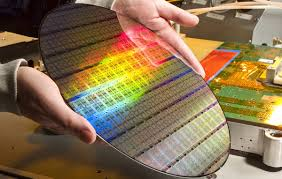

Taking Nectec’s self-developed SMT pick and place machine NT-L12 as an example, this model adopts high-speed universal integrated technology, achieving a qualitative “leap” over traditional models. The lightweight placement head of this equipment has been certified with an invention patent by a professional institution. The head is integrally molded, and all 10 Z-axis modules use modular magnetic levitation independent control, significantly enhancing the speed, precision, and stability of the placement head. Additionally, the X, Y, and Z axes all utilize high-end magnetic levitation motors, with the Y-axis employing a dual-drive gantry structure. The standard configuration of this device is 52PCS (optional dual-sided 104PCS), featuring an independent corner system that supports automatic nozzle switching functionality. The PCB board size range is from 50x50mm to 600x400mm, capable of mounting components in packages ranging from 0201 to 40x40mm (12×12 to 40x40mm requires an optional fixed camera) and IC tray components. Additionally, Nectec offers customized services, enabling the creation of equipment tailored to the specific size requirements of the customer’s business. Nectec’s latest “semiconductor IGBT chip mounting machine” is equipped with a gantry dual-drive linear motor, giving this model a powerful “heart.” At the same time, this model is also equipped with modern devices such as an automatic wafer tray loader, automatic nozzle switching structure, 3-channel alcohol spraying mechanism, automatic pin nozzle replacement mechanism, and wafer tray automatic film expansion mechanism, more efficiently meeting the automated production needs of customer enterprises. This product has been recognized by the industry as a leading domestic semiconductor IGBT placement machine. Compared to expensive overseas brands, this model is just as good, but way more affordable, making it the top choice for domestic semiconductor placement machines.