De kern van röntgeninspectietechnologie ligt in het gebruik van de doordringende eigenschappen van röntgenstralen om de interne structuur van objecten zichtbaar te maken. Wanneer röntgenstralen door materialen van verschillende dichtheid gaan, worden ze door deze dichtheidsverschillen in verschillende mate geabsorbeerd, waardoor overeenkomstige interne beelden worden gevormd. Meer specifiek vertonen dichtere metalen materialen, zoals soldeerverbindingen, een sterke absorptie van röntgenstralen, wat resulteert in duidelijke contourbeelden. Daarentegen absorberen materialen met een lagere dichtheid, zoals PCB-substraten of holtes binnen soldeerverbindingen, minder röntgenstraling, wat leidt tot verschillende grijstinten in de beelden. Nadat de inspectieapparatuur deze verschillen nauwkeurig heeft vastgelegd, kan het nauwkeurige beelden samenstellen van de interne structuur van het object, wat intuïtief bewijsmateriaal oplevert voor de daaropvolgende detectie en analyse van defecten.

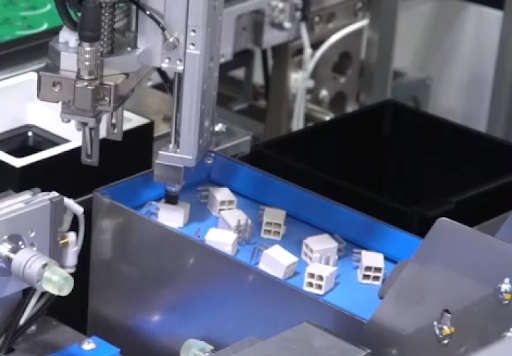

Eerst willen we de toepassing van röntgeninspectietechnologie in de SMT-industrie bespreken. Bij SMT-assemblage bevinden de soldeerbolletjes van verpakkingstypes zoals BGA (ball grid array) en CSP (chip-scale packaging) zich onderaan de pinnen en worden de soldeerverbindingen bedekt door het verpakkingslichaam, waardoor het moeilijk is voor traditionele optische inspectie (AOI) om de soldeerkwaliteit effectief te controleren. De eerste toepassing is inspectie van soldeerleemtes: als tijdens het reflow soldeerproces het gas in de soldeerpasta niet volledig kan worden verwijderd, zullen er leemtes ontstaan in de soldeerverbindingen. De aanwezigheid van deze holtes verzwakt de structurele sterkte van de soldeerverbindingen, vermindert hun elektrische geleidbaarheid en kan zelfs voortijdige uitval van elektronische componenten veroorzaken. De tweede toepassing is de inspectie van soldeerbruggen: tijdens het soldeerproces kan overmatig soldeer of een onnauwkeurige plaatsing van soldeerzolen brugvorming tussen soldeerverbindingen veroorzaken. Overbrugging kan de normale elektrische prestaties van het circuit verstoren en fouten zoals kortsluiting veroorzaken. Röntgeninspectie kan duidelijk de verdeling van soldeer tussen soldeerverbindingen laten zien, nauwkeurig detecteren of er sprake is van overtollige soldeerbruggen, ervoor zorgen dat de elektrische prestaties van het circuit voldoen aan de ontwerpvereisten en dit veiligheidsrisico onmiddellijk elimineren; De derde toepassing is detectie van open en koude soldeerverbindingen: in sommige gevallen kunnen er door onvolledig smelten van soldeer of onjuiste laswerkzaamheden koude soldeerverbindingen of open circuits ontstaan. Deze laskwesties kunnen de elektrische geleiding van circuits ernstig verstoren, waardoor elektronische apparaten defect raken. Met röntgeninspectie kunnen de dichtheid en vorm van soldeerverbindingen nauwkeurig worden gedetecteerd, waardoor defecten zoals koude soldeerverbindingen en open circuits effectief worden geïdentificeerd. Dit levert nauwkeurig bewijs voor tijdige reparaties en garandeert de prestaties en kwaliteit van elektronische producten.

Ten tweede willen we enkele unieke voordelen van röntgeninspectietechnologie bespreken. Het eerste voordeel is de verliesvrije inspectiekenmerken: Röntgeninspectie is een niet-destructieve testmethode die geen fysieke schade toebrengt aan printplaten of gelaste onderdelen. Deze eigenschap stelt fabrikanten in staat om de kwaliteit van lassen tijdens het productieproces in realtime te controleren, potentiële problemen snel te identificeren en op te lossen, zonder zich zorgen te maken over een nadelige invloed op de prestaties van het eindproduct. Vergeleken met sommige destructieve testmethoden kan röntgeninspectie de productkwaliteit garanderen en tegelijkertijd de testkosten verlagen en de productie-efficiëntie verbeteren: Röntgeninspectietechnologie kan beelden met hoge resolutie produceren van kleine details zoals soldeerverbindingen, waardoor een uitgebreide en gedetailleerde inspectie van de laskwaliteit mogelijk is. Zelfs interne defecten die moeilijk te detecteren zijn met traditionele inspectiemethoden kunnen duidelijk worden onthuld met röntgenbeelden, waardoor inspecteurs nauwkeurige en betrouwbare inspectieresultaten krijgen. Het derde voordeel is de mogelijkheid om complexe verpakkingsstructuren te weerstaan: met de ontwikkeling van de elektronica-industrie worden PCB's met complexe verpakkingsstructuren met hoge dichtheid, zoals BGA, CSP en PoP, steeds gebruikelijker. De soldeerkwaliteit van deze verpakkingsvormen is kritisch voor de prestaties van de hele printplaat, maar traditionele inspectiemethoden hebben vaak moeite om hiermee om te gaan. Röntgeninspectietechnologie, met zijn krachtige penetratiemogelijkheden en precieze beeldvormingseffecten, kan gemakkelijk voldoen aan de inspectievereisten van deze complexe verpakkingsstructuren, waarbij mogelijke soldeerdefecten onmiddellijk worden geïdentificeerd en hersteld om de hoogwaardige werking van de printplaat te garanderen;

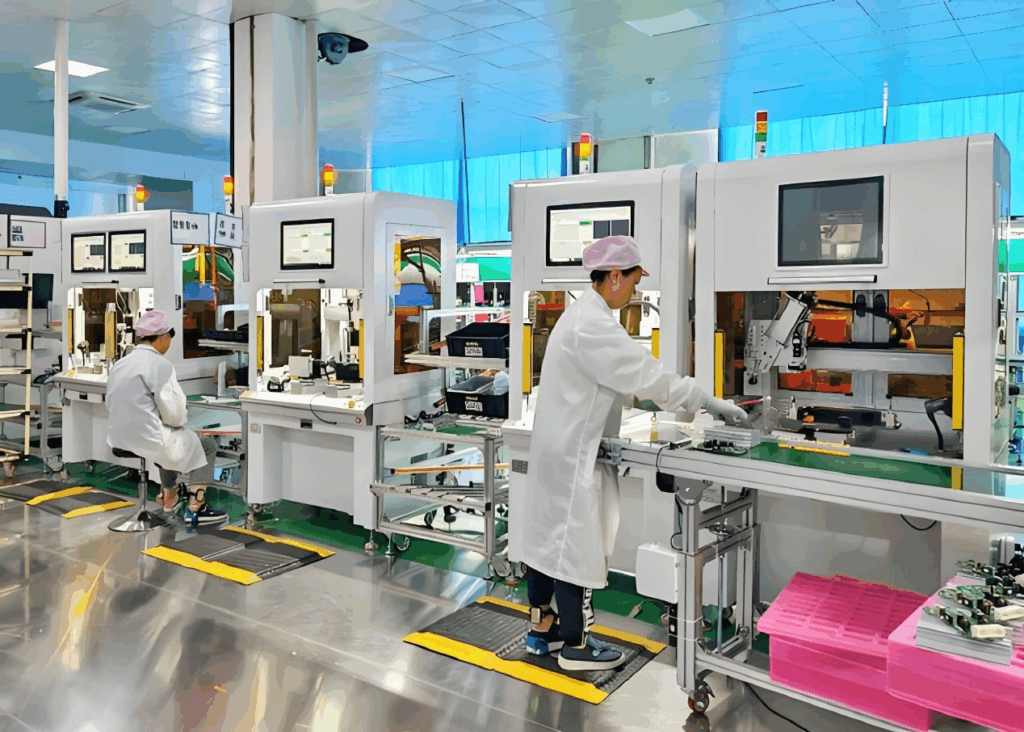

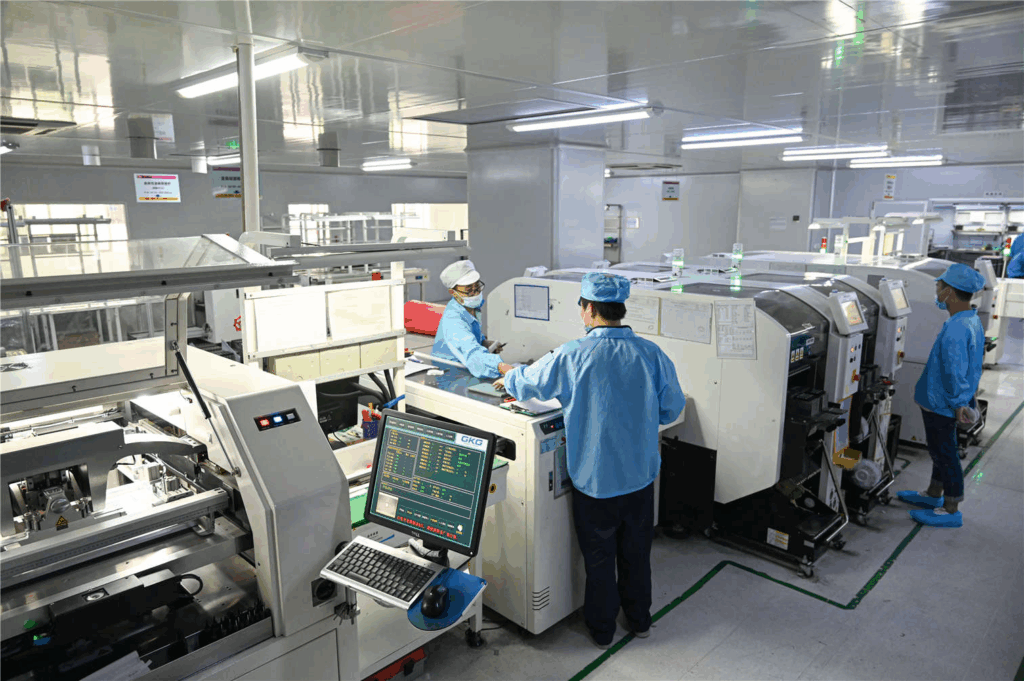

Het vierde voordeel is de ondersteuning van batchtesten en geautomatiseerde productie: Röntgeninspectietechnologie kan niet alleen worden gebruikt voor individuele PCB-inspectie, maar ook voor online inspectie in massaproductieprocessen. In combinatie met geavanceerde automatiseringsapparatuur maakt röntgeninspectie een snelle en efficiënte kwaliteitscontrole in grootschalige productieprocessen mogelijk. Dit verbetert niet alleen de productie-efficiëntie, maar zorgt er ook voor dat de soldeerkwaliteit van elke PCB aan strenge normen voldoet, wat een sterke garantie biedt voor de stabiele productie van elektronische producten.

Ten derde willen we enkele veel voorkomende problemen bespreken die zich voordoen tijdens de röntgeninspectieprocedure, evenals de bijbehorende oplossingen. Het eerste probleem is soldeerleemte: Voids in soldeerverbindingen zijn een van de meest voorkomende defecten in SMT-assemblage, vooral tijdens het BGA-solderen. Te grote holtes kunnen de mechanische sterkte en de elektrische geleiding van soldeerverbindingen verzwakken en de stabiele werking van elektronische componenten beïnvloeden. Het tweede probleem is de vervorming of indrukking van de soldeerbal: tijdens het BGA-soldeerproces kan de vervorming of indrukking van soldeerballen de soldeerresultaten ernstig beïnvloeden. Abnormale soldeerbalvormen kunnen leiden tot slecht contact bij soldeerverbindingen, verminderde elektrische geleiding en zelfs vals solderen. Om dit probleem op te lossen, kan röntgeninspectie duidelijk abnormale soldeerbalvormen detecteren en vroegtijdig waarschuwen voor problemen met de soldeerkwaliteit;

Het derde probleem is de verkeerde uitlijning van chipcomponenten: tijdens het SMT-assemblageproces kunnen werkstukken verkeerd worden uitgelijnd door machinestoringen, operatorfouten of problemen met de materiaalkwaliteit. Een verkeerde uitlijning van werkstukken kan de installatienauwkeurigheid en elektrische prestaties van elektronische componenten beïnvloeden, wat kan leiden tot productstoringen. Om dit probleem op te lossen, kan röntgeninspectie de nauwkeurige positie van werkstukken controleren en uitlijningsfouten direct detecteren en corrigeren.

Kortom, in de moderne elektronicaproductie worden elektronische componenten en printplaten steeds kleiner en complexer, wat hogere eisen stelt aan de inspectietechnologie voor SMT-assemblage. Röntgeninspectietechnologie, met zijn efficiënte, niet-destructieve en nauwkeurige inspectievoordelen, is een effectief middel geworden om soldeerdefecten aan te pakken die traditionele optische inspectiemethoden niet adequaat kunnen aanpakken. Het garandeert niet alleen de betrouwbaarheid van het solderen van printplaten met hoge dichtheid, maar verbetert ook aanzienlijk de kwaliteitscontrole tijdens het hele productieproces.