With the vision of empowering and building an intelligent robot ecosystem, Nectec has been committed to creating high-quality, intelligent robot products and services to meet the diverse needs of industry customers. To this end, Nectec has established its own high-end SMT chip production line, starting from the source, striving for excellence, and ensuring the efficiency, high quality and reliability of its products. The SMT chip production line has the advantages of high automation, high precision, high consistency and high standard quality control. It can effectively improve production efficiency, improve product quality, and provide strong support for the innovation of core components of intelligent robots in the industry. This is crucial to quickly respond to market demand, shorten product time-to-market, and ensure high quality and performance of the drone’s core components.

First, we want to introduce Nectec‘s production line. The idea circles around the integrated mounting and inspection system to achieve high efficiency and high-quality process production. At the beginning of 2025, Nectec actively deployed and built a high-end SMT wiring line. The patch line introduces ELT and Faroad high-end models, and successfully builds an integrated system for mounting and inspection. The application of this system has brought remarkable results, greatly improved production efficiency, and greatly improving product quality. Through this investment measure, Nectec has effectively ensured the efficient production of core components of intelligent robots and won important advantages in market competition.

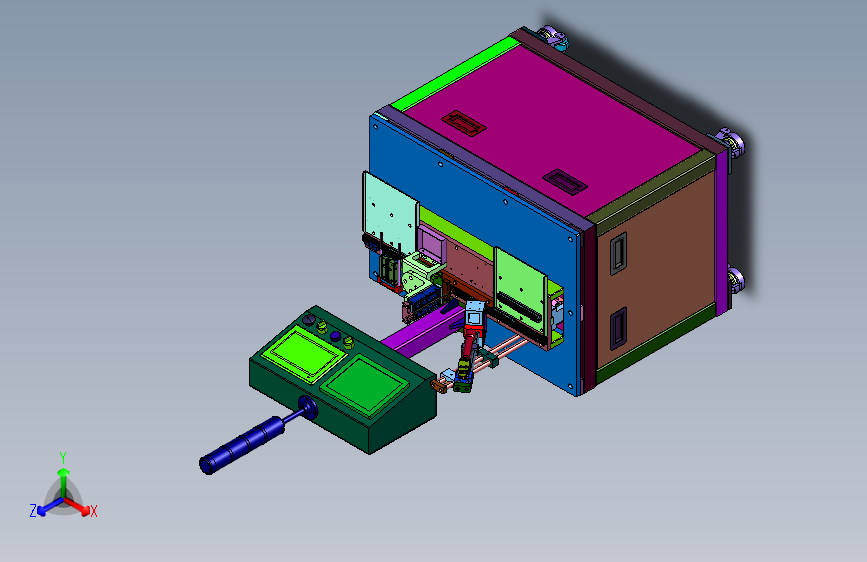

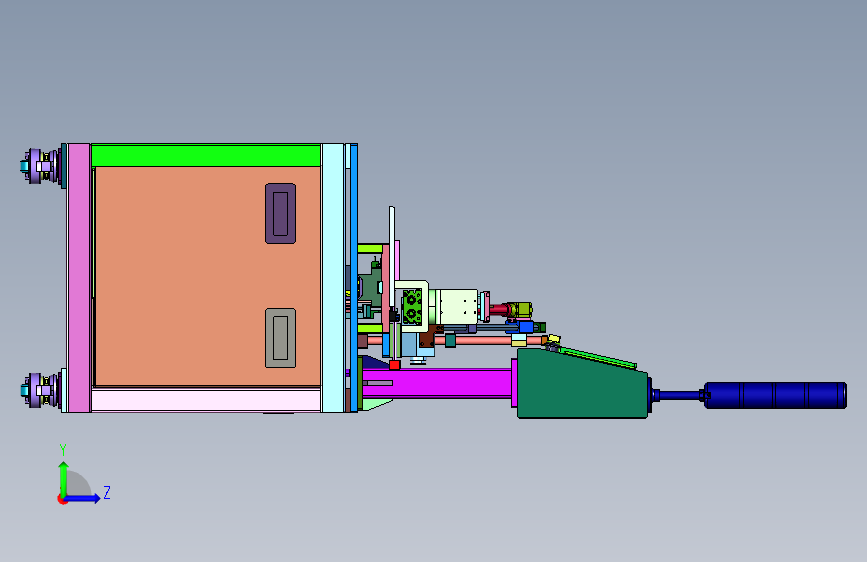

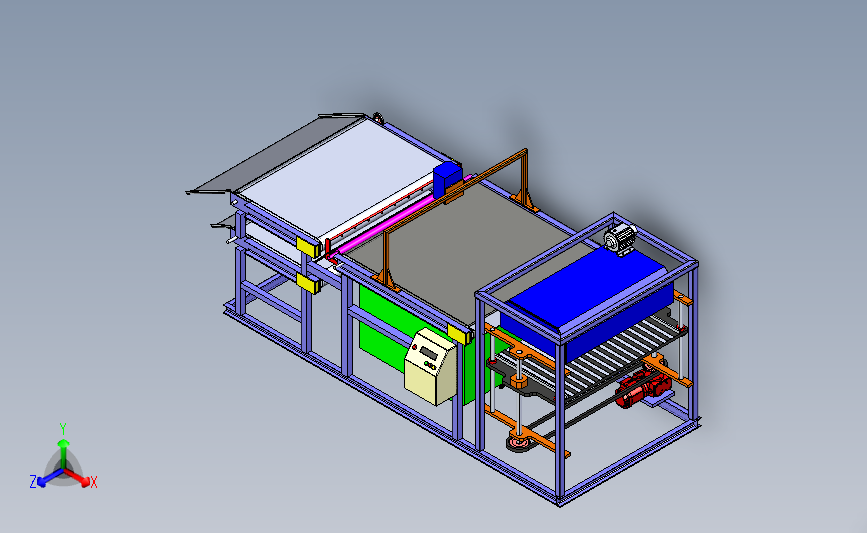

Second, we want to explain the idea that high-standard production processes can break through high-precision chip mounting process problems. During the production process, Nectec strictly follows high-standard production processes and successfully breaks through the problem of high-precision chip mounting technology. First of all, high-precision fully automatic solder pastes printing equipment: ensures even distribution of solder paste and high-precision printing, and improves welding quality from the source. The specific representative product is Nectec’s SP-510A Automatic Stencil Printer; the second one is a wide-coverage, high-precision SMT component patch: 03015 (0.3mm*0.15mm) components can be printed to ensure the accuracy of the patch and meet diverse production needs. The specific representative product is Nectec’s NT-T5 High Speed Pick and Place Machine; the third one is the PID closed-loop control of twelve temperature zone nitrogen reflow soldering: by accurately controlling the temperature curve, the stability and reliability of the welding process are ensured. The specific representative product is RO-1200 Lead Free Reflow Oven; Nectec has these advanced equipment and technologies to ensure that higher standards of process requirements can be met during the production process and provide a strong guarantee for the production of high-quality core components of intelligent robots.

Third, we want to talk about how Nectec focuses on strict quality control and quality control, and multiple quality inspection links ensure product quality. Nectec strictly controls every production process and uses multiple quality inspection methods to ensure the quality of every product.

First of all, 3D online AOI technology: Through 3D multi-dimensional inspection, it accurately identifies the mounting quality and welding status of components to ensure the perfection of each part; the second is the first-piece testing technology: the test accuracy is as high as 0.05%, ensuring that the first product in each production batch meets the quality standards. Through strict quality control, Nectec ensures the high reliability and high performance of its products in the market, providing customers with trustworthy products and services.

Fourth, we want to discuss Nectec‘s future prospect and business envisioning plans, especially on serving five independent product lines to achieve self-control of delivery time. Through independent production, Nectec has successfully achieved self-control of the delivery time of its five major product lines, effectively ensuring timely supply of products and rapid response to the market. Nectec’s current independent production line covers every step of the SMT wiring line from solder paste printing, SMT mounting, intermediate inspection, reflow soldering, after-furnace inspection, performance testing to rework, and strictly controls the production of key components in each production line. For example, AI tracking modules, large four-axis shafts, drone power sleeves, etc. use nano-material steel mesh to ensure the tinning effect; use full-section nitrogen reflow welding to ensure the welding and tin-climbing effect; and use fully automatic 3D AOI to ensure no defective products flow out.

To conclude, with its excellent technical strength and strict quality control, Nectec has established a strong brand influence in the field of smart SMT mounters. By building its own high-end SMT mounter production line, Nectec will further optimize the production process, ensure the high quality and high performance of core components, and help intelligent SMT mounter technology reach a new level. In the future, Nectec will continue to increase investment in research and development to promote the continuous advancement of intelligent robot technology.