FX-3RA|高速モジュラーマウンター</trp-post-container

JUKI FX-3RA SMT装置**は、24ノズルの同期配置と新レーザー認識技術を採用した高速・高精度SMT装置です。0402~33.5mm部品(QFP/BGA含む)に対応し、理論速度90,000CPH、精度±0.05mmを実現しました。リニアサーボモーターとマグネットサスペンションドライブを搭載し、安定性と効率性を確保。ミックスフィーダーや超長尺基板(最大800×560mm)に対応し、LEDやカーエレクトロニクスなど多様化する生産ニーズに応える。モジュール設計と低メンテナンス特性は、生産ラインの柔軟性と信頼性を大幅に向上させます。

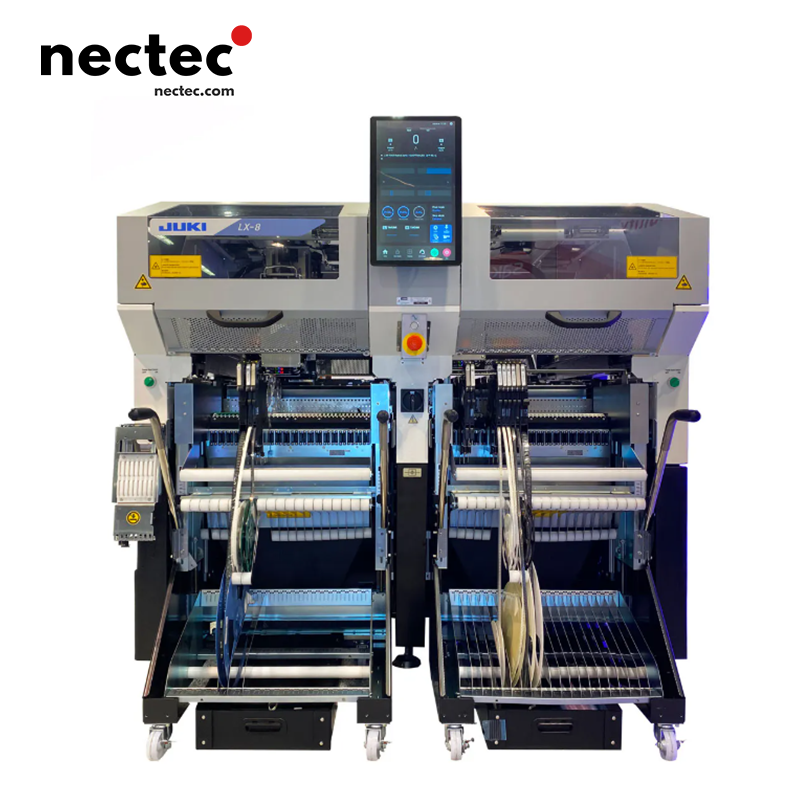

FX-3RA|高速モジュラーマウンター

- 説明

説明

プレースメントヘッド&レーザー計測システム

マルチヘッド並列アーキテクチャ

- 24ノズルマルチヘッドシステム:6つの独立したノズルを持つ4つの配置ヘッドが、同期したピックアンドプレース動作を可能にし、超高速スループットを実現。

- LNC60レーザースキャニングモジュール:新世代のレーザーセンサーは、6つのノズルすべてで並列部品識別をサポートし、従来の4ノズルシステムよりも20%速い認識スループットを実現。0402(0.4×0.2mm)~33.5mm²の部品(QFP/CSP/BGA)を±50μm(±3σ)の測定精度でカバー。

- 機内コンポーネント検証:高速ヘッド移動中のリアルタイムレーザー検査により、アイドルタイムを最小化し、配置効率を高めます。

ビジョン&モーション・コントロール・システム

先進のドライブ技術

- X/Y軸リニアサーボドライブ:0.001mm分解能のリニア磁気スケールによる完全クローズドループ制御により、高加速度動作とサブミクロンの位置決め精度を実現。

- 非接触磁気浮上:摩擦のないリニアモーター設計により、メンテナンスフリーを実現し、機器の寿命を延ばし、従来のリードスクリューシステムを凌ぐ加速性能を発揮します。

- デュアルサーボY軸アクチュエーション:高速運転時のコンベアの安定性を最適化し、振動による配置ミスを軽減します。

フィーダーシステム

ハイブリッド給餌エコシステム

- 240ステーション給餌プラットフォーム:電動・メカ混在テープフィーダー(8mm相当)に対応し、多様な生産ニーズに最大240個まで対応。

- インテリジェント給餌技術自動テープスプライシングとリアルタイムの不足アラートを備えたeフィーダーは、手作業を減らし、中断のない生産を維持します。

PCBハンドリングシステム

多目的な基板管理

- 標準/拡張フォームファクター:

- Lタイプ:410×360mm

- XLタイプ610×560mm

- 拡張:800×560mm:超長尺プリント基板(LED照明、車載電子機器)用。

- サーボ駆動アクティブ・ダンピング・プラットフォーム:固定時の基板振動を低減し、配置オフセットを最小限に抑え、セットアップ時間を短縮。

ソフトウェアとヒューマン・マシン・インターフェース

インテリジェントな生産オーケストレーション

- 動的軌道最適化:AI駆動アルゴリズムが最適な配置パスを自動生成し、理想的な条件下で90,000CPHの理論スループットを達成。

- 15″タッチスクリーンHMI:配置状況、ミスピック率、故障診断をリアルタイムで監視できる直感的なグラフィカル・インターフェース。

- モジュラー・ライン・インテグレーション:JUKI KEシリーズに対応し、機種混在ラインにも柔軟に対応。

真空システムとメンテナンス設計

信頼性工学

- 高効率真空ポンプ:エア消費量を削減し、部品ピックアップの安定性を高め、ミスピック率を低減。

- ツールレスモジュラーメンテナンス:クイックチェンジノズル/フィーダーと無潤滑eFeeder設計により、ダウンタイムとメンテナンスコストを最小限に抑えます。

- メンテナンスフリーの磁気ドライブ:非接触浮上技術により、機械的摩耗がなく、寿命が延びる。

技術的メリットの概要

- 超高スループットリニアサーボドライブとパラレルレーザー検査により、90,000CPHの設置速度を実現。

- 精密計測Cpk≧1.5プロセス対応のファインピッチ部品(QFP/BGA)で±50μmの精度を実現。

- スケーラブルな柔軟性:ハイブリッド給電、長尺プリント基板、多機種ライン統合に対応。

- 低い総所有コスト(TCO):磁気浮上、モジュール設計、インテリジェント・メンテナンスにより、運用コストを削減。

スペック

アイテム/モデル | 高速モジュラーマウンター | 高速モジュラーマウンター | FX-3RA(FX-3RAL、FX-3RAXLを含む) | |

FX-3RAL | FX-3RAXL | 特徴 | ||

ボードサイズ | Lサイズ(410x360mm) | はい | いいえ | 1.0402mm(01005 inch) ~ 33.5mm×33.5mm 2.レーザー認識:±0.05mm(±3σ) 3.内蔵レーザーによるオンザフライセンタリング 4.2ステーション、4ガントリー、4プレースメントヘッド、24ノズル 5.フルクローズドループ制御リニアサーボモータXYドライブ 6.最大240個の部品を収納可能 7.電気式または機械式フィーダートローリー |

Lワイドサイズ(510×360mm)※1 | はい | いいえ | ||

XLサイズ(610×560mm) | いいえ | はい | ||

長尺プリント配線板への適用性 | 800×360mm | 800×560mm | ||

コンポーネントの高さ | 6mm | はい | ||

コンポーネント・サイズ | レーザー認識 | 0402(01005) ~ 33.5mm×33.5mm | ||

プレースメント速度(チップ) | 最適 | 0.040秒/チップ(90,000CPH)*2 | ||

IPC9850 | 66,000CPH | |||

プレースメントの精度 | レーザー認識 | ±0.05mm(±3σ) | ||

フィーダー入力 | 8mmテープの場合、最大240 (電気式ダブルテープフィーダー) | |||