L'apparecchiatura di ispezione a raggi-X è uno strumento fondamentale per i test non distruttivi di alta precisione e svolge un ruolo vitale in diversi settori high-tech, tra cui le comunicazioni 5G, il settore aerospaziale, l'imballaggio elettronico dei semiconduttori, la tecnologia SMT (Surface Mount Technology), i LED, i connettori, i fili, le batterie al litio e i condensatori. Vi spiegheremo in dettaglio le applicazioni delle apparecchiature di ispezione a raggi X in questi settori e il valore che apportano.

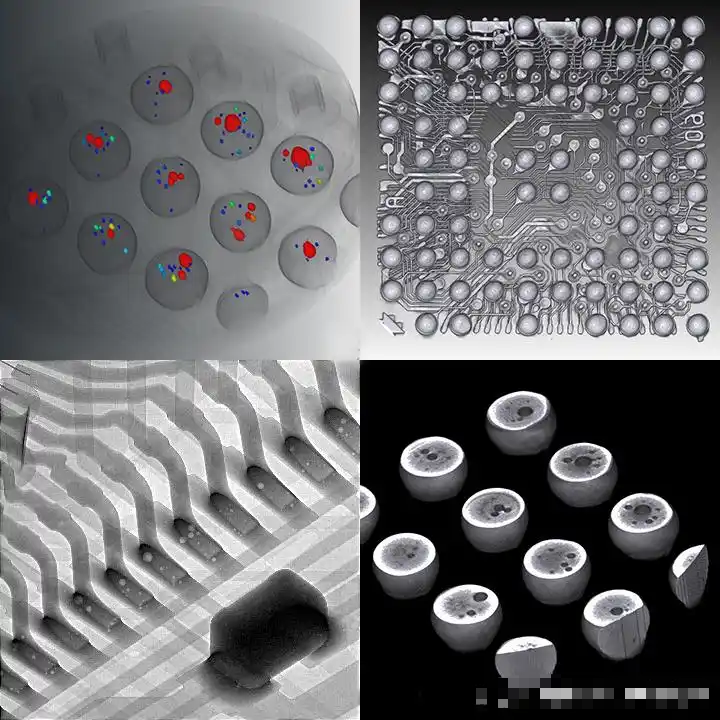

Il primo settore è quello delle telecomunicazioni 5G. Le applicazioni di SMT nel 5G sono illimitate. Le macchine di ispezione a raggi X sono utilizzate principalmente per ispezionare la struttura interna e la qualità delle connessioni di componenti chiave come chip RF, moduli a microonde e array di antenne. Con le caratteristiche di alta velocità e alta frequenza dei dispositivi 5G, i componenti stanno diventando sempre più miniaturizzati e integrati, con conseguenti requisiti più severi per il rilevamento dei difetti interni. Per i suoi valori, dispone di capacità di rilevamento di microdifetti. Utilizzando la tecnologia di imaging a raggi X ad alta risoluzione, è in grado di rilevare microdifetti come piccoli giunti di saldatura, crepe interne e pori per garantire la stabilità e l'affidabilità delle apparecchiature durante il funzionamento ad alta frequenza. Ha anche capacità di controllo della qualità dell'imballaggio. Rileva la qualità dell'imballaggio dei chip RF per prevenire i problemi di trasmissione del segnale causati da un imballaggio scadente, migliorando così le prestazioni e la durata delle apparecchiature di comunicazione 5G.

Il secondo settore è quello della produzione aerospaziale. Queste industrie aerospaziali hanno requisiti di affidabilità estremamente elevati per i materiali. Le apparecchiature di ispezione a raggi X vengono utilizzate per rilevare i difetti interni delle strutture composite, dei componenti dei motori (come le pale delle turbine) e delle apparecchiature elettroniche di bordo per garantire la sicurezza in condizioni estreme.

Per i suoi valori, è dotato di controlli non distruttivi di alta precisione. L'apparecchiatura a raggi X è in grado di identificare difetti come delaminazione, crepe e bolle nei materiali compositi, garantendo la resistenza e la stabilità dei materiali. Inoltre, è in grado di eseguire test su strutture complesse. Nel collaudo dei componenti dei motori, le apparecchiature a raggi X possono identificare con precisione i microdifetti interni, evitando le conseguenze catastrofiche causate dai difetti e migliorando la sicurezza di volo.

Il terzo settore è quello dell'imballaggio dei semiconduttori elettronici. In questo settore, le apparecchiature di ispezione a raggi X sono utilizzate principalmente per ispezionare lo stato delle connessioni interne, la qualità delle saldature, i vuoti, le crepe e altri difetti dell'imballaggio dei chip per garantire le prestazioni elettriche e l'affidabilità del chip. Per i suoi valori, è caratterizzata dall'ispezione dei giunti di saldatura. Utilizzando la tecnologia di imaging a raggi X, è in grado di vedere chiaramente la forma e la qualità dei giunti di saldatura nel pacchetto, prevenendo i guasti elettrici causati da saldature scadenti. È inoltre in grado di ispezionare i difetti interni. Rileva le bolle e i vuoti che possono verificarsi durante il processo di confezionamento, prevenendo le rotture e i guasti causati dalla concentrazione di stress.

Il quarto settore è quello che tutti conosciamo e che utilizza ampiamente le macchine di ispezione a raggi X nella stessa linea di produzione, ovvero il settore SMT. L'SMT è uno dei processi principali della produzione elettronica. Le apparecchiature di ispezione a raggi X vengono utilizzate nel processo SMT per ispezionare i giunti di saldatura e la qualità dei componenti montati, garantendo la qualità dell'assemblaggio dei circuiti stampati. Per i suoi valori, è caratterizzata dall'ispezione della qualità dei giunti di saldatura.

L'apparecchiatura a raggi X è in grado di ispezionare efficacemente la qualità dei giunti di saldatura, come saldature eccessive o insufficienti, ponti e altri problemi, prevenendo così i guasti ai circuiti causati da difetti di saldatura. È inoltre in grado di rilevare vuoti e ponti. È in grado di identificare rapidamente i vuoti e i fenomeni di bridging all'interno dei giunti di saldatura, garantendo l'affidabilità e le prestazioni della scheda di circuito.

Il quinto settore è quello dei LED. Nella produzione dei LED, le apparecchiature di ispezione a raggi X vengono utilizzate per controllare l'imballaggio dei chip LED, le giunzioni di saldatura e le strutture interne per garantire l'efficienza luminosa, la durata e la coerenza dei prodotti LED. Per i suoi valori, l'apparecchiatura è caratterizzata dall'ispezione dell'imballaggio dei chip. L'apparecchiatura a raggi X è in grado di rilevare vuoti, crepe e qualità dei giunti di saldatura nell'imballaggio dei chip LED, per evitare un calo dell'efficienza luminosa e una riduzione della vita utile. È inoltre in grado di ispezionare i difetti interni. L'ispezione della struttura interna dei LED garantisce l'integrità e l'uniformità dell'imballaggio, migliorando così l'affidabilità e la coerenza dei prodotti LED.

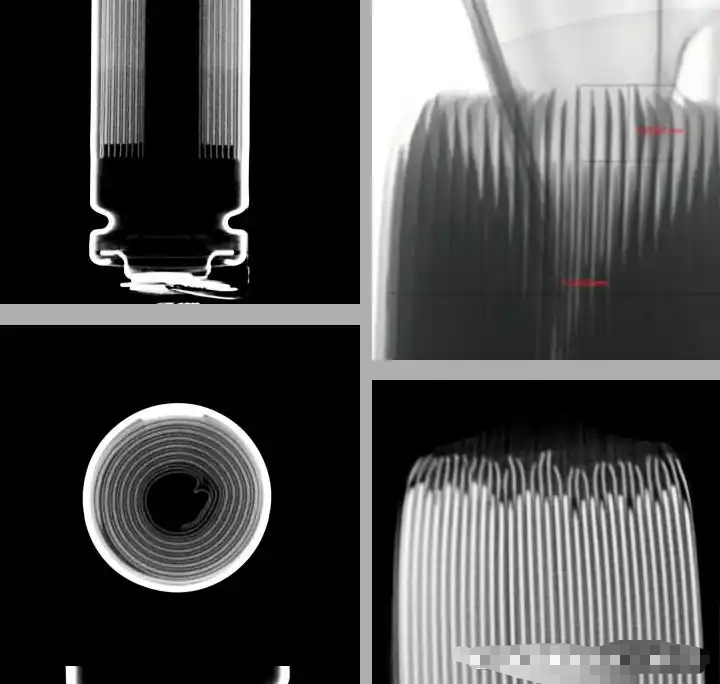

Il sesto settore è quello dei connettori e dei cavi. I connettori e i cavi sono componenti di connessione fondamentali nei dispositivi elettronici. Le apparecchiature di ispezione a raggi X vengono utilizzate per controllare la qualità della saldatura dei connettori, la struttura interna dei fili e l'integrità delle connessioni. Per i suoi valori, è caratterizzata dall'ispezione della qualità delle saldature. Si tratta di utilizzare la tecnologia a raggi X per ispezionare la qualità della saldatura dei connettori, garantendo l'affidabilità delle connessioni elettriche e prevenendo i guasti elettrici causati da un cattivo contatto. Inoltre, prevede l'ispezione del filo interno. Si tratta di individuare rotture, crepe e connessioni difettose dei fili interni per garantire la stabilità e la sicurezza della trasmissione del segnale.

Il settimo settore è quello delle batterie al litio. Le batterie al litio sono ampiamente utilizzate nei veicoli elettrici, nell'elettronica di consumo e in altri settori. L'apparecchiatura di ispezione a raggi X viene utilizzata per ispezionare i separatori, i fogli di elettrodi, i giunti di saldatura e l'integrità strutturale delle batterie per prevenire incidenti di sicurezza causati da difetti interni. Per i suoi valori, ha capacità di rilevamento della struttura interna. La tecnologia a raggi X è in grado di rilevare se i fogli di elettrodi all'interno della batteria sono avvolti correttamente, se il separatore si è spostato e se ci sono bolle, prevenendo così i cortocircuiti e le fughe termiche della batteria. Inoltre, è in grado di controllare la qualità dei giunti di saldatura. Rileva la qualità dei giunti di saldatura delle connessioni della batteria per garantire che siano saldati in modo sicuro e per evitare guasti alla batteria dovuti a giunti di saldatura scadenti.

L'ottava e ultima industria è quella delle capacità. Nei circuiti elettronici, i condensatori sono importanti componenti di accumulo di energia. Le apparecchiature di ispezione a raggi X vengono utilizzate per ispezionare la struttura interna, i giunti di saldatura e la qualità dell'imballaggio dei condensatori, per garantirne il funzionamento affidabile nei circuiti. Per i suoi valori, è dotata di un sistema di rilevamento dei difetti interni. Si tratta di utilizzare il rilevamento a raggi X per verificare la presenza di eventuali difetti come vuoti, crepe e delaminazioni all'interno del condensatore, evitando così che il guasto del condensatore influisca sulle prestazioni del circuito. È inoltre dotato di un sistema di rilevamento dell'imballaggio. Si tratta di garantire la tenuta e l'integrità dell'imballaggio del condensatore per evitare il degrado delle prestazioni causato da fattori ambientali.

In conclusione, le apparecchiature di ispezione a raggi X sono uno strumento importante nel campo dei test senza perdite e svolgono un ruolo indispensabile nei settori high-tech come le comunicazioni 5G, l'aerospaziale, l'imballaggio di semiconduttori elettronici, SMT, LED, connettori, fili, batterie al litio e condensatori. D'altra parte, sono cruciali in tutti i settori perché garantiscono la qualità, la sicurezza e la conformità dei prodotti rilevando difetti interni, contaminanti o difetti strutturali senza danneggiare gli articoli. Nel settore alimentare e farmaceutico, identificano oggetti estranei o incongruenze, mentre nel settore manifatturiero ed elettronico verificano l'integrità dei componenti e l'accuratezza dell'assemblaggio. Nel settore della sicurezza e dell'aerospaziale, migliorano la sicurezza scoprendo minacce nascoste o debolezze dei materiali. L'imaging ad alta precisione e senza perdite aiuta a mantenere gli standard industriali, a ridurre i rischi e a migliorare l'efficienza.