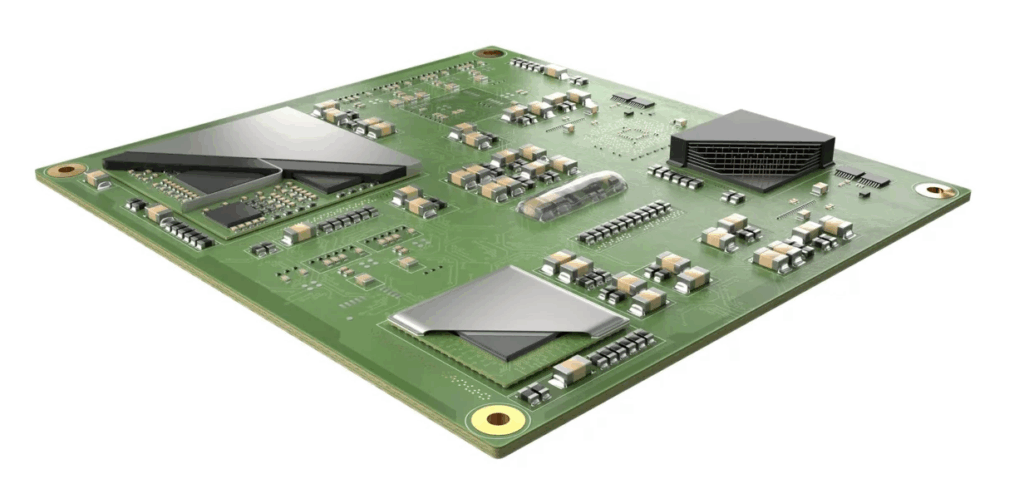

Before we get to know about the analysis of SMT core processes. We first discuss about the progression of Surface-Mount Technology (SMT) is crucial for the electronics industry and beyond. SMT allows for smaller, lighter, and more compact electronic devices by enabling the use of tiny surface-mount components (SMDs) and it is essential for wearables, smartphones, IoT devices, and medical implants. SMT components have shorter lead lengths, reducing parasitic capacitance and inductance, leading to faster signal processing and critical for high-frequency applications like 5G, AI chips, and advanced computing. Automated surface mount technology (SMT) assembly lines can increase production speed and reduce human error and can enable low-cost mass production of complex printed circuit boards (PCBs). SMDs are less prone to mechanical stress (no through-hole leads), improving longevity and are better at solder joint reliability in harsh environments (automotive, aerospace). Enables high-density interconnects (HDI) and multi-layer PCBs needed for AI, quantum computing, and advanced robotics and facilitates integration of advanced packaging techniques (e.g., 3D ICs, chiplet-based designs).

There are many aspects affecting the process, quality and outcome of the SMT manufactured chip component. Since it is a core process in modern electronics manufacturing, it is efficient to exploit the component assembly through precision equipment and process optimization. Its core process chain encompasses four key stages: solder paste printing, component placement, reflow soldering, and AOI inspection. Each step has its own purpose-precise solder deposition, component positioning, reliable solder joint formation, defect screening. Interestingly, each step also have their key variable that can directly affect the outcome of the manufacturing. Steel mesh thickness and squeegee pressure, pick-and-place machine accuracy and nozzle type, temperature zone curve and peak temperature, and optical resolution detection algorithm. They all requires rigorous compliance to process parameters and equipment precision requirements. For example, the design of the steel mesh in solder paste printing directly impacts solder joint quality, while the selection of nozzles and the precision of the placement machine in the placement process determine the accuracy of component positioning. To better understand how the analysis works, there are a total of eight steps.

Step one-overview of SMT chip mounting technology principles. SMT enables efficient assembly by directly mounting electronic components onto the surface of a PCB. Its core principle lies in abandoning traditional through-hole mounting processes, instead utilizing miniaturized components and precision equipment to achieve high-density layout. The process begins with solder paste printing, where solder paste is precisely applied to the PCB pads. Subsequently, a pick-and-place machine uses a vision positioning system to place components such as resistors and capacitors with micron-level precision at their designated positions. Finally, reflow soldering forms stable electrical connections. Compared to traditional processes, SMT offers advantages such as smaller component size, higher assembly density, and stronger automation capabilities, making it particularly suited to the lightweight and high-performance requirements of modern electronic products.

Step two-detailed explanation of solder paste printing process. First process and the quality of solder paste printing directly affects the reliability of subsequent placement and soldering. The core of this process lies in precisely transferring solder paste to the PCB pads via a steel mesh. Three key areas require attention: steel mesh fabrication, printing equipment calibration, and parameter optimization. The aperture size of the steel mesh must be designed to match the component lead spacing and pad dimensions, typically following the IPC-7525 standard. The width-to-thickness ratio of the apertures should be controlled within the range of 1.5:1 to 2:1 to ensure that the solder paste release rate meets specifications. During the printing process, the squeegee angle (45°-60°), pressure (3-8 N/cm²), and speed (20-80 mm/s) must be dynamically adjusted based on the stencil type (stainless steel/nano-coated), while SPC statistical process control is used to monitor printing offset, solder paste thickness (80-150 μm), and shape consistency in real time. For fine-pitch QFN and BGA components, a vacuum suction platform and vision positioning system are often used in conjunction to control printing accuracy within ±25 μm, preventing bridging or cold solder joint defects.

Step three-component mounting process optimization. Component placement is a critical link in the SMT production chain, and its efficiency and accuracy directly affect product yield. Process optimization should focus on three areas: equipment selection, parameter settings, and software integration: First, high-precision placement machines must be equipped with multi-axis motion systems and adaptive vision positioning modules to ensure that the placement deviation of 0201-sized components is controlled within ±0.035mm; Second, by matching the nozzle selection strategy with the vibration frequency of the feeder, the placement speed of irregular-shaped components can be increased by 15%-20%; Finally, the dynamic path planning function of the Manufacturing Execution System (MES) can reduce the idle travel of the placement head by over 30%, and when combined with a real-time pressure feedback system, it can prevent the risk of component damage. Based on this, establishing an SPC statistical process control model to analyze trends in 12 key parameters such as placement pressure and vacuum level can identify over 85% of potential process abnormalities in advance.

Step four-reflow soldering parameter control. As a core component determining solder joint quality in the SMT assembly process, reflow soldering parameters must be systematically configured based on solder paste characteristics, component types, and substrate materials. The temperature profile is a central element of process control, typically divided into four stages: preheating zone, constant temperature zone, reflow zone, and cooling zone. The preheating zone should be heated at a rate of 1.5–3°C/second to reach 150–180°C, avoiding thermal stress that could damage components; the temperature-holding zone must be maintained for 60-120 seconds to fully activate the flux and remove oxides; the peak temperature in the reflow zone must be controlled at 20-40°C above the solder paste melting point (typically 220-250°C) for 40-90 seconds to ensure adequate solder wetting; the cooling rate must be maintained at 2-4°C/second to form a dense solder joint structure. For precision components such as BGAs and QFPs, thermal simulation should be used to optimize the uniformity of hot air convection, while nitrogen protection should be employed to reduce oxidation risks. Modern reflow soldering equipment typically features multi-zone independent temperature control and real-time thermal compensation functions, combined with SPC systems for dynamic monitoring of process windows, effectively reducing the incidence of defects such as cold solder joints and incomplete solder joints.

Step five-AOI inspection technology application analysis. In the SMT assembly production process, automatic optical inspection (AOI) serves as a core component of quality control, utilizing high-precision image capture and intelligent algorithms to conduct multi-dimensional analysis of solder joint quality, component positioning, and polarity. This technology employs a combination of multi-angle lighting sources and high-speed camera systems to real-time capture typical defects such as solder paste coverage uniformity, component offset, and solder bridging, achieving detection accuracy as precise as 0.01mm. Modern AOI systems continuously optimize defect recognition capabilities through deep learning models, with false positive rates now below 2%. They also support real-time feedback of SPC data to MES systems, enabling dynamic adjustment of process parameters in a closed-loop system. In the consumer electronics sector, AOI equipment must adapt to the detection requirements of 01005 micro-components, while automotive electronics place greater emphasis on the stability of solder joint detection in high-temperature environments. With the integration of 3D detection technology and multi-spectral imaging, AOI systems are undergoing a transformative upgrade from two-dimensional planar detection to three-dimensional analysis.

Step six-Machine selection and maintenance key points. In SMT assembly processes, equipment selection must comprehensively consider production scale, product complexity, and process precision requirements. High-speed pick-and-place machines should prioritize models with multi-nozzle collaborative operation and vision-based positioning compensation capabilities to address the precise placement requirements of micro-components such as 0201 and QFN. Solder paste printing equipment should focus on stencil tension control precision and squeegee pressure adjustment range to ensure uniform solder paste deposition. When selecting a reflow oven, it is essential to evaluate the number of temperature zones, hot air circulation efficiency, and the stability of the nitrogen protection system to prevent soldering defects or component thermal damage caused by temperature curve deviations. Equipment maintenance should follow standardized procedures, including daily nozzle cleaning for placement machines, lubrication cycle management for conveyor tracks, and regular calibration of optical inspection systems. Additionally, preventive maintenance should be implemented using vibration sensors and thermal imaging cameras to minimize the impact of sudden equipment failures on production line continuity.

Step seven-analysis of quality control in key stages. In the SMT assembly production process, quality control is integrated throughout all process stages, with the core focus on reducing defect rates and ensuring product consistency through systematic measures. First, raw material inspection is a foundational step, requiring strict verification of solder paste viscosity, solder alloy composition, and component packaging specifications to ensure compliance with the IPC-A-610 standard. Second, real-time monitoring of process parameters is critical. For example, during the solder paste printing stage, squeegee pressure and stencil alignment accuracy must be dynamically adjusted via an SPC (Statistical Process Control) system to prevent misalignment or collapse. During the reflow soldering stage, the temperature curve must precisely match the solder paste characteristics and component temperature resistance. Data is collected via a furnace temperature tester to optimize heating zone parameters. AOI inspection serves as the final inspection method, using multi-spectral imaging technology to identify defects such as cold solder joints, misalignment, and polarity errors, and combining X-ray inspection for penetrating analysis of hidden solder joints in BGAs. Additionally, equipment maintenance cycle calibration and operator skill training are also critical factors in ensuring long-term stability. Through multi-dimensional data integration and a closed-loop feedback mechanism, a comprehensive quality control system is established, spanning from prevention to correction.

Step eight-application and progression of SMT industry. As electronic products continue to evolve toward miniaturization and high integration, Surface Mount Technology (SMT) has become a core manufacturing process in industries such as consumer electronics, automotive electronics, and communication equipment. In consumer products like smartphones and wearable devices, SMT technology enables efficient use of motherboard space through the placement of miniature components. In the automotive electronics sector, SMT leverages its high reliability to meet the stringent requirements of in-vehicle control systems for high-temperature resistance and vibration resistance. Currently, the widespread adoption of 5G communication base stations and IoT terminal devices is further driving the evolution of SMT processes toward ultra-high-speed placement and mixed-line production of multiple product varieties. Concurrently, the deep integration of smart manufacturing and Industry 4.0 is accelerating the adoption of advanced technologies such as AI vision inspection and digital twins on SMT production lines to achieve dynamic optimization of process parameters and defect prediction. In the future, with the expansion of emerging markets such as electric vehicle control systems and medical electronic devices, SMT technology will continue to break through in terms of material compatibility, environmentally friendly processes, and micron-level precision control, providing critical technological support for the high-quality development of the electronics manufacturing industry.