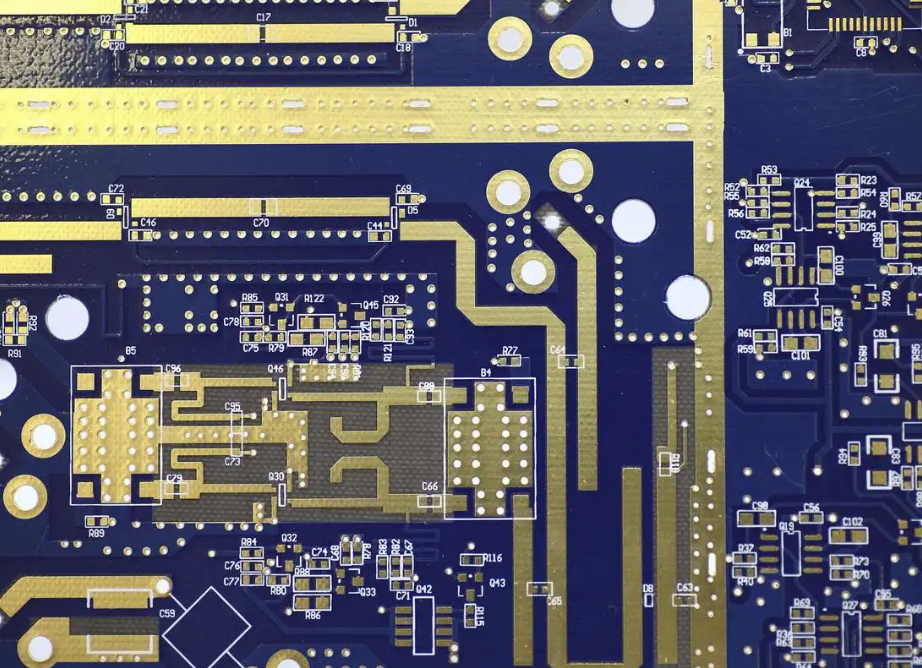

Surface Mount Technology (SMT) assembly is a core process in modern electronic manufacturing, enabling efficient and precise connection between components and printed circuit boards (PCBs) through surface mount technology, significantly enhancing product reliability and production efficiency. To begin with this chapter, we first delve into the analysis of the core techniques of SMT. Surface Mount Technology (SMT) achieves electrical connections by directly mounting electronic components on the surface of a printed circuit board (PCB). Its core principle is based on precise positioning and thermodynamic control. Unlike traditional through-hole mounting technology, SMT uses solder paste as a medium, applying solder precisely to pads via a solder paste printer, then utilizing a pick-and-place machine’s optical recognition system to achieve micron-level component positioning. During the soldering process, the reflow oven precisely controls the temperature profile, causing the solder paste to undergo four stages: preheating, constant temperature, reflow, and cooling. Our Nectec’s products are not only complete but support the entirety of the four stages mentioned above. The surface tension effect enables self-alignment and connection between the component leads and pads. The key to this technology lies in the rheological properties of solder paste, placement accuracy compensation algorithms, and thermal conductivity balance control. These elements collectively ensure the reliability of high-density, miniaturized electronic assembly, laying the foundation for quality control in subsequent process flows. Next, we discuss about the manufacturing process of the SMT technology. The SMT (Surface Mount Technology) process flow, as a core component of electronic manufacturing, typically comprises four main stages: solder paste printing, component placement, reflow soldering, and inspection

Our Nectec’s products are not only complete but support the entirety of the four stages mentioned above. The surface tension effect enables self-alignment and connection between the component leads and pads. The key to this technology lies in the rheological properties of solder paste, placement accuracy compensation algorithms, and thermal conductivity balance control. These elements collectively ensure the reliability of high-density, miniaturized electronic assembly, laying the foundation for quality control in subsequent process flows. Next, we discuss about the manufacturing process of the SMT technology. The SMT (Surface Mount Technology) process flow, as a core component of electronic manufacturing, typically comprises four main stages: solder paste printing, component placement, reflow soldering, and inspection.

First, high-precision screen printing machines uniformly apply solder paste to the PCB pads. Subsequently, a vision positioning system is used to precisely place components, with pick-and-place machines picking up components via nozzles and placing them at high speed according to pre-set coordinates. During the reflow soldering stage, the PCB board is heated according to a temperature control curve to melt the solder paste and form reliable solder joints. The temperature gradient control in the preheating zone, constant temperature zone, reflow zone, and cooling zone directly impacts soldering quality. At the end of the process, Our Nectec’s NX-B battery inspection machine acts as one of the example for showing its excellence AOI function to perform a full inspection of solder joint morphology and component misalignment defects. Some production lines also combine X-ray inspection to detect hidden solder joints such as BGAs. With the penetration of smart manufacturing technology, MES systems are connected to equipment to enable real-time monitoring of process parameters, further improving production yield and process stability. Then, we would like to discuss some of the key points for controlling reflow soldering parameters. In SMT assembly, the process parameters of the reflow soldering stage directly impact soldering quality and product reliability. The temperature curve, as a core control element, must be precisely divided into preheating, constant temperature, reflow, and cooling zones. Thanks to our Nectec’s RO-8840 reflow solder machine, it supports an affluent amount of space for chip components to safely go through these zones. The temperature gradients and time windows for each stage must be dynamically adjusted based on the PCB substrate material, solder paste characteristics, and component temperature limits.

During the preheating stage, rapid temperature increases that could lead to thermal stress accumulation must be avoided, typically controlled at 1.5–3°C/s. The constant temperature zone must ensure that the flux is fully activated and oxides are removed; excessive dwell time may cause solder oxidation. The peak temperature in the reflow zone must be 20–30°C above the solder paste melting point, but risks of component thermal damage must be avoided. Additionally, the coordinated control of chain speed, nitrogen concentration, and hot air convection intensity can significantly reduce solder joint voids and poor wetting. By monitoring the furnace temperature curve in real time and analyzing SPC data, a closed-loop feedback mechanism can be established to ensure parameter stability and process consistency. Last but not least, SMT technology is advancing fast. With the deep integration of Industry 4.0 and smart manufacturing, SMT assembly is accelerating its evolution toward digitalization and flexibility. Through industrial Internet of Things (IIoT) and big data analysis technologies, production lines achieve real-time collection and dynamic optimization of equipment status, process parameters, and material information. For example, defect prediction models based on AI algorithms can identify welding misalignment or component polarity errors in advance, significantly reducing rework rates. The introduction of digital twin technology has broken through physical limitations in process simulation and parameter optimization. Especially in high-density assembly scenarios involving 01005 micro-components or flip-chip technology, virtual debugging can be used to quickly validate production plans. The collaborative application of collaborative robots (Cobots) and intelligent vision systems not only improves the accuracy of AOI inspection but also achieves integrated closed-loop management of automatic material tray replacement and anomaly response.

Additionally, flexible manufacturing systems (FMS) accommodate diverse product varieties and small-batch production demands through modular design, providing agile support for consumer electronics iteration and automotive electronics customization needs. The integration of 5G communication and edge computing further ensures millisecond-level real-time feedback for high-precision pick-and-place machine motion control and temperature curves, driving continuous breakthroughs in SMT processing toward intelligent and sustainable directions