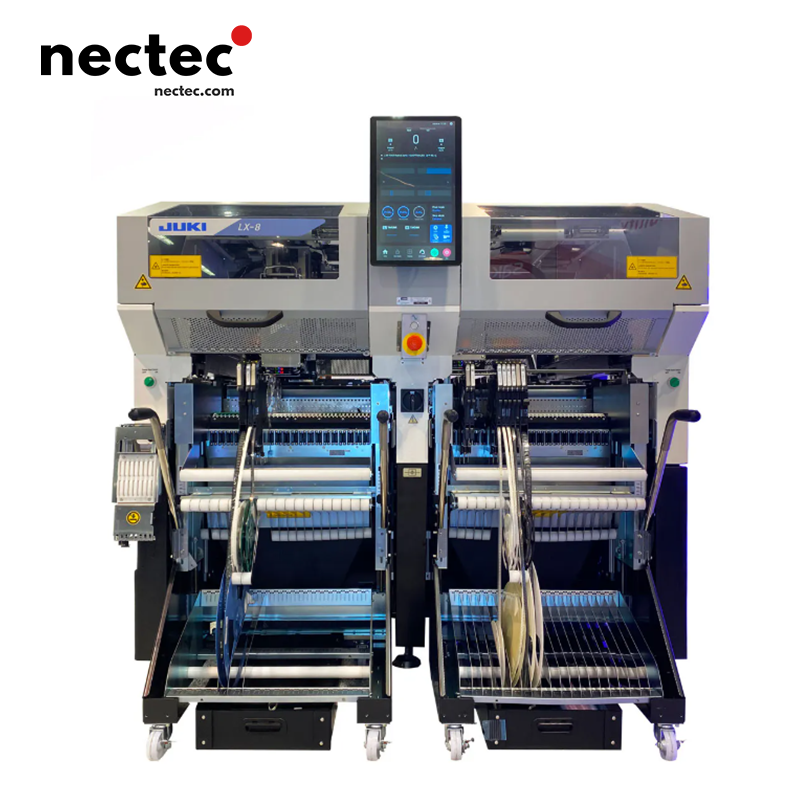

RX-6B | Snelle Compacte Modulaire Teller

De compacte RX-6R/RX-6B biedt een hoge productiviteit, flexibiliteit en kwaliteit - in een compact formaat.

Dit is van toepassing op dual-lane productie.Compacte voetafdruk: de breedte is slechts 1,25 m.Uitgerust met standaard Placement Monitor controlefunctie.Verwisselbare koppen maken het mogelijk om een productielijn te configureren die het best geschikt is voor de huidige repirments.Snelle plaatsing van componenten met behulp van high-speed non-stop vision herkenning.Breed scala aan componenten en printplaten: hoge componenten, grote componenten en grote printplaten.Gloednieuwe Matrix Tray Sever TR8S verbetert de componentcapaciteit en productiviteit.

RX-6B | Snelle Compacte Modulaire Mounter

- Beschrijving

Beschrijving

Montagekop Systeem

Architectuur voor plaatsing van meerdere spuitdoppen

- Configuraties met twee koppen: Biedt montagekoppen met 6 spuitmonden en 3 spuitmonden voor snel wisselen, waardoor gemengde plaatsing van chipcomponenten en grote IC's mogelijk is. Samenwerking tussen voorste en achterste kop vermindert bewegingsverlies, waardoor een theoretische doorvoer van 42.000 CPH (chipcomponenten) en 14.000 CPH (IC-componenten) wordt bereikt volgens de IPC-9850 normen.

- Adaptieve krachtmodulatie: 0,5N-50N dynamische drukregeling is geschikt voor gevoelige componenten (zoals LED's) en PoP (package-on-package) assemblages.

- Lasermeetsysteem (LNC): Inspecteert 0402 (01005 imperial) tot 33,5 mm vierkante componenten met een nauwkeurigheid van ±40 μm (Cpk≥1), waarbij in real-time de X/Y-positie en Z-hoogte worden gecontroleerd.

- MNVC visiemodule: Ondersteunt 3-100 mm vierkante en 50×180 mm oneven vorm componenten (bijv. lange connectoren) met ±30 μm nauwkeurigheid (hoge-resolutie camera optioneel).

Voedersysteem

Veelzijdig voederplatform

- RF-voedertechnologie: Standaard voedingsmodules met twee sporen en voeding ondersteunen 8-56 mm tape, met een capaciteit van 160 stations (8 mm tape-equivalent), compatibel met tube/tray en JEDEC-standaardcomponenten.

- Intelligent voeren: Automatische tape-splitsing en realtime waarschuwingen voor tekorten minimaliseren handmatige interventie, waardoor de continuïteit van de productie wordt verbeterd.

PCB Verwerkingssysteem

Modulaire substraatverwerking

- Mogelijkheid voor enkel/dubbel spoor:

- Enkelspoor: 50×50mm-610×590mm PCBs

- Dubbel-spoor: 50×50mm-360×250mm PCBs

- Verlenging met lange plank: Het tweetraps klemmen ondersteunt substraten tot 905×590 mm voor de productie van LED-panelen en grote printplaten.

- Gemotoriseerd ondersteuningsplatform: Vermindert transporttrillingen en verkort de klemtijd voor een betere plaatsingsstabiliteit.

Vision & Inspectiesysteem

Geavanceerde meetoplossingen

- Visie tijdens de vlucht: Componentherkenning tijdens het doorvoeren van de kop vermindert de inactiviteitstijd en optimaliseert de doorvoer.

- Pick-and-Place Verificatie: Real-time beeldvorming van pick-up en plaatsingsgebeurtenissen voorkomt de verspreiding van defecten en maakt een snelle foutdiagnose mogelijk.

- Optionele 3D-inspectie: Detecteert coplanariteit en hoogteafwijkingen van componenten om defecten door koud soldeer en tombstoning te beperken.

Motion Control Systeem

Mechanica met hoge precisie

- Lineaire motoraandrijvingen met magnetische levitatie: X/Y-assen bereiken een submicronresolutie via magnetische schalen van 0,001 mm, wat stabiliteit garandeert bij hoge snelheden.

- Y-as aandrijving met twee servo's: Optimaliseert de dynamica van de transportband om mechanische trillingen te verminderen en de herhaalbaarheid van de plaatsing te verbeteren.

Intelligente software en schaalbaarheid

JaNets Suite voor productiebeheer

- Offline programmeren: CAD import, trajectoptimalisatie en simulatie verminderen de omsteltijd via intelligente padplanning.

- Modulaire integratie: TR8S matrix tray server verbetert de verwerking van vreemde onderdelen; compatibel met de JUKI RX-7 serie voor flexibele lijnconfiguratie.

specificatie

Snelle Compacte Modulaire Mounter | ||||||

Specificaties | RX-6 | RX-6B | ||||

Grootte van het bord | enkelbaans transportband | 50X50~610X590 / 905X590mm (2times het vastklemmen) | ||||

transportband met twee banen | 50×50~360×250㎜ Enkelbaans transportband specificatiemodus max 360 × 450 mm | |||||

Hoogte component | 6/12/20/25/33mm | |||||

Componentgrootte | Laserherkenning | 0402~□50mm | 0402~□33.5mm (3 sproeikop) 0402~□50㎜(6 sproeikoppen) | |||

Gezichtsherkenning | Standaardcamera (optioneel) | □3~□33,5mm | □3~□100mm/50×180mm | |||

Hoge-resolutie camera | 1005~□20mm | 1005~□48mm/24×72mm | ||||

Plaatsingssnelheid | Chip | Optimaal bij gebruik van de enkelebaans transportbandspecificatie | 42.000CPH | 34.000CPH | ||

IPC9850 | 26.000CPH | 23.000CPH | ||||

IC*[noot] | 14.000CPH | 11.000CPH | ||||

Plaatsingsnauwkeurigheid | Laserherkenning | ±0.04mm (Cpk≧1) | ||||

Gezichtsherkenning (optioneel) | ±0,04mm | ±0,04mm | ||||

Laadhoeveelheid componenten | Max.160 in geval van 8mm tape feeder (op een elektrische dubbele tape feeder)) | |||||

Componentherkenning Camera (VCS) | Standaard | Optie | Standaard | Optie | ||

Plaatsingsmonitor Inspectiefunctie | Standaard | Optie | Standaard | Optie | ||

Automatische tapesnijder | Standaard | Optie | Standaard | Optie | ||

Mondstuk | Standaard | Optie | Standaard | Optie | ||

Krachtregeling | Standaard | Optie | Standaard | Optie | ||

Software voor virusmeting (witte lijst) | Standaard | Standaard | Standaard | Standaard | ||

De IC-notitie: De plaatsingssnelheid van IC-componenten wordt geschat bij het plaatsen van 36 stuks QFP-componenten (afmeting 10 mm in het vierkant of kleiner) op het totale M-formaat PWB, waarbij alle nozzles tegelijkertijd vanaf de voor- en achterkant worden geplukt. | ||||||