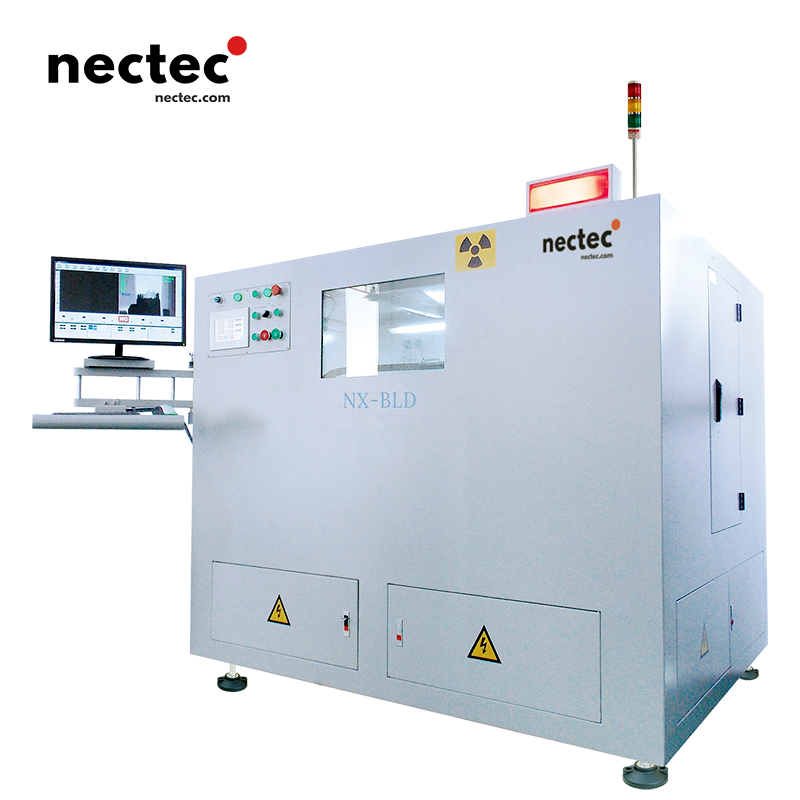

NX-BLI | Battery X-ray Inspection System

The X-Ray machine NX-BLI detects internal battery structures and electrode coatings, ensuring comprehensive inspection of negative electrodes and shell walls. Suitable for 18~26 series batteries, it features a high-speed transmission mechanism for efficient operation. The modular design allows for expansion, with automatic loading/unloading and seamless production line integration. Advanced features include automatic determination, data storage, and defect isolation, achieving full automation with a capacity of 60-120 PPM.

NX-BLI | Battery X-ray Inspection System

- Description

Description

Internal Structure Detection: Detects the internal structure of cylindrical battery ears and the coating of the positive and negative electrode sheets.

Comprehensive Inspection: Inspects the condition of the negative electrode and the shell wall in the battery (spacing, contact distance, bending state of the pole ear, etc.).

Versatile Compatibility: Suitable for detecting 18~26 series cylindrical batteries.

Efficient Operation: High-speed positioning transmission mechanism design for efficient and stable operation. Modular standardized design with strong expansion capabilities.

Expandable Loading/Unloading: Expandable automatic loading/unloading structure based on demand.

Seamless Integration: Can be connected to the user’s automatic production line for unattended operation.

Advanced Features: Features automatic determination, data storage, identification, screening, and isolation of defective products.

Full Process Automation: Achieves automatic control of the entire test process.

High Capacity: Maximum capacity: 60-120 PPM.

specification

Projects | Mode | Technical Parameters |

Light Tube | Tube type | Closed tube |

Tube Voltage | 90kv | |

Tube Current | 200uA | |

Focus Size | 5um | |

Cooling Method | Air cooled | |

Flat Panel | Pixel Size | 85um |

Detector | Pixel Matrix | 1536*1536mm |

Effective Imaging Area | 130*130mm | |

Fps/Rate | 20 | |

Number of A/D bits | 16bit |