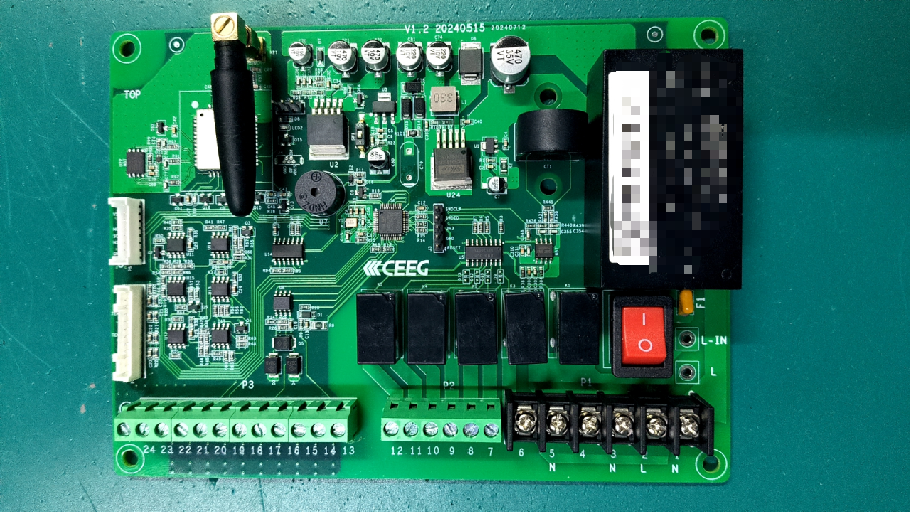

As electronic devices continue to evolve toward miniaturization and higher performance, SMT (surface mount technology) has emerged as a core process in modern electronics manufacturing. Through technological innovation, SMT is making a leap forward from “efficient production” to “intelligent manufacturing.” This article will analyze the latest developments in SMT technology from three perspectives: process flow, technological breakthroughs, and intelligent transformation. First, we would like to discuss about the conventional SMT manufacturing process: from solder paste printing to automatic inspection. To get started, SMT technology involves four core processes: solder paste printing, chip mounting, reflow soldering, and inspection. These four core processes enable high-density assembly of electronic components on PCB boards. For solder paste printing, it involves laser-cut steel mesh and high-precision printing equipment are used to ensure that the solder paste is evenly distributed on the PCB pads. Through pressure control and visual calibration technology, the solder paste thickness error can be controlled within ±5μm, laying the foundation for subsequent chip mounting. For chip mounting, it involves high-speed pick-and-place machines use suction nozzle arrays and multi-axis linkage technology to quickly pick up and accurately position components. For example, new pick-and-place machines support “flying alignment” technology, in which CCD cameras and placement heads move synchronously to perform optical calibration of components during movement, achieving placement speeds of over 100,000 times per hour. For reflow soldering, it involves through-multi-temperature zone temperature control and nitrogen protection technology, the solder paste melts under a precise heating curve and forms reliable solder joints.

Some equipment introduces laser repair technology to achieve local repair of complex components such as micro-BGA, improving yield by more than 20%. And for inspection, it involves AOI (automatic optical inspection) combined with 3D X-ray inspection systems and AI algorithms can automatically identify defects such as misalignment and cold soldering, with detection efficiency 10 times higher than traditional manual inspection. Second, we would like to discuss the technological advancement of our high precision pick and place machine. In order to meet the mounting requirements of ultra-micro components such as 01005 (0.4 mm × 0.2 mm), our pick and place machine has made significant breakthroughs in precision and stability: 1. Visual positioning accuracy ±0.01mm: Utilizing high-resolution linear encoders and a closed-loop control system, combined with multi-spectral imaging technology, it can accurately identify the position and angle of components, even when dealing with reflective or irregularly shaped parts; 2. Dynamic compensation technology: By continuously monitoring environmental changes through temperature sensors, it automatically adjusts the motion parameters of the robotic arm to eliminate errors caused by thermal expansion, ensuring stable operation over extended periods; 3. Modular design: Supports quick nozzle switching and dual-track asynchronous production, enabling the same equipment to process PCB boards of different specifications simultaneously. Line changeover time is reduced to within 5 minutes, meeting the flexible production needs of small-batch, multi-variety production.

Third, we would like to mention about how AI plays a role in the inspection and monitoring stages. Intelligence has become the core direction of SMT technology upgrades, mainly reflected in the following scenarios: 1. AI defect detection: AOI systems based on deep learning can distinguish subtle abnormalities such as solder bubble and solder ball through training with a large number of defect samples, with a misjudgment rate of less than 0.1%. For example, after introducing 3D AOI, our Nectec’s NX series increased its detection efficiency by 30% and reduced its labor costs by 40%; 2. Real-time production line monitoring: By connecting equipment such as pick-and-place machines and reflow ovens via industrial internet of things (IIoT), real-time data on temperature, pressure, and vibration is collected. Combined with big data analysis to predict equipment failures, maintenance response times are reduced by 50%; 3. Adaptive process optimization: AI algorithms automatically generate optimal placement paths and soldering parameters based on PCB material and component type, reducing idle travel and improving placement efficiency by 15%.