABS) and Electronic Stability Program (ESP), these systems also require high-precision SMT technology to ensure reliable connections between electronic components. For such high-precision and high-speed placement requirement, we recommend our Nectec’s NT-T5 for handling such tasks. What makes it special is that it can reach an impressive placement speed of 84,000 CPH with its dual-arm combination placement technique, marking it one of the top-tier performing pick and place machines at Nectec.

Fourth, industrialization control. The followings are the categories. PLC (Programmable Logic Controller): A core control device in the field of industrial automation, with a large number of electronic components integrated on its internal circuit board. These components are assembled at high density using SMT (Surface Mount Technology); Sensors and Actuators: Various sensors and actuators used in industrial automation, with components on their circuit boards also commonly assembled using SMT technology. For such high-precision requirement tasks like this, we recommend our Nectec’s NT-P5 for its excellent high-precision multifunctional performance.

Fifth, medical electronics. The followings are the categories. Medical monitors: Medical devices used to monitor patients’ vital signs, whose internal circuit boards are precisely assembled using SMT technology; Medical imaging equipment: Such as X-ray machines and CT scanners, whose internal electronic control systems also rely on SMT technology. Other than our Nectec’s excellent pick and place machines, we also provide 3D CT x-ray and all other multi-purpose x-ray machines for detecting chip component mounting defects.

Sixth, aerospace and national defense system. The followings are the categories. Satellite communication and navigation systems: Communication and navigation modules on satellites require high reliability and high precision electronic component assembly, and SMT chip technology is an important means of achieving this goal; UAV and missile guidance systems:

The electronic systems inside these high-tech devices also rely on SMT chip technology to ensure precise connection and reliability of components. Since reliability and precision are the main concerns, we recommend our Nectec’s NT-B5, NT-P5 and NT-T5 for high reliability and high-precision chip mounting performance.

Lastly, LED lighting. The circuit boards and control modules in LED lighting products are mostly assembled using SMT surface mount technology to achieve efficient, energy-saving lighting effects. For such tasks, we recommend our Nectec’s NT-L12 LED pick and place machine specifically designated for LED lighting high-speed and high-precision chip mounting purpose. This machine gives an exceptional performance and increased production capacity by nearly 50% guaranteed.