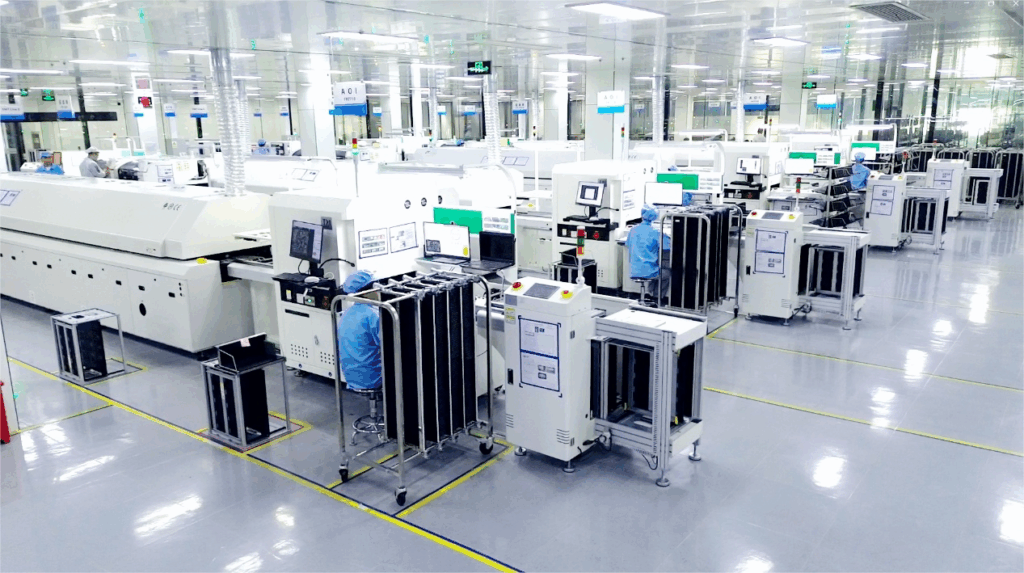

The optimization and efficient production of modern SMT assembly processes involve multi-dimensional technological collaboration, with the core focus on building a precise and controllable manufacturing system. In general, SMT assembly process optimization and efficient production are crucial for enhancing manufacturing performance, reducing costs, and ensuring high-quality electronic products. By optimizing SMT processes—such as solder paste printing, component placement, and reflow soldering—manufacturers can minimize defects, improve yield rates, and increase throughput. Efficient production also reduces material waste, energy consumption, and downtime, leading to faster time-to-market and better competitiveness. Additionally, automation and data-driven optimizations help maintain consistency, scalability, and flexibility in meeting diverse production demands, making SMT assembly optimization vital for profitability and reliability in electronics manufacturing. On the other hand, there are different types of SMT pick and place machines suitable for various working environments and industrial requirements. First one is ultra high-speed pick and place machine, with a speed of 80,000 to 120,000 CPH and precision of ±25μm. Fortunately, our Nectec’s NT-T5 can reach 84,000 CPH in the most optimized situation. Second one is multifunctional pick and place machine, with a speed of 20,000 to 40,000 CPH and precision of ±15μm. Coincidentally at Nectec there’s one model called NT-P5 and can reach 42,000 CPH. Last one is precision dispensing and mounting machine, with a speed of 5,000 to 10,000 CPH and precision of ±10μm. Then, we will introduce the key steps to achieve SMT manufacturing optimization.

First step is the SMT precision welding parameter optimization techniques. In the SMT assembly process, precise control of soldering parameters is a critical factor in ensuring the reliability and yield of solder joints. First, different solder paste thicknesses must be set for different component package types, such as QFN, BGA, or 0201 resistors, typically controlled within the range of 80-150 μm. The CPK value of solder paste volume is monitored in real time using an SPI device to reduce the risk of bridging. During the reflow soldering stage, gradient management of the temperature curve is particularly critical. The preheating zone should be heated at a rate of 1.5–2.5°C/s to avoid thermal stress accumulation, the constant-temperature zone should be maintained for 120–180 seconds to fully activate the flux, and the peak temperature should be precisely controlled within the 235–250°C range based on the solder alloy type, such as SAC305 or SnBi. Additionally, dynamic adjustment of placement pressure must compensate for component weight and PCB warpage. It is typically recommended to use a pressure feedback system to control errors within ±5 N. Through multivariate orthogonal experiments and DOE analysis, soldering parameter combinations can be systematically optimized to reduce solder joint porosity to below 5%, while significantly lowering the probability of component failure caused by thermal shock.

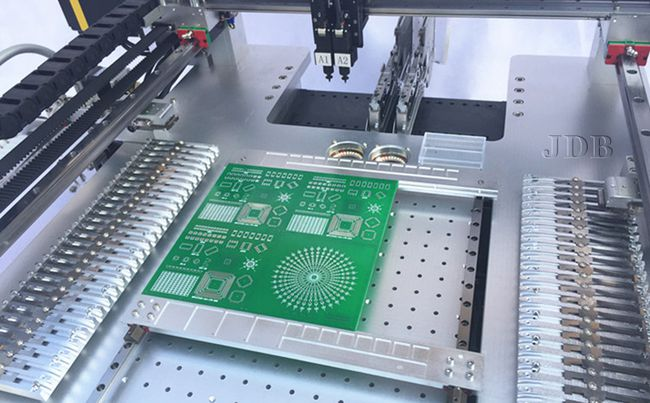

Second step is some recommendations for high-speed pick and place machines selection. In SMT production line planning, equipment selection directly impacts production efficiency and process stability. When evaluating high-speed placement equipment, three core parameters should be prioritized: chip placement speed (CPH) must align with the company’s order volume.

It is recommended to select a model with a 20%-30% higher capacity than current demand to accommodate fluctuations in production capacity; Placement accuracy must be within ±25μm, especially when handling 01005 micro-components or QFN packages, where ±15μm high-precision mode must be ensured; Component compatibility must cover current and future product specifications for the next 2-3 years, including physical constraints such as feeder tray size and component height. The material handling system should be equipped with dual-track feeders and intelligent low-material warning functionality to prevent downtime losses caused by material supply interruptions. Additionally, the standardization level of the equipment maintenance module directly impacts fault response speed; prioritize models that support hot-swappable nozzle assemblies and modular calibration systems. By establishing a performance matrix scoring model for the equipment, combined with variables such as order type and product iteration cycles, a scientifically sound selection decision-making scheme can be formulated.

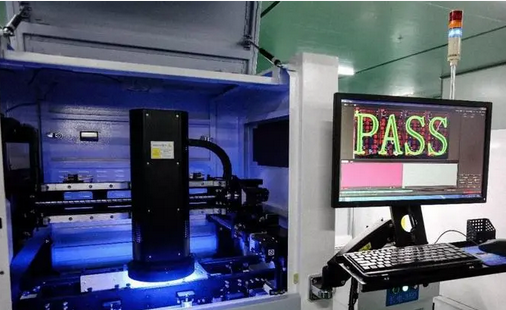

Third step is AOI inspection system deployment strategy. During the intelligent upgrade of SMT production lines, the strategic deployment of AOI inspection systems directly impacts defect detection rates and production cycle matching. Prioritize selecting equipment models with multi-spectral imaging or 3D detection capabilities based on product characteristics. For example, high-resolution optical modules should be configured for micro-components smaller than 0201. The system installation location should consider process workflow balance. Typically, an online AOI workstation is set up after reflow soldering, while offline sampling units are added at critical workstations, such as after solder paste printing. Dynamic calibration of detection parameters should be combined with the component tolerance ranges specified in the BOM list. By optimizing the combination of gray-scale thresholds and contour matching algorithms, the false positive rate can be controlled below 0.5%.

Additionally, deploying a MES data interface enables real-time feedback of inspection results and process parameters, forming a closed-loop Statistical Process Control system. Regularly conducting equipment light source decay tests and algorithm model iterations can maintain a stable detection efficiency of over 98%, providing precise data support for subsequent process adjustments.

Fourth step is reflow soldering temperature control solution. In the SMT assembly process, precise control of the reflow soldering temperature curve directly determines the quality of the solder joints and the reliability of the product. A typical temperature curve consists of four stages: preheating, constant temperature, reflow, and cooling. The peak temperature must be controlled within the range of 220–250°C and dynamically adjusted based on the characteristics of the solder paste, PCB material, and the temperature thresholds of the components. For example, when handling high-density BGA-packaged components, it is necessary to reduce the temperature rise rate (typically 1-2°C/s) to prevent solder ball collapse caused by thermal stress, while extending the time above the liquidus line (60-90 seconds) to ensure adequate solder wetting. Modern reflow soldering equipment uses multi-point thermocouples to monitor temperature zone distribution in real time, combined with closed-loop PID algorithms to achieve temperature control accuracy of ±2°C, effectively reducing defects such as cold solder joints and tombstoning. It is worth noting that temperature curve optimization must be analyzed in conjunction with the AOI inspection system. By analyzing soldering defect data, parameter adjustment directions can be determined. For example, to address bridging issues, the constant temperature time can be appropriately shortened or the peak temperature reduced. Additionally, in a nitrogen-protected environment, oxygen content must be maintained between 500-1000 ppm to suppress oxidation reactions while avoiding cost pressures from excessive nitrogen consumption.

Fifth step is key measures for controlling material loss. In the SMT assembly process, precise control of material waste directly impacts production costs and profit margins. First, the material supply system must be optimized by regularly calibrating the feeder’s feeding accuracy and using anti-static trays to keep the material loss rate below 0.3%. Second, establish a dynamic material traceability mechanism. Utilize the MES system to monitor the remaining quantity and usage frequency of material trays in real time to avoid production line downtime caused by material shortages or operational errors. For moisture-sensitive components, strictly enforce the IPC standard’s workshop environmental control measures to ensure that temperature and humidity fluctuations in storage areas remain within ±5%, while implementing the first-in, first-out principle to reduce oxidation risks. Additionally, regular maintenance of the vision calibration module on the pick-and-place machine and inspection of nozzle wear can reduce component misalignment or damage caused by decreased equipment precision. By combining the material matching algorithm of the intelligent warehouse system, companies can achieve a reduction of over 40% in material loss rates throughout the entire process from material issuance to recovery, providing a solid foundation for production capacity enhancement.

Sixth step is path to a 30% increase in production yield. To achieve breakthrough growth in SMT production line yield rates, a multi-dimensional collaborative optimization strategy must be adopted. First, through DOE experimental design, core parameters such as solder paste printing thickness and placement pressure are dynamically calibrated to ensure that the CPK value of critical processes remains stable above 1.67.

Second, we match the nozzle parameters of high-speed placement machines with component packaging characteristics to control the placement offset of 0201 components within ±0.03mm. Additionally, we establish a vibration compensation model for equipment to reduce positioning errors during high-speed operation. In the process monitoring phase, a detection system integrating 3D SPI and AOI is deployed, increasing solder joint defect detection rates from 92% to 99.5%, and a defect feature database is established to enable closed-loop optimization of process parameters. For the reflow soldering phase, segmented thermal compensation technology reduces temperature curve standard deviation by 40%, and nitrogen protection processes lower solder oxidation rates by 65%. Additionally, through an intelligent matching system between BOM lists and production line data, the material misplacement rate was reduced from 0.12% to below 0.03%. Statistical data shows that the comprehensive application of the aforementioned technical approaches can reduce defect density per unit area to below 15 dpm, providing quantifiable support for a significant improvement in yield rates.

Seventh step is strategy for doubling electronic manufacturing capacity. To double the production capacity of SMT production lines, a systematic optimization framework must be established. Through production line balancing analysis and bottleneck process identification, equipment upgrades can be prioritized for the placement process. A modular high-speed placement platform combined with a dual-track transmission system can be adopted to increase equipment utilization rates to over 92%.

Concurrently deploying an advanced production scheduling system and integrating real-time MES data enables dynamic production scheduling, reducing equipment changeover time by 40%. On the process side, a collaborative optimization mechanism for placement accuracy and reflow soldering parameters must be established. SPC statistical process control can be used to reduce the hidden losses in production capacity caused by process fluctuations. In the material supply process, an on-time supply model can be implemented in conjunction with an intelligent warehouse system to compress the material preparation cycle to within 15 minutes. It is worth noting that production line automation upgrades must be accompanied by a multi-skill training system for personnel to establish best practice models for human-machine collaboration, ensuring sustained production capacity growth.

Eighth step is which is the last step, intelligent detection and process coordination optimization. In the SMT production process, the dynamic coordination of intelligent detection technology and process parameters is a critical factor in achieving quality control and efficiency breakthroughs. Based on the high-resolution image capture and deep learning algorithms of the AOI system, the production line can real-time capture microscopic defects such as solder joint morphology and component misalignment, and analyze the distribution patterns of abnormal data through the SPC module. For example, when an increase in the rate of cold solder joints is detected in a specific area, the system can automatically adjust the pressure parameters of the pick-and-place machine or the temperature zone settings of the reflow oven, forming a closed-loop optimization mechanism.

Meanwhile, the MES integrates AOI feedback data with equipment operation logs to achieve dynamic modeling and trend prediction of process parameters, ensuring that core metrics such as placement accuracy and soldering quality remain under control. This bidirectional empowerment model between inspection and process not only shortens the traceability cycle for quality issues but also provides scientific basis for continuous optimization through data-driven decision-making pathways.

To conclude, by systematically optimizing the SMT assembly process, manufacturers can enhance efficiency across the entire production workflow. Precise control of welding parameters and strategic selection of high-speed placement equipment improve component positioning accuracy and throughput. Upgrading AOI systems with intelligent algorithms enables real-time defect detection, reducing rework costs. Meanwhile, dynamic reflow soldering temperature control—based on thermodynamic modeling—ensures solder joint reliability while shortening process tuning time. Additionally, material loss reduction and process parameter optimization contribute directly to yield improvement. Verified results demonstrate that when equipment performance, inspection accuracy, and process stability form a closed-loop system, production fault tolerance and flexibility increase, supporting the shift toward high-mix, low-volume manufacturing.