NI-H20 | Super Series Radial Component Insert Machine

The NI-H20 Super Series Radial Component Insert Machine, belonging to the M, H, and K series of component insertion machines, is one of the core pieces of equipment in the through-hole mounting process of the electronics manufacturing industry. Its core purpose is to solve the efficiency balance problem between upstream and downstream processes on the production line, adapting to surface mount technology (SMT) production lines and various electronic component insertion needs. It is particularly suitable for mass production scenarios with high requirements for insertion speed, accuracy, and stability, such as PCB insertion production for power supplies, small household appliances, and automotive electronics.

NI-H20 | Super Series Radial Component Insert Machine

- Popis

Popis

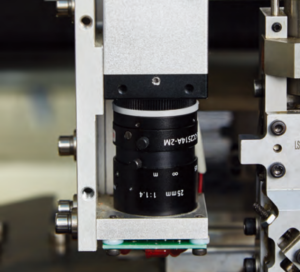

High Precision Fixed Vision System Extraordinary Accuracy Deviation Correction Ability. PCB manufacturing deviation is a common phenomenon that p r with high-precision fixed camera vision system,which can correct PCB manufacturing deviation in real time and effectively improve the yield of insertion process. The welldesigned ixed position of the camera ensures the ield of view to the greatest extent and effectively covers the operation range of PC insertion with the largest size.

High Productivity Faster Speed. With the actual insertion speed(UPH)of0.22seconds/ piece (up to the best state) for RH series and 0.26 seconds/ piece (up to the best state) for MR series,it is easy to raise the balance of pracess eficiency before and after the production line to a new level. Its best performance of 300ppm (up to)insertion defect rate is to improve the equipment utllization rate and system productivity to an unprecedented level.

Friendly Dual Operation Interface Distribution More Convenient Operability. Thanks to the friendly intelligent sottware operating system HR/MR series is equipped with front and rear dual operation interaces and operation handles. Multi core processing supports enhanced touch screen graphical user interface, which brings the ultimate user experience. You can also select human-machine communication module accarding to the needs of process management to realize a more intelligent equipment management system.

špecifikácia

Položka | NI-H20 | NI-R20 | |

Theoretical Speed | Approx 28,000 CPH | Approx 20,000 CPH | |

Insertion Direction | 0��-360��, 1�� Increment | 0��-360��, 1�� Increment | |

Lead Span | 2.5mm/5.0mm;2.5mm/5.0mm/7.5mm; 5.0mm/7.5mm/10.0mm;2.5mm/3.5mm/5.0mm; 2.5mm/5.0mm/7.5mm/10.0mm; 10.0/12.5/15.0mm. Selectable | 2.5mm/5.0mm;2.5mm/5.0mm/7.5mm; 5.0mm/7.5mm/10.0mm;2.5mm/5.0mm/7.5mm/10.0mm; 10.0/12.5/15.0mm. Selectable | |

Veľkosť dosky | Min 50mm*50mm Max 400mm*350mm | Min 50mm*50mm Max 400mm*350mm | |

Process Height | 900+20mm | 900+20mm | |

Hrúbka dosky | 0.79~2.36mm | 0.79~2.36mm | |

Component parameter | Max 23mm(26mm option);13mm;Height max 23mm (26mm option); Diameter within 13mm | Max 23mm(26mm);13mm;Height max 23mm (26mm option); Diameter within 13mm | Ԫ�����Max 23mm(��ѡ26mm);Ԫ��ֱ��13mm֮��;Height max 23mm (26mm option); Diameter within 13mm

����,�����,������,LED ��,��������,����,������,��Ȧ,��λ��,����˿��,�۶�˿����ʽƫ����װ��

Capacitor, Transistor, Triode, LED Mini Switch, Resi

stor, Connector, Coil, Potentiometer, Fuse Block, Other

Radial style taped components. |

Component Style | Capacitor, Transistor, Triode, LED, Mini Switch, Resistor, Connector, Coil, Potentiometer, Fuse Block, Other

Radial style taped components | Capacitor, Transistor, Triode, LED, Mini Switch, Resistor, Connector, Coil, Potentiometer, Fuse Block, Other

Radial style taped components | |

Cut & Clinch Length | 1.2/1.5/1.8mm (Selectable ) | 1.2/1.5/1.8mm (Selectable ) | |

Clinch Angle | 25��~45�� External Bending ; 3.5mm Lead Span Internal/External Bending Selectable 3.5mm / | 25��~45�� External Bending ; 3.5mm Lead Span Internal/External Bending Selectable 3.5mm / | |

Component Stations | 20 STD ( 10,30,40,60,80,100 Option ) | 20 STD ( 30,40,60,80,100 Option ) | |

Machine Dimension | Main Body : L1950xW1650xH1700mm | Main Body : L1950xW1650xH1700mm | |

Component Station Size | L1800xW1450xH1100 mm | L1800xW1450xH1100 mm | |

Hmotnosť | Main Body ; Approx 1200kg | Main Body ; Approx 1200kg | |

Požiadavky na napájanie | AC220V, Single Phase, 50/60Hz, 1.5Kw | AC220V, Single Phase, 50/60Hz, 1.5Kw | |

Power Protection | UPS ()15 minutes duration after power cut-off ( Option ) | UPS ()15 minutes duration after power cut-off ( Option ) | |

Tlak vzduchu | 0.6 Mpa | 0.6 Mpa | |

Air Consumption | 0.3 M3/min | 0.3 M3/min | |

Environmental Temperature | 20�� �� 10�� | 20�� �� 10�� | |

Noise Level | Approx75 dB(A) | Approx75 dB(A) | |

Clinch Module Movement | AC Servo Motor ( Up, Down ) | Air Cylinder ( Up, Down ) | |

Tape Cutter | Single Stroke Cutting Feature , | Single Stroke Cutting Feature , | |

Station Feeding System | High Speed Valve | STD Valve | |

Component Transfer Assemble CTA | AC Servo Motor | Pneumatic Cylinder | |

Position Teaching | Systém Vision | Systém Vision | |

Multi Fiducial ( option ) | Multi Fiducial ( option ) | ||

Axis Driving System | AC Servo Motor | AC Servo Motor | |

Data Input Style | USB Port (Excel Format) | USB Port (Excel Format) | |

Operation System | Chinese/English Interface (Windows? Platform) LCD Display | Chinese/English Interface (Windows? Platform) LCD Display | |

Operation Mode | Auto / Semi Auto | Auto / Semi Auto | |

Component Density | High Density Insertion Style | High Density Insertion Style | |

Worktable Rotation | Conveyor Track | Conveyor Track | |

Board Inload | Conveyor Inload Left to Right(Selectable) | Conveyor Inload Left to Right(Selectable) | |

Programovanie | On-line Teaching | On-line Teaching | |

Loader/Unloader | Možnosť | Možnosť |