Akıllı SMT (Yüzey Montaj Teknolojisi) mounter, modern elektronik üretimindeki temel ekipmanlardan biridir ve PCB (Baskılı Devre Kartı) üzerine bileşen montajında yaygın olarak kullanılmaktadır. Endüstri 4.0, yapay zeka, Nesnelerin İnterneti ve diğer teknolojilerin hızla gelişmesiyle birlikte, akıllı SMT montaj makineleri de üretim verimliliğini, doğruluğunu ve esnekliğini artırmak için sürekli olarak yeni teknolojiler sunmaktadır. Nectec ekibimiz, gelecekteki potansiyel müşterilerimizin SMT yüksek teknoloji ekipmanlarımızı seçmelerine daha doğru bir şekilde yardımcı olmak için akıllı SMT montaj makinelerindeki bazı yeni teknoloji uygulamalarının SMT endüstrisine sağladığı faydaları ve geliştirme eğilimlerini analiz edecektir.

Tartışmak istediğimiz ilk uygulama bilgisayarla görme ve yapay zekadır. Bilgisayar görüşü, akıllı SMT montaj makinelerinin temel teknolojilerinden biridir. Bileşenleri, PCB kartlarını ve montaj konumlarını doğru bir şekilde tanımlamak ve bulmak için yüksek çözünürlüklü kameralar ve görüntü işleme algoritmaları kullanır. Son yıllarda, yapay zeka teknolojisinin tanıtılması, bilgisayarla görmenin yeteneklerini daha da geliştirmiştir. Teknolojisinin temsil ettiği iki temel teknoloji köşe taşı vardır. Birincisi derin öğrenme algoritmasıdır: Derin öğrenme algoritması sayesinde akıllı SMT mounter, bileşenler karmaşık şekillerde olsa veya işaretlenmemiş olsa bile farklı bileşen türlerini otomatik olarak tanımlayabilir ve sınıflandırabilir. Net olması durumunda, yüksek hassasiyetli tanımlama da elde edilebilir. Ayrıca yapay zeka, montaj yolunu optimize etmek ve montaj süresini azaltmak için geçmiş verileri de analiz edebilir; ikincisi ise kusur tespitidir: AI teknolojisi, montajcının montaj işlemi sırasında bileşenlerin yanlış yerleştirilmesi, eksik olması veya hasar görmesi gibi kusurları gerçek zamanlı olarak tespit etmesine yardımcı olabilir. Makine öğrenimi sayesinde sistem, algılama algoritmalarını sürekli olarak optimize edebilir ve kusur tespitinin doğruluğunu ve verimliliğini artırabilir.

Tartışmak istediğimiz ikinci uygulama ise yüksek hassasiyetli hareket kontrolüdür. Mounter'ın yerleştirme doğruluğu PCB kartının kalitesini doğrudan etkiler. Elektronik bileşenler giderek daha minyatür hale geldikçe, montaj makinelerinin hareket kontrolüne yönelik gereksinimler de giderek artmaktadır. Bu kontrol sisteminin iki temsili teknik köşe taşı vardır. Bunlardan ilki lineer motorlar ve servo sistemlerdir: Modern akıllı SMT montaj makineleri genellikle nano-hassasiyette hareket kontrolü sağlayabilen lineer motorlar ve yüksek performanslı servo sistemler kullanır. Lineer motorlar, özellikle yüksek hızlı ve yüksek hassasiyetli montaj gereksinimleri için uygun olan hızlı tepki hızı ve yüksek konumlandırma hassasiyeti özelliklerine sahiptir; ikincisi çok eksenli bağlantı kontrolüdür: montajcıların genellikle X, Y, Z ekseni ve dönüş ekseni gibi birden fazla hareket eksenini aynı anda kontrol etmesi gerekir. Çok eksenli bağlantı kontrol teknolojisi sayesinde, montaj makinesi karmaşık montaj eylemlerini gerçekleştirebilir ve montaj verimliliğini ve doğruluğunu artırabilir.

Tartışmak istediğimiz üçüncü uygulama IoT ve büyük veri analizidir. Nesnelerin İnterneti teknolojisinin tanıtılması, akıllı SMT montaj cihazlarının veri paylaşımı ve işbirliğine dayalı çalışma elde etmek için diğer üretim ekipmanları ve yönetim sistemleriyle sorunsuz bir şekilde bağlantı kurmasını sağlar. Bu özel teknolojinin iki temel işlevi vardır. Birincisi gerçek zamanlı izleme ve uzaktan kontroldür: Nesnelerin İnterneti teknolojisi sayesinde, yöneticilerin uzaktan izlemesi ve analiz etmesi için montaj makinesinin çalışma durumu, montaj verileri, arıza bilgileri vb. gerçek zamanlı olarak buluta yüklenebilir.

Ekipmanda bir anormallik meydana geldiğinde, sistem otomatik olarak alarm verebilir ve hatta arızaları uzaktan teşhis edip onarabilir; ikincisi büyük veri analizidir: montaj makinesi çalışma sırasında montaj hızı, doğruluğu ve bileşen kullanımı gibi büyük miktarda veri üretecektir. durum vb. Büyük veri analizi sayesinde şirketler üretim süreçlerini optimize edebilir, ekipman arızalarını öngörebilir ve üretim maliyetlerini azaltabilir. Gerçek bir örnek vermek gerekirse, Nectec'in eski müşterileri montaj verilerini analiz etti ve bazı bileşenlerin montaj başarı oranının düşük olduğunu tespit etti. Daha sonra montaj parametrelerini ayarladılar ve bileşenleri ihtiyaçlara göre zamanında değiştirdiler.

Tartışmak istediğimiz dördüncü uygulama esnek üretim ve modüler tasarımdır. Çeşitlendirilmiş elektronik ürünlere olan talebin artmasıyla birlikte, akıllı SMT (Yüzey Montaj Teknolojisi) alma ve yerleştirme makinelerinin farklı ürünlerin üretim ihtiyaçlarını karşılamak için daha yüksek esneklik sergilemesi gerekmektedir. Bu esneklik iki açıdan ortaya çıkmaktadır. İlk husus modüler tasarımdır: modern al ve yerleştir makineleri tipik olarak modüler bir tasarıma sahiptir ve müşterilerin yüksek hızlı montaj kafaları, yüksek hassasiyetli montaj kafaları, dağıtım modülleri vb. gibi farklı işlevsel modülleri üretim ihtiyaçlarına göre esnek bir şekilde yapılandırmasına olanak tanır. Bu tasarım sadece ekipmanın esnekliğini arttırmakla kalmaz, aynı zamanda bakım maliyetlerini de azaltır. İkinci husus hızlı değiştirme teknolojisidir: çoklu çeşitlerin ve küçük partilerin üretim modeline uyum sağlamak için, akıllı SMT alma ve yerleştirme makineleri hızlı değiştirme teknolojisini tanıtmıştır. Emme nozullarını otomatik olarak değiştirerek ve montaj parametrelerini ayarlayarak, alma ve yerleştirme makineleri farklı ürünlere geçişi kısa sürede tamamlayabilir ve arıza süresini azaltabilir.

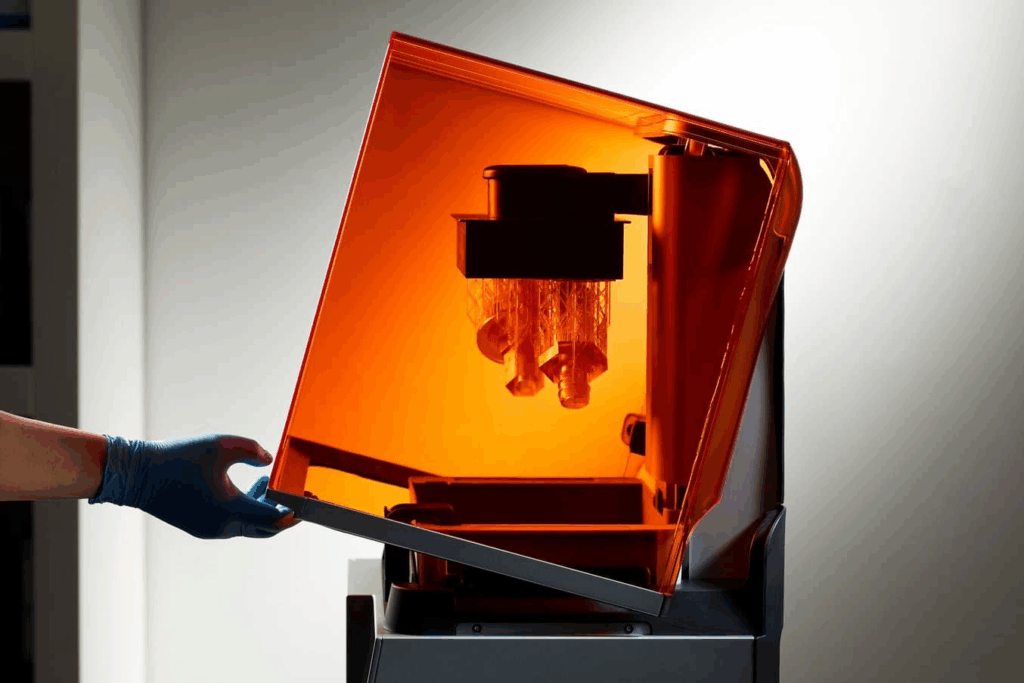

Tartışmak istediğimiz beşinci uygulama 3D baskı ve katkılı üretimdir. 3D baskı teknolojisi öncelikle prototipleme ve düşük hacimli üretim için kullanılsa da, SMT (Yüzey Montaj Teknolojisi) alma ve yerleştirme makineleri alanında da bir etki yaratmaya başlıyor. Nectec araştırma ekibi SMT alanında 3D baskı teknolojisinin iki uygulamasını tespit etti. Bunlardan ilki özelleştirilmiş emme nozulları ve fikstürleri: SMT üreticileri, 3D baskı teknolojisini kullanarak benzersiz şekil veya boyutlardaki bileşenleri barındıran özelleştirilmiş emme nozulları ve fikstürleri hızlı bir şekilde üretebilir. Bu yaklaşım sadece üretim döngüsünü kısaltmakla kalmaz, aynı zamanda maliyetleri de düşürür. İkinci uygulama ise onarımlar için katmanlı üretimdir: Alma ve yerleştirme makinelerindeki hassas bileşenler uzun süreli kullanımda aşınma veya hasara uğrayabilir. Eklemeli üretim teknolojisiyle, bileşenin tamamı değiştirilmeden yerel onarımlar yapılabilir ve böylece ekipmanın ömrü uzatılabilir.

Tartışmak istediğimiz altıncı uygulama yeşil üretim ve enerji tasarrufu teknolojisidir. Çevre koruma bilincinin artmasıyla birlikte, akıllı SMT yüzey montaj makineleri yavaş yavaş yeşil üretim ve enerji tasarrufu teknolojilerini tanıtmaktadır. İlk enerji tasarrufu teknolojisi, enerji tasarruflu motorlar ve sürücülerdir: modern yüzey montaj makineleri, optimize edilmiş kontrol algoritmaları aracılığıyla enerji tüketimini azaltmak için genellikle enerji tasarruflu motorlar ve sürücüler kullanır. Örneğin, SMT makinesi boşta kaldığında, sistem güç tüketimini azaltmak için motor hızını otomatik olarak düşürebilir veya bekleme moduna girebilir; İkinci enerji tasarrufu teknolojisi, çevre dostu malzeme ve süreçlerin kullanılmasıdır: Yüzey montaj makinelerinin üretim sürecinde, giderek daha fazla şirket çevre üzerindeki etkilerini azaltmak için kurşunsuz lehim, düşük uçucu organik bileşik (VOC) kaplamalar vb. gibi çevre dostu malzemeler ve süreçler kullanmaya başlıyor.

Tartışmak istediğimiz yedinci uygulama artırılmış gerçeklik (AR) ve sanal gerçekliktir (VR). Artırılmış gerçeklik ve sanal gerçeklik teknolojileri, akıllı SMT yüzey montaj makinelerinin çalıştırılması ve bakımına kademeli olarak uygulanmaktadır. İlk olarak, AR destekli operasyon genellikle operatörlerin yüzey montaj makinesinin gerçek çalışma ortamında sanal operasyon istemlerini ve arıza teşhis bilgilerini görebildiği ve böylece operasyonun doğruluğunu ve verimliliğini artırdığı AR gözlükleri veya tablet cihazları aracılığıyla gerçekleştirilir. Daha sonra, VR eğitimi ve simülasyonu genellikle VR teknolojisi aracılığıyla gerçekleştirilir. İşletmeler, yeni çalışanlar için sanal SMT makine operasyon eğitimi sağlayabilir, böylece sanal bir ortamda ekipmanın çalışmasına ve arıza işlemeye aşina olabilirler ve gerçek operasyondaki hataları azaltabilirler. Bu iki teknoloji benzer olsa da, kullanılan gerçek teknikler ve çalışanlara sağlayabilecekleri öğrenme bilgisi ve deneyimi tamamen farklıdır.

Sonuç olarak, modern elektronik üretimin temel ekipmanı olan akıllı SMT yüzey montaj makineleri, üretim verimliliğini, doğruluğunu ve esnekliğini artırmak için sürekli olarak yeni teknolojiler sunmaktadır. Makine görüşü ve yapay zeka, yüksek hassasiyetli hareket kontrolü, Nesnelerin İnterneti ve büyük veri analizi, esnek üretim ve modüler tasarım, 3D baskı ve eklemeli üretim, yeşil üretim ve enerji tasarrufu teknolojisi, artırılmış gerçeklik ve sanal gerçeklik ve diğer teknolojilerin uygulanması, akıllı SMT yüzey montaj makinelerinin elektronik ürünlerin çeşitlendirilmiş ve minyatürleştirilmiş üretim ihtiyaçlarına daha iyi uyum sağlamasına olanak tanıyarak elektronik üretim endüstrisinin zeka ve yeşil yöne doğru gelişimini teşvik etmektedir.

Gelecekte, teknolojinin sürekli ilerlemesiyle birlikte, akıllı SMT yüzey montaj makineleri elektronik üretim alanında önemli bir rol oynamaya devam edecektir.