In the wave of miniaturization of 5G and IoT devices, X-ray inspection accurately detects micron-level solder joint bridging and voids, thereby pushing the circuit board yield rate to a new height of 99.9%. By optimizing the reflow soldering curve, the bridging defect rate for 0.15mm pitch QFPs has plummeted from 1.2% to 0.08%. AI deep learning and nano-CT technology are paving the way for a “zero-defect” future in electronics manufacturing. However, there are still some challenges and shortcomings that warrant our attention and improvement. Additionally, the effectiveness of X-ray inspection is closely tied to the machine’s core parameters. Therefore, we aim to provide a comprehensive overview of X-ray inspection machines in the SMT field, including their applications, challenges, and future trends.

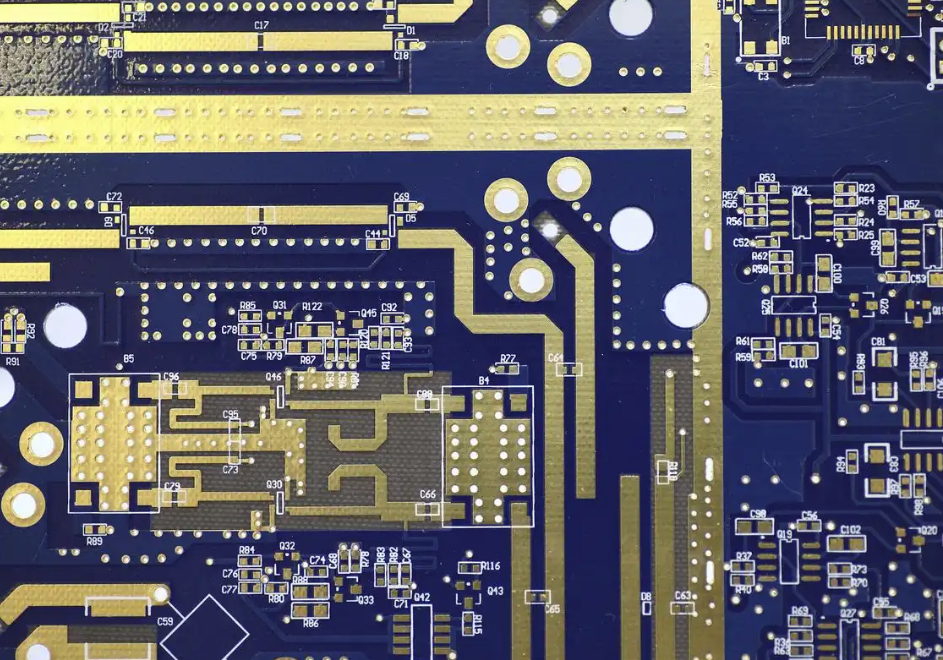

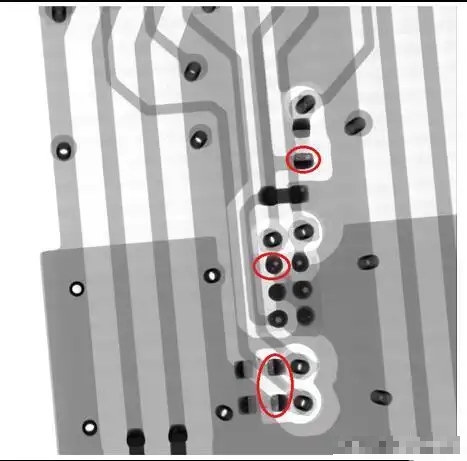

First, we want to discuss some key defects and quality challenges in SMT processes. SMT is a core process in electronics manufacturing, and the quality of its solder joints directly determines the reliability and lifespan of circuit boards. However, in high-speed placement and reflow soldering processes, there are approximately four types of defects that are commonly difficult to identify using AOI. Type one is solder bridging: which is accidental solder connection between adjacent pins, resulting in a short circuit. This type of defect accounts for 15-20% of all defects; Type two is voiding: which is when the proportion of bubbles inside the solder joint exceeds 10%, thermal resistance increases and component life decreases by more than 30%; Type three is cold solder: which is when the solder did not melt completely, causing abnormal contact resistance and intermittent malfunctions; Type four is component misalignment: which is when the BGA/CSP package offset exceeds 20% of the pin pitch, signal transmission will fail.

Traditional AOI can only detect surface defects and is powerless against internal defects in hidden solder joints such as BGA and QFN. X-ray inspection, however, has become the key solution to this problem through its penetrating imaging technology. This is why X-ray inspection machines are currently leading the field in SMT.

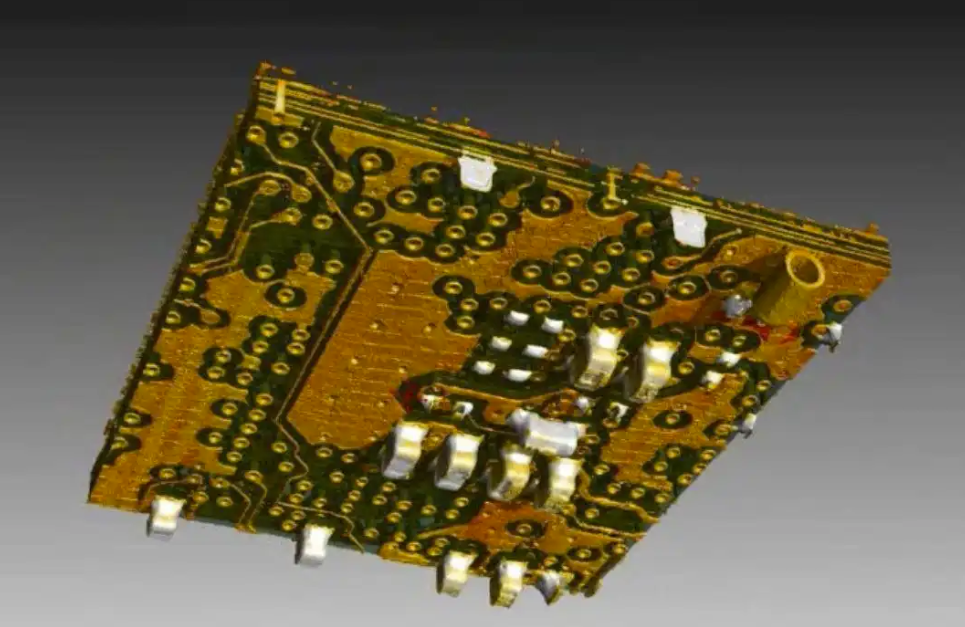

Second, we want to discuss some principles of X-ray inspection technology and core parameters of equipment, focusing on the principle of image formation. There are three principles that are worth mentioning. Principle one is material absorption differences: the reason is because solder, such as tin-based alloys, contrasts with the X-ray absorption coefficients of PCB substrates, such as FR-4 and copper foil. In particular, the attenuation coefficient of tin is 40% lower than that of copper; Principle two is tomosynthesis: the reason is because the machine can reconstruct 3D images through multi-angle projection, with a resolution of 2-5μm, accurately quantifying cavity volume and bridge location; Principle three is AI assist analysis: the reason is because machines can use convolutional neural networks, such as the well-known CNN, to automatically label defect types with an error rate of less than 0.3%, compared to an error rate of approximately 5% for manual visual inspection. Next, we want to quickly mention the impact of industrial-grade standard parameters on SMT inspection. First, with a resolution of ≤1μm, it can accurately identify micro-bridges and voids smaller than 0.1mm². Second, with a detection speed of ≥10 boards per hour, it can match the high-speed production line cycle of SMT lines, such as the Nectec pick-and-place machine, which can achieve a maximum of 84,000 CPH.

Next is radiation dose, which can reach ≤1 μSv per cycle. Since it complies with the IEC 62494 standard, it ensures operational safety and prevents component damage. Finally, penetration capability can reach 120 kV/200 W and supports inspection of 6-layer PCBs and metal-shielded components.

Third, we want to discuss one classic real-life scenario of Nectec’s X-ray inspection machines in SMT production lines from past clients. We have had an automotive electronics manufacturer client discovered bridging of 0.20 mm pitch QFP package pins during X-ray inspection of ECU control board production. By adjusting the reflow soldering temperature curve, the bridging defect rate was reduced from 1.3% to 0.09%.

Fourth, we want to give some future prospect of X-ray inspection machines. First is AI deep learning. The advantage of using it is that it can self-train a defect feature database, such as using the well-known GAN to generate adversarial networks to achieve adaptive process parameter optimization. Next is CT tomography. Mature nanoscale CT equipment, such as Nectec’s NX-CT160, supports submicron-level defect analysis. Finally, there is multimodal fusion. This large-scale model can integrate X-ray, thermal imaging, and acoustic detection data to establish a comprehensive quality monitoring system.

To conclude, the world is now driven by the miniaturization and high-density integration of 5G and IoT devices. X-ray inspection has become a core tool for quality control in SMT processes. By accurately identifying hidden defects such as solder bridging and voids, we can increase the yield rate of circuit board assembly to over 99.9% while reducing quality costs by more than 30%.

In the future, with continued breakthroughs in device intelligence and inspection speed, X-ray technology will further drive the electronics manufacturing industry toward the goal of “zero defects.”