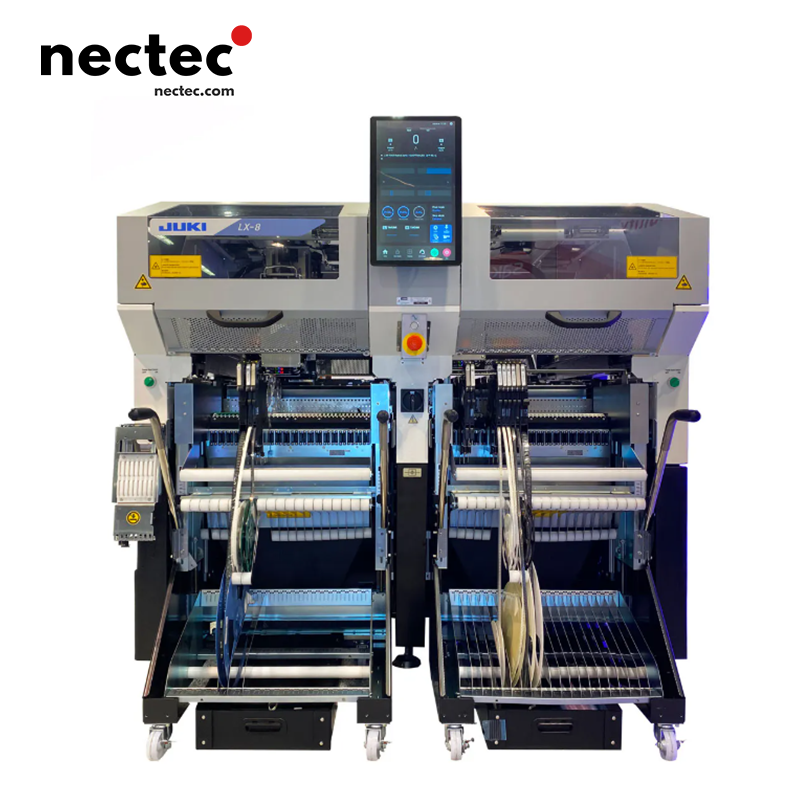

FX-3RA | High Speed Modular Mounter

JUKI FX-3RA SMT machine** is a high-speed and high-precision SMT equipment that uses 24 nozzles for synchronous placement and new laser recognition technology. It supports 0402 to 33.5mm components (including QFP/BGA), with a theoretical speed of 90,000 CPH and an accuracy of ±0.05mm. It is equipped with a linear servo motor and magnetic suspension drive to ensure stability and efficiency; it is compatible with mixed feeders and extra-long substrates (maximum 800×560mm), and is suitable for diversified production needs such as LEDs and automotive electronics. The modular design and low maintenance characteristics significantly improve the flexibility and reliability of the production line.

FX-3RA | High Speed Modular Mounter

- Description

Description

Placement Head & Laser Metrology System

Multi-Head Parallel Architecture

- 24-Nozzle Multi-Head System: Four placement heads with 6 independent nozzles each enable synchronous pick-and-place operations, achieving ultra-high-speed throughput.

- LNC60 Laser Scanning Module: New-generation laser sensor supports parallel component identification across all 6 nozzles, delivering 20% faster recognition throughput than legacy 4-nozzle systems. Covers 0402 (0.4×0.2mm) to 33.5mm² components (QFP/CSP/BGA) with ±50μm (±3σ) measurement accuracy.

- In-Flight Component Verification: Real-time laser inspection during high-speed head transit minimizes idle time and enhances placement efficiency.

Vision & Motion Control System

Advanced Drive Technology

- X/Y Axis Linear Servo Drives: Full closed-loop control with 0.001mm-resolution linear magnetic scales enables high-acceleration motion and sub-micron positioning accuracy.

- Non-Contact Magnetic Levitation: Frictionless linear motor design ensures maintenance-free operation, extended equipment lifecycle, and acceleration performance surpassing traditional lead screw systems.

- Dual-Servo Y-Axis Actuation: Optimizes conveyor stability during high-speed operation to mitigate vibration-induced placement errors.

Feeder System

Hybrid Feeding Ecosystem

- 240-Station Feeding Platform: Supports mixed electric/mechanical tape feeders (8mm equivalent), accommodating up to 240 components for diverse production needs.

- Intelligent Feeding Technology: eFeeders with automatic tape splicing and real-time shortage alerts reduce manual intervention and sustain uninterrupted production.

PCB Handling System

Versatile Substrate Management

- Standard/Extended Form Factors:

- L-type: 410×360mm

- XL-type: 610×560mm

- Extended: 800×560mm for ultra-long PCBs (LED lighting, automotive electronics).

- Servo-Driven Active Damping Platform: Reduces substrate vibration during fixturing, minimizing placement offsets and shortening setup time.

Software & Human-Machine Interface

Intelligent Production Orchestration

- Dynamic Trajectory Optimization: AI-driven algorithms auto-generate optimal placement paths, achieving 90,000 CPH theoretical throughput under ideal conditions.

- 15″ Touchscreen HMI: Intuitive graphical interface for real-time monitoring of placement status, mispick rates, and fault diagnostics.

- Modular Line Integration: Compatible with JUKI KE series for flexible, mixed-model production line configurations.

Vacuum System & Maintenance Design

Reliability Engineering

- High-Efficiency Vacuum Pump: Reduces air consumption while enhancing component pickup stability, lowering mispick rates.

- Tool-Less Modular Maintenance: Quick-change nozzles/feeders and lubrication-free eFeeder design minimize downtime and maintenance costs.

- Maintenance-Free Magnetic Drives: Non-contact levitation technology eliminates mechanical wear, extending service life.

Technical Advantages Summary

- Ultra-High Throughput: 90,000 CPH placement speed via linear servo drives and parallel laser inspection.

- Precision Metrology: ±50μm accuracy for fine-pitch components (QFP/BGA) with Cpk≥1.5 process capability.

- Scalable Flexibility: Supports hybrid feeding, extended-length PCBs, and multi-model line integration.

- Low Total Cost of Ownership (TCO): Magnetic levitation, modular design, and intelligent maintenance reduce operational expenses.

specification

Item/Model | High-Speed Modular Mounter | High-Speed Modular Mounter | FX-3RA(include FX-3RAL and FX-3RAXL) | |

FX-3RAL | FX-3RAXL | feature | ||

Board size | L size(410x360mm) | yes | no | 1. 0402mm(01005 inch) ~ 33.5mm×33.5mm 2. Laser recognition : ±0.05mm(±3σ) 3. On-the-fly centering using integrated laser 4. 2 stations, 4 gantries, 4 placement heads, 24 nozzles 5. Linear servo motor XY drive with full closed-loop control 6. Holds up to 240 components 7. Electrical or mechanical feeder trolley |

L-Wide size(510x360mm)*1 | yes | no | ||

XL size(610×560mm) | no | yes | ||

Applicability to long PWB | 800×360mm | 800×560mm | ||

Component height | 6mm | yes | ||

Component size | Laser recognition | 0402(01005) ~ 33.5mm×33.5mm | ||

Placement speed (chip) | Optimum | 0.040Sec. / chip(90,000CPH)*2 | ||

IPC9850 | 66,000CPH | |||

Placement accuracy | Laser recognition | ±0.05mm(±3σ) | ||

Feeder inputs | Max.240 in case of 8mm tape (on a Electric double tape feeder) | |||