Made in China 2025'in ilerlemesiyle birlikte, akıllı üretim giderek geleneksel endüstrilerin dönüşümü ve iyileştirilmesi için temel yön haline gelmiştir. Akıllı üretim sisteminde, online X-ray kontrol cihazı vazgeçilmez bir rol oynamaktadır. Elektronik üretimi ve otomotiv endüstrisinden yeni enerji ve tıbbi cihazlara kadar, bu tür ekipmanlar akıllı üretim hatlarına derinlemesine entegre edilmiş ve kalite kontrol için önemli bir araç haline gelmiştir. Peki, X-ray kontrol ekipmanı akıllı üretim için neden vazgeçilmezdir? Bu soruyu çeşitli açılardan kapsamlı bir şekilde analiz edeceğiz.

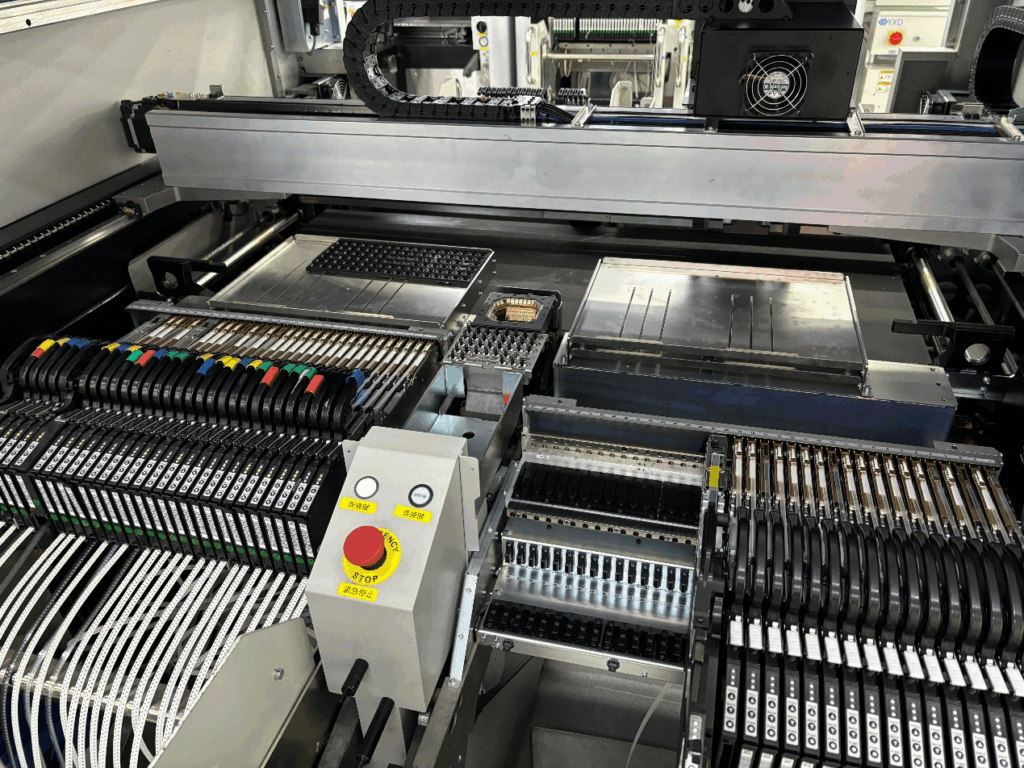

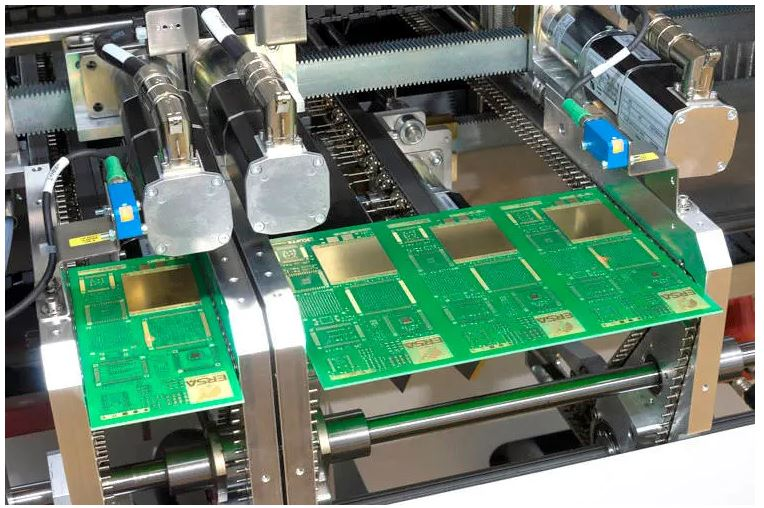

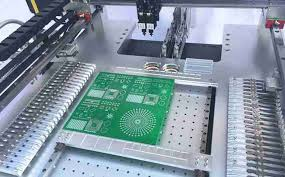

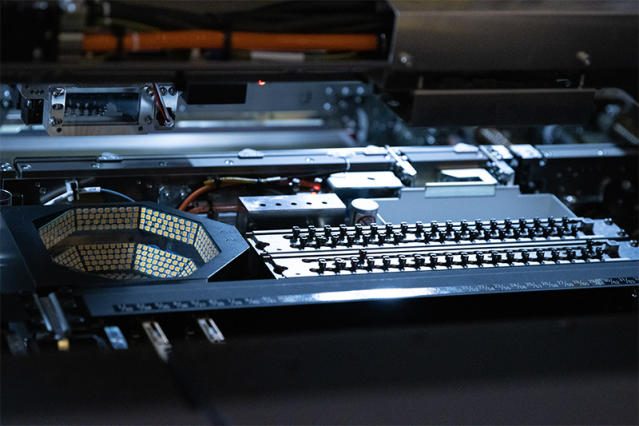

İlk olarak, online X-ray kontrol cihazı nedir? Online X-ray kontrol ekipmanı, ürünler üzerinde kayıpsız test gerçekleştirmek için X ışınlarını kullanan cihazları ifade eder. Bu cihazlar otomatik üretim hatlarına entegre edilerek gerçek zamanlı, sürekli ve yüksek hassasiyetli kontrol yapılmasını sağlar. Nesnelerin iç yapısına nüfuz ederek kusurlar, çatlaklar ve kaynak kalitesi gibi "görünmez sorunları" görsel olarak ortaya çıkarırlar. Genellikle PCB lehim bağlantıları, lityum-iyon pil ambalajları, motor sargıları ve alüminyum döküm parçalar gibi yüksek hassasiyetli bileşenleri denetlemek için kullanılırlar. Geleneksel çevrimdışı denetimin aksine, çevrimiçi sistemler gerçek zamanlı olarak veri toplayabilir ve anomali geri bildirimi ve otomatik düzeltme sağlamak için üretim yürütme sistemleriyle entegre olabilir, böylece ürün tutarlılığını artırır, yanıt sürelerini azaltır ve insan müdahalesini en aza indirir.

İkinci olarak, geleneksel kalite denetim yöntemlerinin bazı sınırlamalarını tartışmak istiyoruz. Geçmişte, imalat endüstrisi genellikle manuel numune alma veya görsel denetime dayanıyordu, ancak bu yöntemlerin bariz eksiklikleri var. İlk eksiklik, örneklemenin ürün kalitesini kapsamlı bir şekilde değerlendirememesidir. Özellikle seri üretimde, yalnızca örneklemeye güvenmek kritik kusurları gözden kaçırabilir. İkinci eksiklik ise yüksek insan hatasıdır. Bunun nedeni, farklı operatörlerin tutarsız standartlara sahip olması ve öznel yargıların kolayca tutarsızlıklara yol açabilmesidir. Üçüncü sınırlama ise tespitte yaşanan güçlü gecikmedir. Bunun nedeni, sorunların genellikle ancak çok sayıda kusurlu ürün üretildikten sonra tespit edilmesi ve bunun da kaynak israfına ve yeniden çalışmaya yol açmasıdır. Hassas üretim ve büyük ölçekli otomasyon bağlamında, geleneksel yöntemler artık yüksek kaliteli, yüksek verimli üretim taleplerini karşılamak için yeterli değildir.

Üçüncü olarak, bazen insanlar X-ray kontrolünün akıllı üretim için neden daha uygun olduğunu merak eder. Bunun altında yatan sebep, akıllı üretimin vurguladığı kapalı döngü algılama, karar verme ve uygulama sistemidir. Algılama aşamasının temel bileşenlerinden biri olan X-ray kontrolü birkaç önemli avantaj sunar. İlk olarak, temassız ve tahribatsız testlere olanak tanıyarak ürünlerdeki kusurların sökülmeden tespit edilmesini sağlar ve böylece kontrol proseslerinin neden olduğu ikincil hasarları önler. İkinci olarak, yüksek verim ve düşük hata oranlarına ulaşır. Bunun nedeni, denetim makinelerinin otomatik yükleme/boşaltma ve akıllı görüntü tanıma yapabilmesi ve bu sayede manuel denetimin çok ötesinde bir doğruluk elde edebilmesidir. Üçüncü olarak, veri odaklı kalite yönetimini mümkün kılar. X-ray görüntüleri, kusur eğilimi analizi ve ekipman izleme için büyük veri platformlarıyla entegre edilebilir.

Dördüncü olarak, kapalı döngü üretim kontrolünü destekler. Denetim sonuçları, parametrelerin kendi kendine ayarlanmasını, süreç optimizasyonunu ve kendi kendine öğrenen bir sistemin oluşturulmasını sağlamak için üretim hattına geri beslenebilir. Bu yetenekler akıllı üretimin temel hedefleriyle uyumludur: yüksek istikrar, tutarlılık ve yanıt verebilirlik.

Dördüncü olarak‘Hepimizin aşina olduğu geleneksel SMT endüstrisinin dışında X-ray kontrolünün bazı gerçek hayat uygulama senaryolarını kısaca tartışalım. İlk senaryo yeni enerji sektörüdür: Bu sektörde lityum pil elektrot katmanları, lehim bağlantıları ve iç kabarcıklar kontrol edilerek pil güvenliği artırılır; İkinci senaryo otomotiv sektörüdür: Bu sektörde alüminyum döküm parçalardaki yapısal çatlaklar kayıpsız test edilerek tüm aracın yapısal sağlamlığı sağlanır; Üçüncü senaryo yarı iletken ambalajlama sektörüdür: yaptığı şey, dahili çip bağlantılarının ve flip chip kusurlarının hassas denetimini kullanmaktır; Dördüncü senaryo tıbbi cihazlardır: yaptığı şey, kardiyak stentlerin ve implantların iç bütünlüğünün tam denetim kontrolünü gerçekleştirmektir; Beşinci ve son senaryo son derece güvenilir elektronik ürünlerdir: bu senaryo genellikle havacılık ve uzay elektronik modüllerinin tam çevrimiçi testini içerir. Bu uygulamaların ortak bir yönü vardır: sıfır hata ve son derece yüksek proses kontrol standartları gerektirirler. Nectec olarak, yüksek hassasiyetli, son teknoloji X-ray kontrol cihazlarımızın X-ray kontrol teknolojimizin müşterilerimizin kalite güvence proseslerinin önemli bir parçası haline gelmesini sağlayacağından eminiz.

Beşinci olarak, bu tür X-ray kontrol tekniklerinin gelecekteki teknolojik beklentileri ve gelişim yönleri hakkında bazı bilgiler vermek istiyoruz. İlk kilit nokta çözünürlük ve penetrasyonda ikili iyileştirmedir: bunun nedeni, yüksek çözünürlüklü dedektörlerle birleştirilmiş yüksek enerjili X ışınlarının daha geniş bir malzeme ve boyut yelpazesini kapsayabilmesidir; İkinci kilit nokta AI akıllı tanımadır: bunun nedeni, karmaşık kusur türlerini tanımlamak için derin öğrenme algoritmaları kullanması, yanlış pozitifleri ve yanlış negatifleri azaltmasıdır; Üçüncü kilit nokta çok boyutlu füzyon algılamadır: Bunun nedeni, yapısal tanıma yeteneklerini geliştirmek için CT tomografi, 3D rekonstrüksiyon ve diğer teknolojileri birleştirmesidir; Dördüncü kilit nokta, endüstriyel İnternet ile entegrasyondur: Bunun nedeni, bulut platformuna beslenen, uzaktan çalıştırma ve bakımı, veri görselleştirmeyi ve kalite izlenebilirliğini destekleyen denetim sonuçları sağlamasıdır.

Sonuç olarak, günümüzün akıllı, esnek ve dijital üretim dünyasında online X-ray kontrolü artık bir seçenek değil, yüksek kaliteli üretim ve sürdürülebilir kalkınma için bir gerekliliktir. Yalnızca kontrol verimliliğini ve doğruluğunu iyileştirmekle kalmaz, aynı zamanda işletmelerin uçtan uca kalite kontrol yetenekleri oluşturmasına yardımcı olarak endüstriyel zincir yükseltmelerini teşvik eder. Bu nedenle, ister geleneksel fabrikaların akıllı dönüşümü ister yeni dijital üretim hatlarının inşası olsun, X-ray kontrolü vazgeçilmez bir altyapı haline gelmektedir.

Gelecekte X-ray yalnızca bir algılama aracı olmakla kalmayacak, aynı zamanda akıllı fabrikalar için bir veri kaynağı ve geri bildirim merkezi olarak hizmet verecek ve tüm üretim karar verme sürecine katılacaktır. X-ray'in yaygın olarak benimsenmesi ve evrimi, daha fazla şeffaflık, verimlilik ve güvenilirlikle karakterize edilen yeni bir üretim çağının gelişini müjdeliyor.