Saat ini, produk pencahayaan LED perlahan-lahan telah mendapatkan pengakuan pasar di seluruh dunia karena karakteristiknya yang ramah lingkungan, hemat energi, dan hemat biaya. Lampu pijar perlahan-lahan mulai ditinggalkan dan digantikan oleh lampu LED. Industri LED telah menjadi pelopor dalam memecahkan masalah energi dan lingkungan, dan pasar pencahayaan LED telah berkembang pesat. Ekspansi yang cepat dari pasar ini tidak diragukan lagi telah mendorong kemajuan pesat industri mesin pemasangan chip LED dan peralatan produksi. Pada artikel ini kita akan menyelami lebih dalam hubungan antara industri LED dan teknologi SMT yang sesuai yang dirancang khusus untuknya.

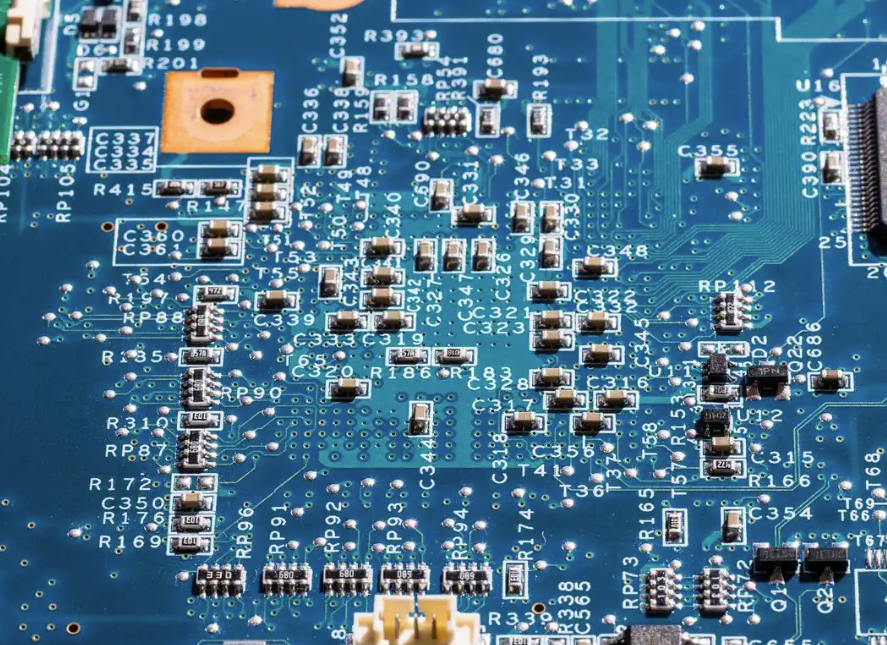

Pertama, mari kita bahas tentang sebagian keuntungan teknologi pemasangan SMT dan bagaimana hal ini secara langsung berdampak pada pembuatan lampu LED. Pertama, komponen perakitan dengan kepadatan tinggi memungkinkan miniaturisasi dan desain produk elektronik yang ringan. Teknologi SMT memungkinkan komponen dirakit dengan kepadatan yang lebih tinggi, sehingga secara signifikan mengurangi ukuran dan berat produk elektronik. Keunggulan ini tidak hanya meningkatkan portabilitas produk tetapi juga membantu mengurangi biaya dan mendorong inovasi. Misalnya, ia memiliki otomatisasi tingkat tinggi, yang secara signifikan meningkatkan efisiensi produksi; Keandalan yang luar biasa dan teknologi produksi otomatisnya memastikan sambungan yang aman di setiap sambungan solder, sementara desain tanpa timah atau timah pendek perangkat pemasangan permukaan (SMD), dikombinasikan dengan pemasangan yang aman di permukaan PCB, memberikan keandalan yang tinggi dan ketahanan getaran yang kuat; Performa frekuensi tinggi yang unggul yang tidak hanya meminimalkan dampak karakteristik terdistribusi, tetapi juga secara signifikan mengurangi kapasitansi parasit dan induktansi parasit antar-timah melalui pemasangan yang aman di permukaan PCB. Ini sangat mengurangi interferensi elektromagnetik (EMI) dan interferensi frekuensi radio (RFI), yang secara efektif meningkatkan kinerja frekuensi tinggi; Penghematan biaya dan karena teknologi SMT meningkatkan kepadatan perutean PCB, ini mengurangi jumlah lubang bor dan area PCB, dan menyederhanakan jumlah lapisan untuk PCB dengan fungsi yang sama. Faktor-faktor ini secara kolektif menurunkan biaya produksi PCB. Selain itu, desain SMC/SMD tanpa timbal atau timbal pendek menghemat bahan timbal dan menghilangkan proses seperti pemotongan dan pembengkokan kawat, yang selanjutnya mengurangi biaya peralatan dan tenaga kerja. Peningkatan kinerja frekuensi tinggi juga mengurangi biaya debugging RF. Pengurangan ukuran dan berat produk elektronik, bersama dengan keandalan penyolderan yang ditingkatkan, semuanya berkontribusi untuk menurunkan biaya sistem secara keseluruhan.

Kedua, pertama-tama kami akan memberikan penjelasan singkat mengenai proses pembuatan SMT standar dan kemudian membandingkannya dengan pembuatan SMT LED pada langkah berikutnya. Peralatan inti dari lini produksi SMT meliputi printer, mesin pengeluaran, mesin penempatan, dan oven reflow atau mesin penyolderan gelombang. Dengan kemajuan teknologi pemasangan di permukaan, khususnya penggunaan paket sirkuit terpadu timah bawah yang meluas seperti BGA dan QFN, keterbatasan penyolderan gelombang menjadi semakin jelas. Akibatnya, proses arus utama kini telah bergeser ke penyolderan reflow. Dari perspektif yang lebih baik, model paling dasar dari mesin pick-and-place mencakup bingkai, mekanisme penjepitan papan sirkuit, pengumpan, kepala pick-and-place, nosel, dan sumbu X, Y, dan Z. Di antaranya, sumbu Z didesain secara cerdas. Sumbu ini tidak hanya dapat bergerak naik dan turun sepanjang arah Z, tetapi juga berputar pada arah θ. Desain ini secara cerdik memecahkan masalah penyesuaian sudut rotasi apabila komponen menyimpang dari pad solder.

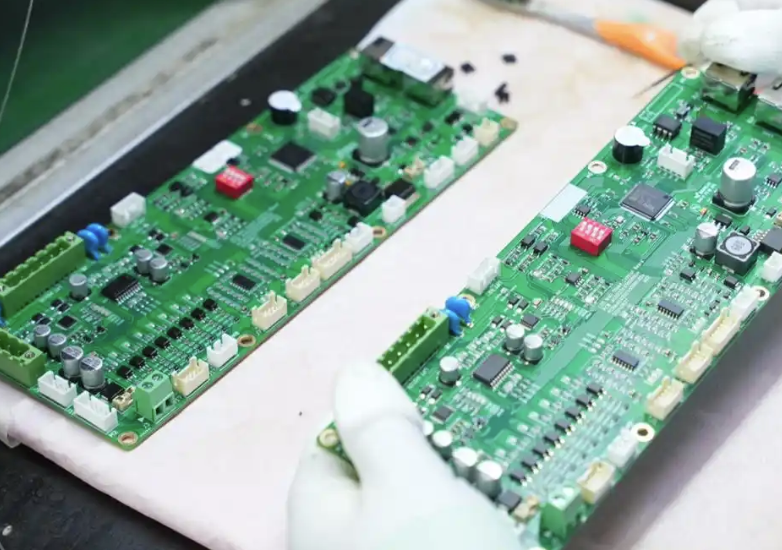

Ketiga, mari kita bandingkan mesin pick and place SMT standar dengan mesin pick and place LED. Dudukan chip LED adalah peralatan pemasangan SMT yang disesuaikan untuk industri LED, yang dirancang untuk mencapai perakitan papan sirkuit LED volume besar yang efisien. Alat ini membutuhkan presisi sedang tetapi kecepatan tinggi. Ini adalah perangkat otomatis yang sangat terintegrasi dan presisi tinggi yang dikontrol dengan presisi oleh komputer. Ini mengintegrasikan teknologi mekanik, optik, dan listrik dan mencakup bingkai, mekanisme konveyor PCB, sistem pemosisian penggerak dan servo, kepala penempatan, pengumpan, sistem pengenalan optik, sensor, dan sistem kontrol komputer. Melalui serangkaian operasi yang kompleks, seperti pengisapan, pemindahan, pemosisian, dan penempatan, ia dapat dengan cepat dan akurat memasang komponen SMD ke papan PCB.

Tidak hanya itu, mesin pick and place LED terutama dioptimalkan untuk akurasi penempatan chip LED seperti 3014, 2835, 3528, 5050, 5630, dan 5730. Meskipun akurasi pemrosesannya lebih rendah daripada mesin penempatan tradisional, mesin penempatan LED lebih menekankan pada kinerja, terutama stabilitas mesin, kecepatan pengoperasian, kemudahan pengoperasian, dan kontrol ukuran. Berikut ini beberapa fakta mengenai mengapa mesin pick and place LED sedang dalam tren peningkatan: (1). Dudukan chip khusus LED telah mengadopsi teknologi cerdas secara luas dan dilengkapi dengan sensor berkinerja tinggi untuk mengumpulkan data operasional secara real time dan mengirimkannya ke komputer untuk diproses, sehingga memastikan stabilitas dan keandalan proses pemasangan; (2). Kecepatan penempatan dudukan chip LED harus mencapai setidaknya 18.000 titik per jam untuk memenuhi tuntutan produksi yang efisien. NT-L12 Nectec dapat dengan mudah melampaui persyaratan ini dengan kecepatan penempatan yang mengesankan yaitu 7000 CPH; (3). Metode pengoperasian yang sederhana, mudah dipahami, dan mudah digunakan dapat secara signifikan memperpendek siklus pelatihan staf, mengurangi kesalahan operasional dalam produksi, dan dengan demikian meningkatkan efisiensi produksi dan kualitas produk; (4). Dudukan chip LED harus mampu memasang papan PCB dengan panjang minimal 1200 mm untuk memenuhi permintaan papan PCB yang panjang pada produk lampu LED. NT-L12 Nectec juga dapat dengan mudah melampaui persyaratan ini dengan ukuran PCB yang didukung hingga 1200mm.