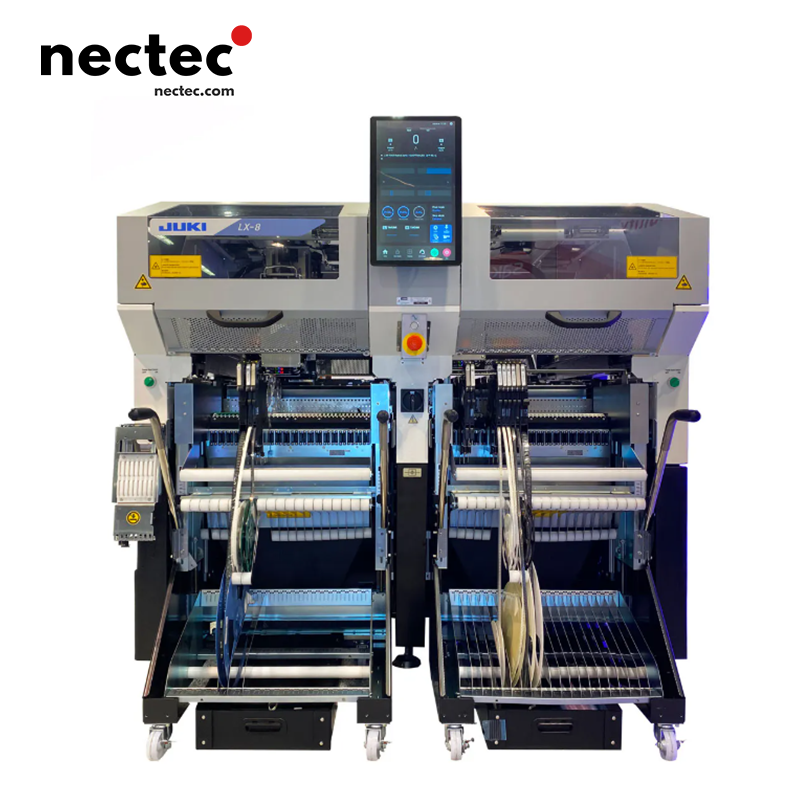

データ-trp-post-id='8614'>KE-3010A|高速モジュラー配置SMTチップシューター</trp-post-container

KE3010Aは、JUKIの第7世代モジュラー・プレースメントマシンであり、柔軟性と生産品質を向上させる最新の最先端技術です。

KE-3010A| 高速モジュール配置SMTチップシューター

- 説明

説明

レーザー認識システム(LNC60)

- 機内センタリング技術:LNC60レーザーセンサーを搭載し、ヘッド搬送中の部品の位置、角度、寸法をその場で検査可能。QFP、CSP、BGAパッケージを含む0402(01005インペリアル)~33.5mm²の部品をカバー。

- 計測性能:レーザー認識モードで±50μmの精度(Cpk≥1.0)を達成。

- リアルタイムプロセス監視:部品ピックアップから配置までの連続トラッキングにより、安定性を確保し、配置ミスのリスクを低減します。

プレースメント・ヘッド&ノズル・エンジニアリング

- 6ノズル・パラレル・アーキテクチャ:6つの独立したノズルを持つ1つの配置ヘッドは、並列ピックアンドプレースオペレーションをサポートし、理論スループット23,500CPH(チップ部品)、18,500CPH(標準ビジョン付きIC)、9,000CPH(MNVCイメージング付きIC)を達成。

- アダプティブ・フォース・モジュレーション:部品の高さ(6mm/12mm)や形状が変わっても、自動的に配置圧力を調整します。

フィーダーシステム

- EF08HD パワード・デュアル・トラック・フィーダー:160ステーション(8mm換算)の8mmテープフィーダーに対応し、従来の2倍のフィーダー密度と交換時間の短縮を実現。

- ミックスフィーダー適合性:電気式(ETF)と機械式(CTF/ATF)のフィーダーをサポートし、費用対効果の高いレガシーシステム統合を実現。

- インテリジェントなマテリアルハンドリング:スマートフィーダー技術により、テープの自動スプライシングとリアルタイムの供給不足アラートが可能になり、連続生産が可能になります。

モーション・コントロール・システム

- ハイブリッド・ドライブ技術:X/Y軸は、0.001mm分解能のリニアマグネットスケールを備えたリードスクリュードライブとフル・クローズドループ制御により、高速で低ノイズの位置決めを実現。

- デュアルサーボY軸アクチュエーション:高速運転時のコンベアの安定性を高め、振動によるエラーを最小限に抑えます。

PCB処理システム

- マルチフォーマット基板ハンドリング:

- 標準Mタイプ(330×250mm)、XLタイプ(610×560mm)

- 拡張:LEDパネルやディスプレイPCB生産用に最大1,210×560mm。

- 電動サポート・プラットフォーム:搬送振動を低減し、固定時間を短縮することで、配置の再現性を向上。

ソフトウェア&オートメーション

- Windows XPベースのHMI:直感的な多言語インターフェイス(中国語/日本語/英語)。

- JANETSオフライン・プログラミング・スイート:CADのインポート、配置パスの最適化、シミュレーションのデバッグを可能にし、生産効率を高めます。

- 統合生産モニタリング:リアルタイムのフォルトコード表示、ミスピック率追跡、内蔵データインターフェースによるMES/ERP互換性。

スペック

ボードサイズ | Mサイズ(330×250mm) | はい |

Lサイズ(410×360mm) | はい | |

Lワイドサイズ(510×360mm) (オプション) | はい | |

XLサイズ(610×560mm) | はい | |

長尺プリント配線板対応(Mサイズ) (長尺プリント配線板への対応はオプションです。) | 650×250mm | |

長尺プリント配線板対応(Lサイズ) (長尺プリント配線板への対応はオプションです。) | 800×360mm | |

長尺プリント配線板対応(Lワイドサイズ) (長尺プリント配線板への対応はオプションです。) | 1,010×360mm | |

長尺プリント配線板対応(XLサイズ) (長尺プリント配線板への対応はオプションとなります。) | 1,210×560mm | |

コンポーネントの高さ | 6mm | 12mm |

12mm | 12mm | |

コンポーネント・サイズ | レーザー認識 | 0402(01005) ~ 33.5mm |

視覚認識 | 3mm[MNVC.(オプション)使用時] ~ 33.5mm | |

1.0×0.5mm[KE-3010A:高解像度カメラとMNVCを併用する場合。(オプション) ]~ 20mm | ||

プレースメント速度 | 最適 | 23,500CPH |

IPC9850 | 18,500CPH | |

IC【有効タクト:IC搭載速度は、Mサイズ基板にQFP(100ピン以上)またはBGA(256ボール以上)を36個搭載した場合の推定値です。(CPH=1時間の部品装着数)]。 | 9,000CPH(MNVC使用時、全ノズル同時吸着時の推定値。 MNVCはKE-3010Aのオプションです) | |

プレースメントの精度 | レーザー認識 | ±0.05 mm(±3σ) |

視覚認識 | ±0.04mm | |

フィーダー入力 | 最大160(8mmテープの場合 (電気式ダブルテープフィーダーの場合)(電気式ダブルテープフィーダーEF08HD使用時。) | |