LED SMT Reflow Soldering Defect Evaluasi Inspeksi Sinar X sangat penting karena mendeteksi cacat sambungan solder yang tersembunyi, seperti lubang, retakan, solder yang tidak mencukupi, atau komponen yang tidak sejajar, sehingga memastikan bahwa cacat tersebut tidak terlihat oleh inspeksi optik. Dengan memastikan sambungan solder yang tepat, hal ini meningkatkan keandalan LED, mencegah kegagalan dini, dan mempertahankan kinerja yang konsisten dalam aplikasi pencahayaan dan tampilan. Metode pemeriksaan non-destruktif ini meningkatkan kualitas produksi, mengurangi pengerjaan ulang yang mahal, dan membantu memenuhi standar industri untuk rakitan elektronik. Dalam bab ini, kami ingin membahas lebih dalam dan memberikan penjelasan singkat tentang cacat penyolderan SMT LED yang umum terjadi.

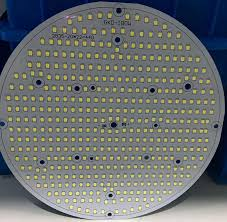

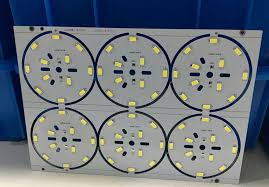

Cacat pertama adalah persentase rongga penyolderan. Rongga ini sering terbentuk pada lapisan solder chip LED. Hal ini disebabkan oleh ekspansi udara atau senyawa fluks yang terperangkap dalam solder selama proses pemanasan dalam oven reflow. Keandalan sambungan solder tidak hanya bergantung pada paduan solder, tetapi juga pada pelapisan logam perangkat LED dan PCB. Selain itu, profil waktu dan suhu dari proses penyolderan reflow secara signifikan berdampak pada kinerja sambungan solder bebas timbal, karena hal ini memengaruhi sifat pembasahan dan struktur mikro sambungan solder. Dibandingkan dengan solder timah-timah, solder bebas timah lebih rentan terhadap kegagalan getas pada sambungan karena tekanan termal dan retakan fatik yang disebabkan oleh siklus suhu. Mesin inspeksi sinar-X Nectec, seperti NX-EF, dapat menggunakan metode pengujian non-destruktif untuk menguji rasio kekosongan pada sambungan solder setelah penyolderan reflow SMT, menghilangkan produk yang cacat, memastikan bahwa panas dari manik-manik lampu dihantarkan dengan sempurna ke substrat aluminium, dan dengan demikian memastikan masa pakai lampu memenuhi persyaratan desain.

Salah satu penyebab kekosongan penyolderan adalah rasio kekosongan yang terlalu tinggi. Dalam lingkungan pengujian kejut termal, ekspansi termal dan kontraksi gelembung dapat menyebabkan keretakan solder, sehingga mengurangi keandalan chip LED. Hal ini secara langsung menyebabkan masalah seperti peningkatan resistensi termal dan berkurangnya konduktivitas termal karena rasio kekosongan yang tinggi. Untuk chip LED dengan bantalan yang lebih besar, rasio kekosongan yang tinggi memainkan peran utama dalam mempengaruhi pembuangan panas. Semakin tinggi rasio kekosongan, semakin besar resistansi termal, dan semakin buruk kinerja pembuangan panas.

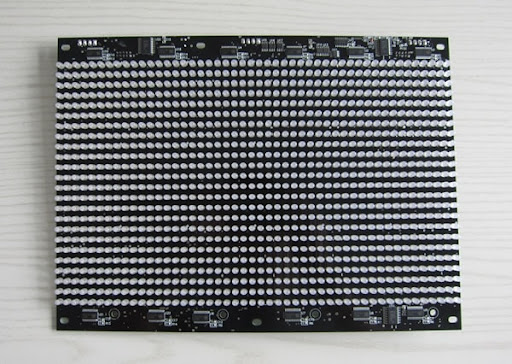

Cacat kedua adalah bola solder. Papan sirkuit elektronik memiliki kepadatan komponen yang tinggi dan jarak yang kecil, yang dapat menyebabkan bola solder jatuh saat digunakan. Alasan di balik hal ini adalah karena bola solder adalah bola solder kecil yang tidak diinginkan yang dapat terbentuk karena pasta solder yang berlebihan, profil aliran balik yang tidak tepat, atau kontaminasi. Bola solder liar ini menimbulkan risiko yang signifikan terhadap komponen chip, karena dapat menyebabkan korsleting dengan menjembatani jejak atau pin konduktif yang berdekatan, terutama pada desain PCB dengan kepadatan tinggi. Selain itu, bola-bola ini dapat menyebabkan kebocoran listrik, gangguan sinyal, atau bahkan kegagalan komponen jika berpindah tempat selama pengoperasian. Pada rakitan dengan nada halus atau miniatur, seperti paket LED atau IC, bola solder juga dapat menimbulkan tekanan mekanis atau mengganggu pembuangan panas yang tepat, yang selanjutnya membahayakan keandalan. Kehadiran mereka sering kali menunjukkan kontrol proses yang buruk, yang memerlukan tindakan korektif dalam desain stensil, aplikasi pasta solder, atau parameter aliran balik untuk mencegah masalah kinerja jangka panjang. Di sisi lain, masalah keselamatan pekerja sangat dibutuhkan.

Bola solder dapat menimbulkan risiko serius bagi pekerja selama penanganan dan perakitan PCB. Jika bola logam kecil ini tersebar di seluruh ruang kerja, bola tersebut dapat terhirup secara tidak sengaja atau bersentuhan dengan kulit, sehingga berpotensi menyebabkan iritasi pernapasan atau reaksi alergi akibat timbal atau residu fluks. Selain itu, bola solder di lantai dapat menimbulkan bahaya terpeleset, sementara bola solder yang terperangkap di peralatan dapat menyebabkan korsleting listrik atau percikan api, sehingga meningkatkan risiko luka bakar atau kebakaran. Dalam produksi bervolume tinggi, paparan berulang terhadap percikan solder juga dapat menimbulkan masalah keselamatan di tempat kerja dalam jangka panjang.

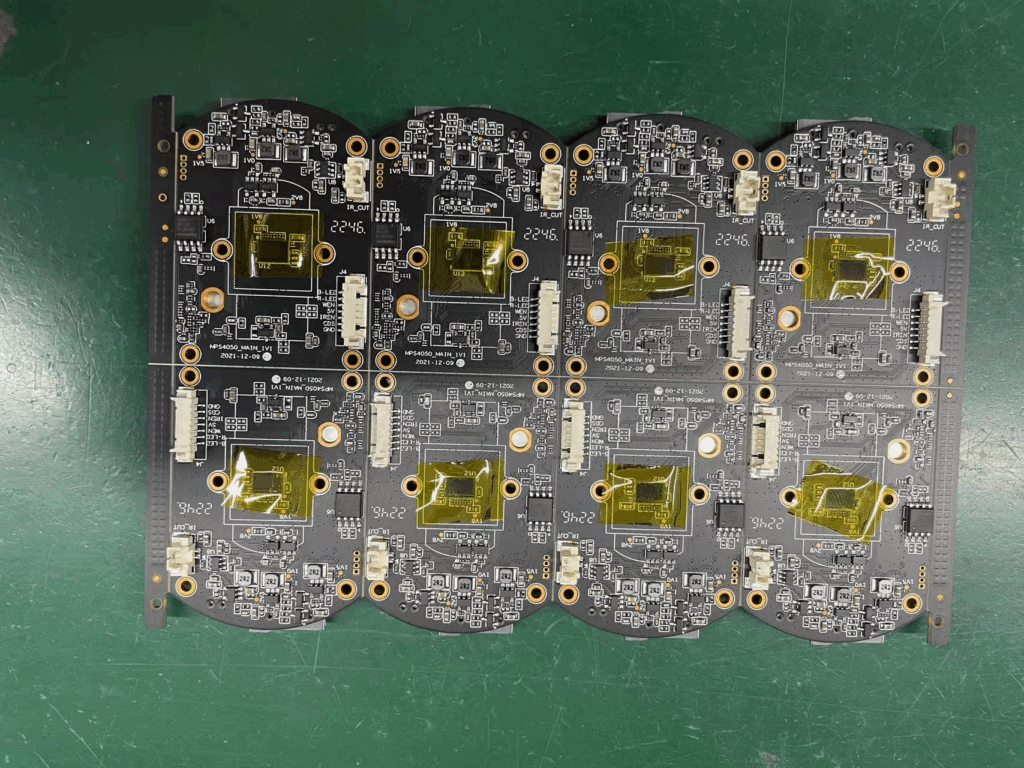

Cacat ketiga dibagi menjadi penyolderan palsu, penyolderan dingin, penyolderan kosong, dan masalah penyolderan virtual. Untuk penyolderan salah, hal ini terjadi ketika solder tampak membentuk sambungan tetapi tidak memiliki ikatan metalurgi yang tepat karena kontaminasi, seperti oksidasi dan residu fluks, atau panas yang tidak memadai. Akibatnya, sambungan solder mungkin terlihat dapat diterima tetapi gagal di bawah tekanan atau pengujian listrik; Untuk penyolderan dingin, ini terjadi ketika solder tidak sepenuhnya meleleh selama aliran balik, menghasilkan sambungan yang tumpul, berbintik-bintik, atau retak. Hal ini disebabkan oleh suhu reflow yang tidak mencukupi, pemanasan yang tidak merata, atau pendinginan dini, yang menyebabkan sambungan mekanis dan elektrik yang lemah; Untuk penyolderan kosong, hal ini terjadi ketika ada sambungan solder yang hilang atau tidak lengkap di mana solder gagal membasahi pad atau timah komponen dengan benar. Hal ini dapat terjadi karena aplikasi pasta solder yang buruk, ketidaksejajaran, atau kontaminasi pad, meninggalkan celah pada sambungan; Terakhir untuk penyolderan virtual, hal ini terjadi ketika sambungan terputus-putus, seperti terkadang berfungsi, terkadang gagal. Hal ini biasanya disebabkan oleh retakan mikro, pembasahan yang buruk, atau tekanan mekanis.

Sering kali, proses ini lolos dalam pengujian awal, tetapi gagal dalam getaran atau siklus termal. Yang membuat masing-masing dapat dibedakan adalah bahwa penyolderan palsu melibatkan ikatan yang terlihat tanpa adhesi yang sebenarnya, sedangkan penyolderan dingin dihasilkan dari peleburan yang tidak memadai, menciptakan sambungan yang rapuh. Penyolderan kosong berarti tidak ada bahan solder, sedangkan penyolderan virtual adalah sambungan yang tidak stabil yang sesekali gagal. Penyolderan dingin dan penyolderan palsu sering kali terkait dengan proses, seperti masalah panas atau kontaminasi, sedangkan penyolderan kosong berasal dari pengendapan pasta atau kesalahan penempatan. Penyolderan virtual sangat berbahaya karena dapat tidak terdeteksi hingga terjadi kegagalan di lapangan.

Cacat keempat juga dapat dibagi menjadi masalah sambungan solder dingin, bridging, dan tombstoning. Kami akan membahas bagian ini dengan menggunakan studi kasus nyata. Sebagai permulaan, salah satu pelanggan Nectec sebelumnya meminta Nectec untuk menguji rasio kekosongan, khususnya untuk mengamati hasil penyolderan pasta solder setelah penyolderan reflow. Kami memeriksa kemasan LED menggunakan pencitraan sinar-X waktu nyata dan menemukan sejumlah besar lubang solder, dengan rasio kekosongan bantalan pembuangan panas melebihi 30% dalam semua kasus. Dibandingkan dengan solder yang mengandung timbal, solder bebas timbal lebih rentan terhadap kegagalan sambungan rapuh yang disebabkan oleh aliran termal dan retakan fatik akibat perputaran suhu. Rasio kekosongan solder yang terlalu tinggi mengurangi keandalan chip LED, yang menyebabkan ekspansi termal dan kontraksi gelembung selama pengujian kejut termal, yang menyebabkan keretakan solder.

Secara kebetulan, pelanggan lain dari Nected menghubungi kami melalui email pada suatu hari untuk melaporkan bahwa produk mereka memiliki insiden piksel mati yang tinggi, dengan probabilitas melebihi 38%, dan meminta kami untuk memberikan laporan analisis kepada mereka. Setelah mengesampingkan serangkaian masalah, seperti driver, berat heat sink, luas permukaan heat sink, perekat termal, konduktivitas termal substrat aluminium, dan apakah sirkuit mengalami korsleting, kami masih belum dapat mengidentifikasi penyebab dead pixel. Setelah menganalisis situasinya, kami menemukan bahwa lapisan solder dari proses penyolderan reflow belum diuji. Kami kemudian melakukan pemeriksaan sinar X non-destruktif dan menemukan bahwa lapisan solder di belakang LED yang terbakar memiliki rongga, dengan area rongga pada umumnya mencapai lebih dari 25% area pad. Contoh lain melibatkan klien pencahayaan Nectec yang melaporkan bahwa masalah pembuangan panas LED mereka masih belum terselesaikan. Setelah melakukan pemeriksaan sinar X, kami menemukan bahwa rasio porositas las pada produk mereka mencapai 40%, dengan semua sampel yang diuji menunjukkan rasio porositas yang melebihi 10%. Di antara sampel tersebut, 37% memiliki rasio void antara 20% dan 30%, 42% memiliki rasio void antara 30% dan 40%, dan 12% memiliki rasio void di atas 40%, yang cukup mengkhawatirkan. Setelah menerapkan rencana perbaikan kami, produk mereka mempertahankan rasio void di bawah 10% selama penyolderan reflow, dan pelanggan sangat puas.