SMT - это технология, при которой компоненты поверхностного монтажа припаиваются к поверхности печатной платы. По сравнению с традиционной технологией сборки со сквозными отверстиями, эта технология обладает такими преимуществами, как высокая плотность монтажа, малый размер изделия (например, уменьшение размера с 40% до 60%), малый вес (например, уменьшение веса с 60% до 80%), высокая надежность, сильная виброустойчивость и простота автоматизации. По прогнозам ведущего международного финансового исследовательского института, в 2024 году мировой рынок печатных плат достигнет общей стоимости в $73 миллиарда долларов США, что означает рост на 6% в год.

В перспективе, по мере того как технология искусственного интеллекта будет ускоренными темпами внедряться в устройства конечных пользователей, взрывной рост глобальных краевых устройств с поддержкой искусственного интеллекта станет ключевым фактором структурной модернизации индустрии печатных плат. По данным организации, ожидается, что в период с 2025 по 2029 год объем производства печатных плат в мире будет расти со среднегодовым темпом 5% и к 2029 году достигнет более 90 миллиардов долларов США. На фоне активного роста отрасли производства печатных плат параллельно развивается и соответствующая отрасль SMT-сборки, а также растет спрос на оборудование для рентгеновского контроля. Ожидается, что потенциальная емкость рынка оборудования для рентгеновского контроля будет расти и дальше.

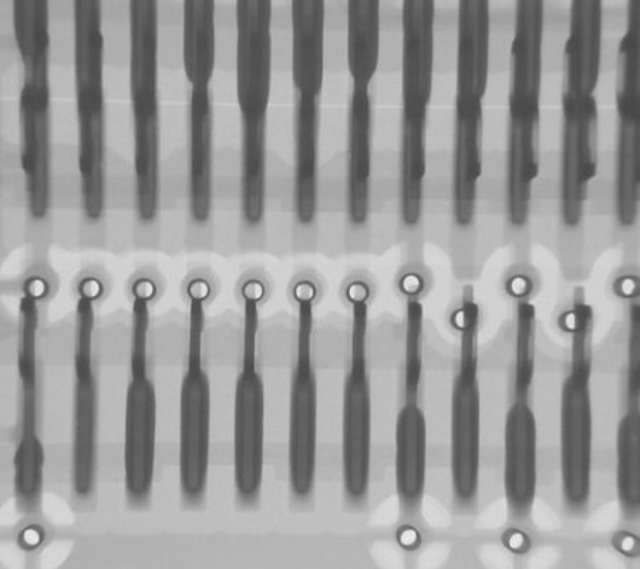

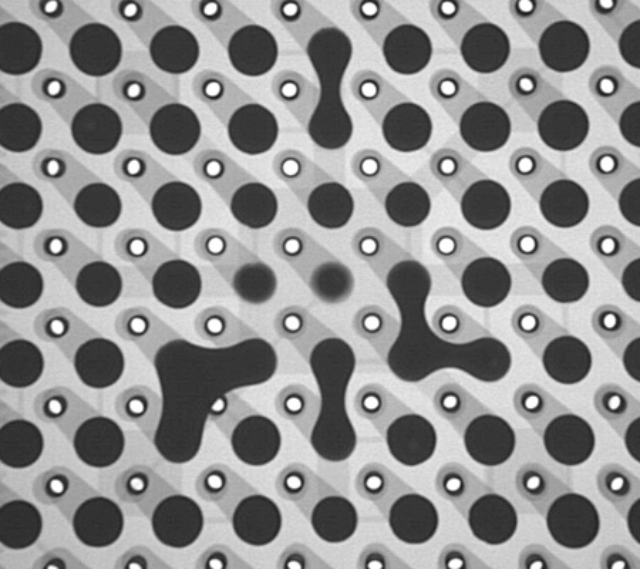

В области рентгеновского контроля электронного производства оборудование для микрофокусного рентгеновского контроля позволяет выявить внутреннюю структуру компонентов, обнаружить различные дефекты, скрытые внутри упаковки, включая холодные паяные соединения, перекрытия, недостаточное количество припоя, пустоты и отсутствующие компоненты. Оно также может выявлять трещины во внутренних слоях печатных плат и внутренние структуры, невидимые невооруженным глазом или не обнаруживаемые с помощью онлайн-тестирования. Это позволяет эффективно проверять дефекты пайки в BGA, CSP и других процессах упаковки в печатные платы, предоставляя отрасли поверхностного монтажа SMT универсальное решение для проверки, оптимизируя технологический процесс SMT и расширяя возможности оценки качества.

Дальнейший анализ показывает, что ценность рентгеновского контроля выходит далеко за рамки помощи клиентам в выявлении дефектов. Это также мощный инструмент контроля и оптимизации процессов. Благодаря статистическому анализу данных контроля и непрерывному мониторингу количества пустот, размеров и округлости паяных соединений BGA заказчики могут получить представление о тонких колебаниях и потенциальных тенденциях в процессе производства SMT. Этот цикл обратной связи, основанный на данных, позволяет инженерам точно корректировать параметры печати паяльной пасты, точность укладки или температурные кривые пайки оплавлением, тем самым устраняя дефекты на начальном этапе их возникновения. Это означает переход от обнаружения к предотвращению, что значительно повышает выход продукции и общую эффективность производства.

В заключение следует отметить, что по мере дальнейшего развития PCBA в направлении повышения плотности, надежности и сложности, рентгеновский контроль перестает быть просто вспомогательным инструментом, а становится стратегической инвестицией, обеспечивающей качество продукции, доверие клиентов и укрепляющей конкурентоспособность на рынке. В условиях растущей конкуренции на рынке компании, которые внедряют и эффективно используют эту передовую технологию контроля, такие как Nectec, несомненно, получат конкурентное преимущество и будут уверенно решать будущие технические задачи.