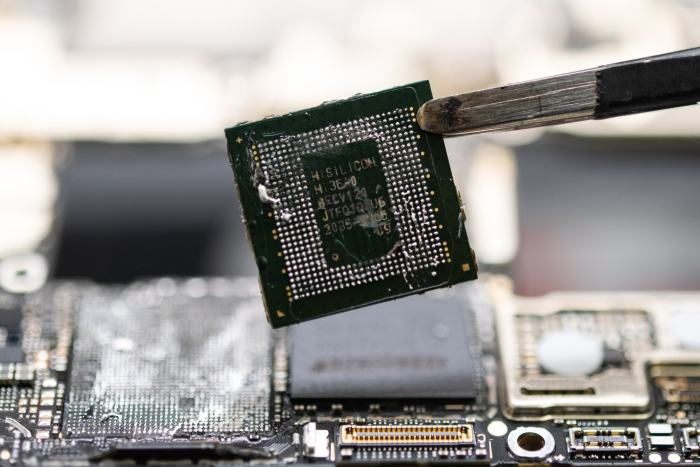

En este capítulo se tratará un tema único: cómo mejorar la eficacia de las máquinas de colocación SMT. Las máquinas de colocación SMT no sólo deben ser rápidas, sino también precisas y estables. Sin embargo, en el funcionamiento real, cada máquina de colocación SMT tiene diferentes especificaciones para los componentes electrónicos y velocidades variables. Por ejemplo, los componentes LED tienen requisitos de precisión relativamente menores en comparación con los componentes SMT, por lo que los productos LED pueden colocarse más rápido que los productos SMT. Esto se debe a que la colocación SMT requiere mayor precisión que la colocación LED, y cuando se colocan componentes electrónicos de alta precisión, la máquina de colocación‘La velocidad de procesamiento se ralentiza, lo que reduce la eficacia de la colocación. Uno de los problemas de las boquillas de las máquinas pick-and-place es la presión de vacío insuficiente. Antes de recoger los componentes, la válvula mecánica del cabezal de colocación cambia automáticamente de soplado de aire a aspiración de vacío, creando un cierto nivel de presión negativa. Cuando el sensor de presión negativa detecta un valor dentro de un rango determinado después de recoger el componente, la máquina funciona con normalidad; de lo contrario, la succión es insuficiente. Por un lado, puede haber fugas de presión en el circuito de suministro de aire, como envejecimiento o rotura de los tubos de aire de goma, envejecimiento o desgaste de las juntas, o desgaste de la boquilla tras un uso prolongado. Por otro lado, los adhesivos o el polvo del entorno externo, especialmente la gran cantidad de residuos generados tras cortar componentes empaquetados con cinta de papel, pueden provocar la obstrucción de la boquilla de la máquina pick-and-place. Los errores en los ajustes del programa de la máquina pick-and-place también pueden reducir la eficacia de colocación de la máquina. La solución es que el fabricante de la máquina pick-and-place proporcione al cliente información precisa y concisa sobre el funcionamiento del producto. Otro factor es la calidad de los propios componentes electrónicos.

Cuando la boquilla recoge y coloca componentes electrónicos, si las clavijas no están totalmente insertadas, están dobladas o rotas, esto sólo puede controlarse garantizando la calidad de los componentes adquiridos. Esto no sólo afecta a la eficacia de la colocación y a la calidad del producto, sino que también provoca diversos grados de daños en la boquilla cuando ésta recoge y coloca repetidamente dichos componentes, lo que acaba reduciendo la vida útil de la boquilla. Una línea de montaje SMT suele incluir una máquina de colocación de alta velocidad y una máquina de colocación de alta precisión. La primera se encarga principalmente de los componentes de montaje superficial, mientras que la segunda se centra en los circuitos integrados y los componentes de forma irregular. Cuando ambas máquinas consiguen tiempos de colocación iguales y mínimos, toda la línea de montaje SMT alcanza la máxima capacidad de producción. Por tanto‘s profundizan en el orden recomendado de montaje de los componentes de chip para lograr una eficacia óptima en las máquinas SMT pick and place.

En primer lugar, el equilibrado de la carga. La secuencia y el principio generales consisten en asignar razonablemente el número de componentes que deben montarse en cada máquina SMT, de modo que el tiempo de montaje de cada máquina sea lo más equitativo posible. Al asignar inicialmente el número de componentes que deben montarse en cada máquina, suele haber una gran diferencia en el tiempo de montaje. Esto requiere ajustar la carga de producción de todas las máquinas de la línea de producción en función del tiempo de montaje de cada máquina, y transferir algunos de los componentes de las máquinas con tiempos de montaje más largos a otras máquinas para lograr el equilibrio de la carga.

En segundo lugar, la optimización de los equipos SMT. La optimización de los programas CNC de cada equipo consiste en garantizar que las máquinas de pick-and-place funcionen con la mayor eficacia posible durante la producción, consiguiendo así una colocación extremadamente rápida y reduciendo el tiempo de colocación de los equipos. Los principios de optimización dependen de la estructura del equipo. Algunos principios pueden entrar en conflicto durante la optimización del programa, lo que requiere un compromiso para seleccionar la solución óptima. Se puede utilizar software de optimización para la distribución de cargas y la optimización de equipos, que incluye programas de optimización de equipos y software de equilibrado de líneas de producción. Los programas de optimización de equipos se centran principalmente en optimizar los programas de colocación y las configuraciones de los alimentadores. Tras obtener la lista de materiales de los componentes y los datos CAD, pueden generarse programas de colocación y tablas de configuración de alimentadores. El programa de optimización optimiza las rutas de movimiento de los cabezales de colocación y las configuraciones del alimentador para minimizar la distancia de movimiento de los cabezales de colocación, ahorrando así tiempo de colocación. El software de equilibrado de la línea de producción es una herramienta eficaz para optimizar toda la línea de producción. El software de optimización emplea algoritmos de optimización específicos, y el software de optimización actual ha alcanzado un cierto nivel de inteligencia, lo que le permite completar el proceso de optimización con mayor rapidez y eficacia.

En tercer lugar, eliminar los cuellos de botella. Una cadena de montaje SMT consta de varias máquinas automatizadas. Si una máquina funciona más despacio que las demás, se convierte en el cuello de botella que limita la velocidad global de la línea de producción SMT. Los cuellos de botella suelen producirse en las máquinas de colocación, y la única forma de eliminarlos es añadiendo más máquinas de colocación. En la mayoría de los casos, los clientes optan por una máquina de colocación multifunción de alta velocidad, ya que combina las características de las máquinas de alta velocidad y las de alta precisión.

Puede manipular la gama de componentes que abarcan tanto las máquinas de colocación de alta precisión como las de alta velocidad, resolviendo así los cuellos de botella causados por cualquiera de los dos tipos de máquinas. La tendencia actual en el desarrollo de máquinas de colocación también se alinea con esta dirección para satisfacer las demandas del mercado. Añadir una máquina de colocación a la línea de producción puede resolver los cuellos de botella y acelerar los ritmos de producción. Este enfoque proporciona una mayor capacidad de producción y más posiciones de alimentación, equilibrando mejor la línea de producción sin aumentar significativamente la complejidad de la gestión de la línea de producción. El resultado es un aumento mucho mayor de la capacidad de producción que la simple adición de una sola máquina de colocación.

En cuarto lugar, aplicar medidas de gestión estrictas y eficaces. Los equipos SMT son máquinas de precisión que integran sistemas mecánicos y eléctricos. La aplicación de medidas de gestión estrictas y eficaces durante el funcionamiento es un método importante para mejorar la eficiencia de la producción de la línea de montaje SMT. Por ejemplo, podemos precargar los componentes a reponer en alimentadores de repuesto. Mientras ensamblamos las últimas unidades del lote anterior en la línea de producción, también podemos preparar el siguiente lote de productos. Las líneas de montaje SMT son líneas de producción a gran escala en las que la producción se calcula en segundos. La fluidez de la producción y la calidad del producto dependen no sólo de los equipos y los factores ambientales, sino también en gran medida de los factores humanos. Si los operarios están muy familiarizados con el equipo, pueden resolver los problemas más rápidamente durante la producción, lo que ahorra tiempo de producción y mejora la eficacia. Por lo tanto, también debe darse prioridad a la formación de los empleados. Las inspecciones y el mantenimiento periódicos de los equipos SMT también son esenciales para garantizar su rendimiento óptimo. Por lo tanto, es crucial realizar inspecciones científicas y mantenimiento de los equipos de forma regular para mantenerlos en buen estado.

En conclusión, el aumento de la eficiencia de las máquinas de pick and place SMT en una línea de producción es crucial porque repercute directamente en la productividad, la rentabilidad y la calidad del producto. Una mayor eficacia significa una colocación más rápida de los componentes, una reducción de los tiempos de ciclo y un aumento del rendimiento, lo que permite a los fabricantes satisfacer la creciente demanda y acortar los plazos de entrega. También minimiza los errores, reduce el desperdicio de material y disminuye los costes operativos al optimizar la utilización de la máquina y el consumo de energía. Además, la mejora de la eficiencia aumenta la uniformidad del ensamblaje, lo que garantiza una mayor fiabilidad y rendimiento de los productos electrónicos. En un sector tan competitivo, maximizar la eficiencia de las máquinas SMT es clave para mantener la rentabilidad y seguir a la cabeza del mercado.