В сфере охранного видеонаблюдения надежность продукции PCBA для сборки печатных плат напрямую влияет на стабильную работу оборудования и безопасность данных. В условиях сложной и меняющейся внешней среды, такой как высокая температура, повышенная влажность, пыль, вибрация и грозовые помехи, повышение уровня защиты PCBA с помощью технологии обработки SMT-чипов стало ключевым моментом технологического обновления в отрасли. Мы объединим весь процесс обработки PCBA, чтобы изучить основную роль обработки SMT-чипов в повышении эффективности защиты продуктов охранного видеонаблюдения.

Прежде всего, давайте обсудим требования к степени защиты PCBA для систем видеонаблюдения. Эти устройства PCBA обычно должны быть развернуты в суровых условиях окружающей среды или на производстве. Существует несколько проблем, с которыми им придется столкнуться. Первая задача - адаптация к окружающей среде, где устройства PCBA должны соответствовать классу защиты IP67 или выше, чтобы предотвратить проникновение дождевой воды и пыли; вторая задача - погодоустойчивость, где устройства PCBA должны выдерживать изменения температуры от -40°C до 85°C, предотвращая ложную пайку, вызванную тепловым расширением и сжатием компонентов; третья задача - виброустойчивость, где они могут положительно снизить риск отсоединения компонентов, вызванный ветром и механической вибрацией; четвертая задача - электромагнитная совместимость, где они могут предотвратить скачки напряжения и электростатический разряд от повреждения чувствительных чипов.

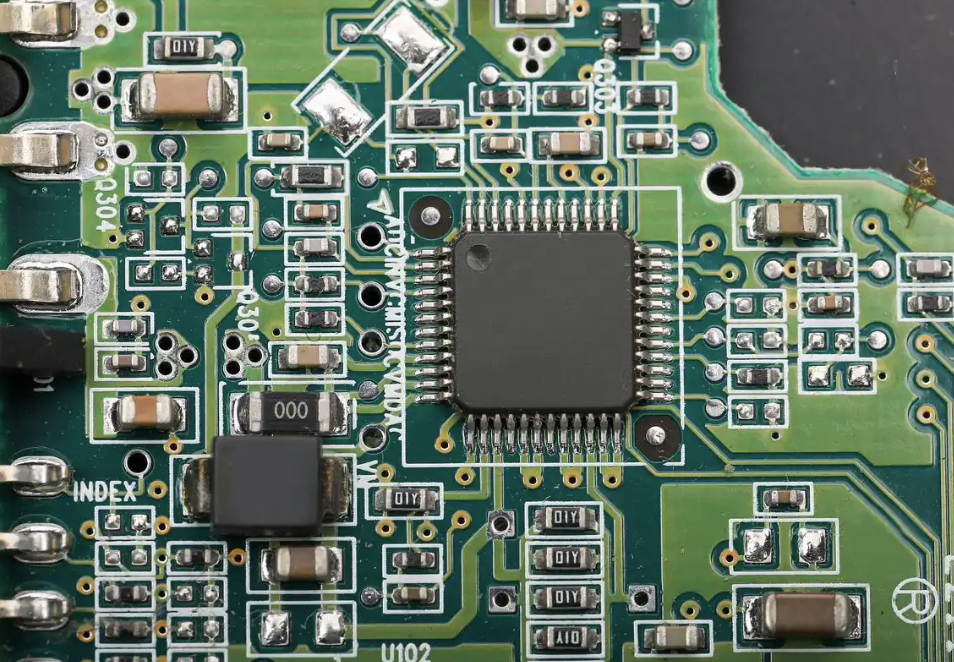

Во-вторых, давайте обсудим основные технологии защиты для процесса производства SMT. В процессе монтажа микросхем SMT используются прецизионные технологии производства и инновационные материалы для создания многослойной системы защиты для контроля безопасности PCBA. Существует несколько слоев защиты, о которых стоит упомянуть. Первый слой - технология высокоточного монтажа, улучшающая герметичность, где используются микроупакованные компоненты, такие как 0201, для уменьшения расстояния между компонентами и сокращения путей проникновения пыли, а также укрепление больших микросхем, таких как BGA и QFN, с помощью клея для нижнего заполнения для повышения виброустойчивости; второй слой - технология трехслойного покрытия, где используется акриловая, полиуретановая или силиконовая трехслойная краска для формирования защитной пленки толщиной 0.1-0,3 мм защитной пленки, которая блокирует влагу, солевой туман и химическую коррозию, а технология распыления позволяет точно защитить такие области, как разъемы и тестовые точки, избегая влияния на теплоотдачу. В результате PCBA, обработанные тройным защитным покрытием, сохраняют 90% сопротивления изоляции в условиях 85°C/85% RH; третий слой - система защиты от электростатических разрядов, где на заводах необходимо поддерживать температуру 22-28°C и влажность 40-70% RH, затем установить антистатические полы и обязать персонал носить антистатическую одежду и браслеты. Еще важнее, чтобы машины для укладки SMT, печи для дожигания и другое оборудование использовали независимое заземление для предотвращения воздействия электрических утечек на PCBA. С другой стороны, стандарт защиты также относится к этому уровню, где он был повышен до HBM 4000V в соответствии со стандартом ANSI/ESD S20.20; четвертый уровень - высоконадежные методы пайки, где используется сверхтонкая порошковая паяльная паста Type 5 или выше для снижения уровня пустот при пайке до менее 5% и мониторинг в реальном времени с помощью SPI и AOI для обеспечения полноты паяного соединения больше или равной 75%.

Более того, использование комбинации OSP и процесса погружения в серебро для областей с высоким уровнем нагрева, таких как модули источников питания, позволяет повысить устойчивость паяных соединений к термоциклированию.

В-третьих, давайте посмотрим на перспективы развития автоматизации и интеграции защиты для PCBA мониторинга безопасности с помощью SMT-технологий. С повышением требований к мониторингу безопасности обработка микросхем SMT развивается в следующих направлениях. Первое направление - техника встроенной защиты. Она заключается в интеграции ESD-подавителей и EMI-фильтров непосредственно в PCBA; второе направление - управление производством с помощью искусственного интеллекта. Оно заключается в том, что с помощью машинного зрения в режиме реального времени определяется качество паяного соединения и динамически настраиваются параметры пайки; третье направление - возобновляемые защитные материалы. Предлагается разработать тройные защитные покрытия на водной основе и упаковочные материалы на биооснове, чтобы снизить воздействие на окружающую среду.

В заключение можно сказать, что результатом повышения степени защиты PCBA для систем видеонаблюдения является глубокая интеграция точности сборки SMT, материаловедения и управления процессом. Благодаря высокоточной сборке, трехслойному защитному покрытию, электростатической защите и полной координации процесса технология SMT не только обеспечивает охранное оборудование "защитной броней", но и продвигает отрасль к высокой надежности и интеллекту.