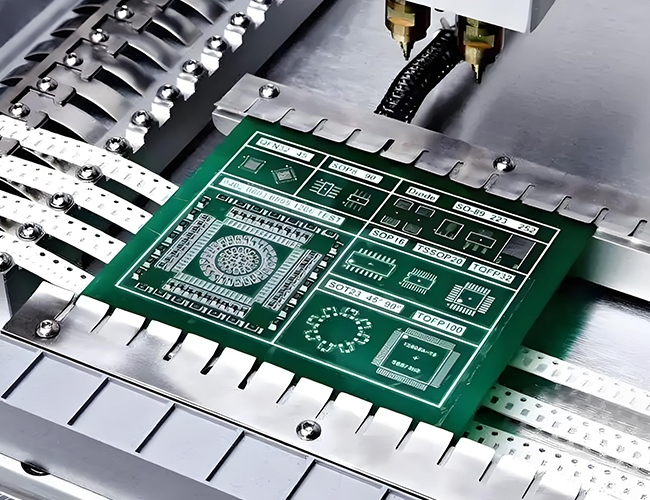

The company launched its first-generation SMT placement machine in 2008, at which time all core technical components were imported. However, after more than a decade of relentless effort and independent innovation, Nectec has now achieved domestic production of most components and systems for SMT placement machines. The company proudly states that it has independently developed and manufactured over 95% of its key components, and has successfully established itself as a national high-tech enterprise, a specialized, refined, and innovative enterprise, a well-known brand in Shenzhen, and a leading global brand in high-speed pick-and-place machine manufacturing. The four core characteristics of our Nectec’s SMT chip mounting technology include high-speed universal integration, flexible adaptation to production sites, innovative transport track system structure, and advanced software systems. Through independent innovation, Nectec has achieved localization of most components and systems of SMT placement machines, with more than 95% of key components produced independently by the company. After many years of research and development, our engineering team discovered an integrated casting process for mounting heads. This process not only ensures the mounting head is sturdy and durable, preventing deformation, but also guarantees mounting accuracy. The integrated mounting head is our patented product, and its unique design significantly improves mounting speed, accuracy, and stability. for example, NT-B5 adopts an innovative transport track system structure and advanced software system to further optimize production efficiency. Its precise cornering system allows each nozzle to independently control the angle of the components, ensuring high-precision mounting. On the other hand, high-speed flight photography and high-speed image recognition are another highlight of the NT-B5.

Nectec has deeply integrated these two technologies to achieve efficient collaboration, demonstrating its strength in technology integration. Nectec’s feeding system has undergone more than ten generations of product iterations, ultimately resulting in the successful development of a new system that combines bus control and motion control. The accuracy of the feeding system is critical to the performance of SMT placement machines, as it directly affects the precision of placement. The intelligent software system of the NT-B5 is one of its core competitive advantages. It can be customized according to customer requirements and features offline programming capabilities, effectively reducing changeover cycles. Additionally, it incorporates AI-driven intelligent learning and automatic optimization functions, and provides an MES system interface for intelligent production line management. Multiple files can be imported with a single click to set placement coordinates, and the human-machine interface is tailored to local customer needs, supporting multiple language versions, further enhancing the device’s usability and flexibility. In summary, the new domestically produced SMT placement machine launched by Nectec has not only injected new vitality into the intelligent manufacturing industry, but also provided domestic PCBA factories with more options. With continued investment by domestic manufacturers in the SMT placement machine field, we believe that more domestic equipment companies like Nectec will emerge, continuously optimizing domestic equipment and launching more products that are competitive internationally.