The core of AI-enabled efficient MES execution management in SMT factories lies in using artificial intelligence technology to optimize the real-time decision-making, process control, and resource scheduling capabilities of manufacturing execution systems (MES), thereby improving the efficiency, quality, and flexibility of surface mount technology (SMT) production lines. As all of our Nectec’s pick and place machines have implemented AI functionalities, there are few key points that are worth mentioning in this passage regarding improving the performance of AI-assisted SMT machines.

First key point, intelligent production scheduling and dynamic optimization. It can successfully perform real-time data-driven scheduling and bottleneck prediction and elimination. The reason behind it is because AI agents collect data such as equipment status, order priority, and material inventory in real time through MES, and use reinforcement learning (RL) or genetic algorithms to dynamically adjust production plans in response to unexpected situations such as rush orders and equipment failures, improving scheduling efficiency by more than 30%. In addition, based on historical data and real-time monitoring, AI predicts production line bottlenecks, triggers early warnings, and recommends optimization solutions.

Second key point, intelligent equipment maintenance and OEE improvement. It can seamlessly perform predictive maintenance and parameter self-optimization. The reason behind it is because we can utilize IoT data such as vibration sensors and current signals, AI models—such as the well-known LSTM neural network—can predict failures in critical components of pick-and-place machines and reflow soldering equipment, thereby reducing unplanned downtime and improving overall equipment efficiency by 15% to 25%. Not only this, AI intelligent agents automatically analyze process parameters, such as the relationship between reflow soldering temperature curves and soldering quality, which we often encounter, and dynamically adjust parameters to reduce defect rates such as cold soldering and warping.

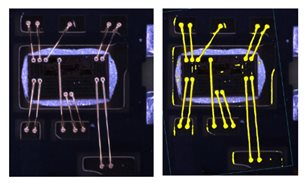

Third key point, intelligent material and warehouse management. It can simultaneously perform precise set inspection and intelligent warehouse scheduling. The reason behind it is because visual identification + RFID technology enables automatic verification of SMT trays, while AI intelligent entities provide advance warnings of material shortages in MES to avoid production line downtime. AGV/AMR and MES are linked, and AI optimizes material delivery routes based on production rhythms, improving warehouse turnover rates by 20%.

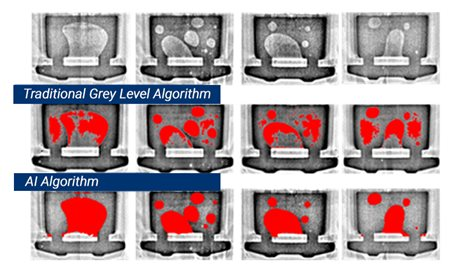

Fourth key point, quality closed-loop control. It can responsibly perform real-time defect detection and SPC intelligent analysis. The reason behind it is because data is fed back to the AI model in real time, where deep learning, such as the YOLO algorithm we all familiar with, is used to classify defect types (such as insufficient solder or misalignment) and trace them back to the process stage for automatic correction. In addition, AI replaces traditional SPC rules to identify hidden anomaly patterns in quality data (such as solder paste printing issues that drift over time) and intervene in advance.

Fifth key point, digital twins and simulation optimization. It can incredibly perform virtual production line debugging and energy consumption optimization. The reason behind it is because we can now utilize digital twin technology to simulate the SMT production process for new products, and so AI agents verify process feasibility in a virtual environment, reducing changeover time by more than 50%. AI also analyzes equipment energy consumption data to optimize the operating strategies of public facilities such as workshop air conditioning and air compressors, thereby reducing unit energy consumption.

Last key point that we want to make is human-machine collaborative decision-making. It can generously perform natural language interaction (NLP) and exception handling knowledge base. The reason behind it is because production line personnel can use voice/text to query MES data (such as work order progress) and trigger commands (such as emergency equipment shutdown) from the AI agent, reducing the time spent switching between operating interfaces. In addition, AI integrates historical maintenance records and equipment manuals to recommend solutions when faults occur, helping new employees respond quickly.

To conclude, there are some challenges that are yet to be solved in this field, we not only need to connect MES/ERP/PLM systems and build a unified data middle platform, but also use edge AI to reduce cloud load in high real-time scenarios, such as AOI inspection as we all know. We also need to display AI decision logic through visual dashboards to avoid “black box” concerns. Nevertheless, the benefits brought from solving these challenges are significant: in terms of efficiency, changeover time reduced by 40%, capacity utilization improved by 20%-35%; in terms of quality, defect rate reduced by 50%, customer complaints reduced; in terms of cost, material loss reduced by 15%, maintenance costs reduced by 30%.

At the end, thanks to the development of AI and through the deep integration of AI agents and MES, SMT factories can gradually make the leap from automation to self-automation control. As we are continuing to construct an adaptive, self-optimizing intelligent manufacturing system.