На фоне взрывного роста рынка автомобилей, работающих на новых источниках энергии, автомобильная электроника переживает комплексную модернизацию, характеризующуюся "высокой плотностью, высокой надежностью и высокой сложностью". Требования к интеграции и точности электронных компонентов - от электронных блоков управления и систем управления батареями до интеллектуальных модулей кабины - значительно превышают требования к традиционным автомобилям. Однако большинство производственных линий SMT автопроизводителей все еще придерживаются стандартов оборудования эпохи бытовой электроники, сталкиваясь с такими проблемами, как колебания производительности, недостаточная совместимость процессов и чрезмерный углеродный след. Мы рассмотрим болевые точки, методы модернизации и конкретные примеры, чтобы логически обсудить и проанализировать цель модернизации технологий производства SMT для этих новых энергетических транспортных средств.

Во-первых, новые энергетические транспортные средства требуют усовершенствований от машин для подбора и установки SMT. Они подразделяются на три категории. Первая категория - точность и надежность. Это базовая защита для безопасности не только пассажиров, но и самого транспортного средства. Требования к SMT для этой категории - миниатюризация компонентов микросхем: где микросхемы BMS и платы драйверов IGBT должны поддерживать компоненты 01005 (0,4 мм × 0,2 мм) и упаковку QFN с шагом 0,3 мм, с динамической точностью размещения ≤0,025 мм@3σ. И совместимость в тяжелых условиях эксплуатации: автомобильная электроника должна выдерживать температурные циклы от -40°C до 150°C, а уровень дефектов паяных соединений должен быть менее 50 ppm (пятьдесят частей на миллион); Вторая категория - эффективность и гибкость. Как правило, она предназначена для реагирования на давление при наращивании мощности. Требования к SMT для этой категории - многопродуктовые смешанные линии: где с помощью ускорения итерации моделей автомобилей время переналадки линии должно быть сокращено до менее чем 15 минут.

И спрос на производственные мощности: где ежемесячная производственная мощность одной производственной линии SMT обычно должна превышать 50 миллионов точек, с коэффициентом использования ≥95%; Третья категория - зеленое производство. Она предназначена для жестких ограничений в рамках политики ESG. Требования к SMT для этой категории - бессвинцовое производство: где соблюдаются RoHS, REACH и другие нормы, с остатками тяжелых металлов в припое ≤0.1%. И управление углеродным следом: потребление энергии оборудованием должно быть снижено на 20%-30%.

Во-вторых, производственная линия SMT для новых энергетических автомобилей имеет четыре технологические болевые точки, о которых стоит упомянуть. Первая болевая точка - недостаточная точность, приводящая к узким местам в производстве. Причина в том, что при монтаже компонентов 01005 на традиционной машине для подбора и установки выход продукции обычно меньше 98%, а затраты на доработку резко возрастают; вторая болевая точка - низкий уровень автоматизации. Причина в том, что зависимость от ручной настройки приводит к тому, что количество брака достигает 0,2%, а оптимизация параметров процесса затягивается; третья болевая точка - низкое соответствие экологическим нормам. Причина в том, что существует высокая вероятность того, что припои на основе свинца и высокоэнергоемкие машины для сборки и размещения, машины для пайки столкнутся с риском экспортных санкций; Последняя болевая точка - слабые гибкие производственные мощности. Причина в том, что смена линий обычно занимает более 30 минут, что затрудняет работу с колебаниями заказов на несколько моделей автомобилей.

В-третьих, мы хотим обсудить путь технической трансформации. С нашей точки зрения, это может быть комбинация обновления оборудования, расширения возможностей программного обеспечения и "зеленой" трансформации. Мы разделим его на три основных аспекта. Давайте углубимся в каждый аспект с его обоснованием. Во-первых, при модернизации оборудования мы хотим сосредоточиться на укреплении основ точного производства. Есть два типа машин, которые могут быть модернизированы: высокоточные машины для подбора и размещения: где мы можем заменить линейный двигатель с магнитной левитацией, улучшив динамическую точность до 0,035 мм@3σ и модернизировав оптическую систему выравнивания для поддержки распознавания точек маркировки на уровне 30 мкм. И машины для пайки азотом: мы можем управлять контролем содержания кислорода, чтобы оно было меньше и равнялось 100 ppm, уменьшая окисление паяных швов и повышая выход продукции на 1,5%. Во-вторых, для расширения возможностей программного обеспечения мы хотим сосредоточиться на создании ядра интеллектуальной и автоматизированной управляемой фабрики. Существует два типа интеллектуальных систем, которые могут быть оптимизированы: Система оптимизации процессов ИИ: она обеспечивает машинное обучение и анализ данных о выбросе материала в реальном времени для динамической корректировки траектории сопла, что позволяет снизить скорость выброса материала с 0,2% до 0,08%. Затем с помощью технологии цифрового двойника моделируется производственный процесс, что сокращает цикл внедрения нового продукта на 60%. И глубокая интеграция с MES, обеспечивающая мониторинг в реальном времени общей эффективности оборудования, энергопотребления, выхода продукции и других показателей, с повышением скорости реагирования на аномалии на 70%. В-третьих, для "зеленой" трансформации мы хотим сосредоточиться на соблюдении требований и снижении затрат. Для достижения этой цели есть два разумных способа: бессвинцовая технология пайки: где используется сплав Sn-Ag-Cu. И интеллектуальное управление энергопотреблением: где мы можем добавить модуль переменной частоты и систему рекуперации тепла, чтобы снизить энергопотребление оборудования на 25%.

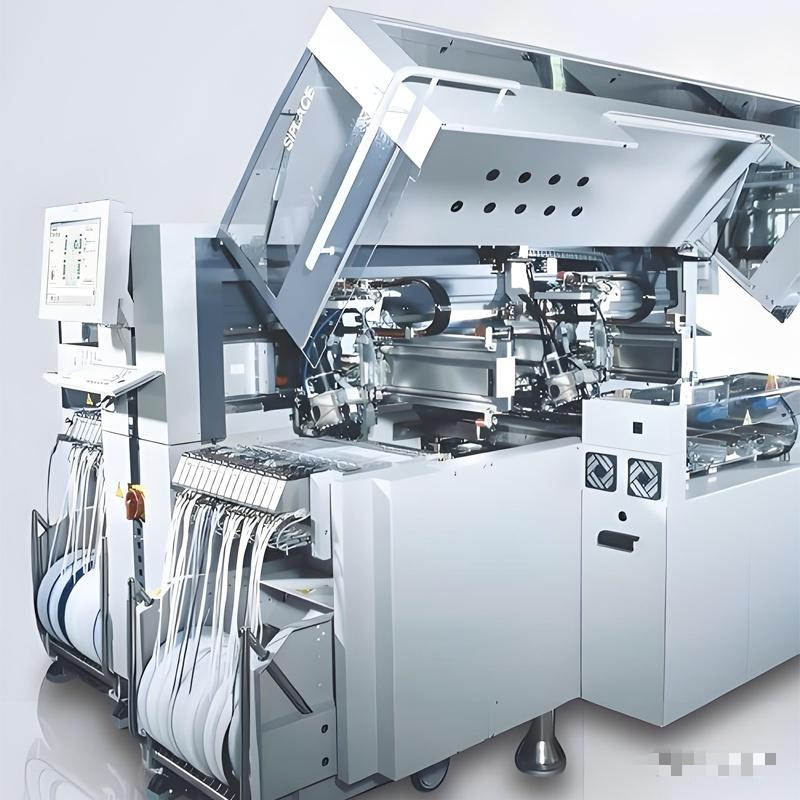

В-четвертых, мы хотим рассказать о конкретном примере, связанном с этой модернизацией в прошлом. Речь идет об одном из наших прошлых клиентов, производителе новых энергетических транспортных средств, который столкнулся с огромными штрафными санкциями из-за задержек поставок, вызванных недостаточным выходом модулей BMS. Их действия можно разбить на три этапа: сначала они приобрели несколько станков Nectec NT-T5 с точностью 0,035 мм @ 3σ. Затем они добавили к этим машинам модуль предупреждения о выбросе материала AI и интерфейс MES. И наконец, они заменили печь для пайки азотом на печь для пайки бессвинцовой пастой. В результате этой модернизации компания добилась следующих результатов: выход продукции увеличился до 99,5%, что позволило сократить ежегодные расходы на ремонт на 12 миллионов юаней; скорость наращивания производственных мощностей увеличилась на 50%, цикл доставки заказов сократился до 18 дней; снижение выбросов углекислого газа на единицу продукции на 28%.

В-пятых, мы хотим обсудить будущие перспективы этой тенденции модернизации производственных линий. Очень важно упомянуть о таком контексте, поскольку он способствует конвергенции технологий и регионализации производства. Во-первых, мы предполагаем, что лазерная сварка, 3D SPI-инспекция и другие технологии будут интегрированы в производственную линию SMT для достижения контроля процесса на нанометровом уровне. Во-вторых, очевидно, что спрос на подержанное оборудование в Юго-Восточной Азии, Восточной Европе и других регионах высок. Обязательным и одним из факторов победы в гонке является предоставление локализованного способа оплаты и быстрого обслуживания клиентов. Наконец, поскольку мир продолжает продвигать возобновляемые и зеленые источники энергии, в будущем мы увидим больше фотоэлектрических источников питания, восстановления оборудования и модернизации торговли углеродными кредитами.

В заключение следует отметить, что технологическая трансформация SMT-оборудования для энергетических транспортных средств - это не просто замена оборудования, а комплексная модернизация всей цепочки, сочетающая в себе "точное мастерство + интеллектуальные системы + зеленые стандарты". Для автопроизводителей выбор партнера с возможностями межпроцессной интеграции и глобальной сервисной сетью, такого как Nectec, станет ключом к преодолению двойного давления - производственных мощностей и соответствия требованиям.