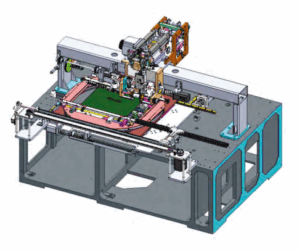

NI-H30 | Super Series Axial Component Insert Machine

The NI-H30 Super Series Axial Component Insert Machine (HA30S series horizontal component insertion machine) is a core product of the composite vertical and horizontal through-hole component insertion system solution. It focuses on meeting the personalized and diversified mass production needs in electronic manufacturing, and is compatible with surface mount production lines (SMT) and special processes such as selective soldering and through-hole reflow. It can achieve seamless integration, reduce uncontrollable factors such as manpower and defect rate, and improve productivity.

NI-H30 | Super Series Axial Component Insert Machine

- Beschreibung

Beschreibung

The new piezoelectric detection sensor improves the production quality and production efficiency.

Through piezoelectric sensor detection,the simple short-circuit detection method is changed, and the problems of detection misjudgment and pin blockage are effectively solved. Greatly improve the stability of the machine,improve the production capacity o the equipment.

The latest innovation 360 °servo rotation platform, realized 100% 360 °seamless insertion.

With the optional new free rotation platform, you can easily realize the process requirements of 360’insert at any angle, greatly reducing the process bottieneck and manual intervention. This innovative structure makes HA /MA series the most adaptable Axial insert machine in the industry.

Electric smart Feeder. The newly developed inteligent modular electric feeder has low noise,fast response,more reasonable structure and less failure rate.Efficient production at the highest level of area. You can also expand up to 80 stations to meet future process needs.

Spezifikation

Artikel | NI-H30 | NI-M30 |

Theoretical Speed | Approx28,000 CPH | Approx24,000 CPH |

Insertion Direction | Standard360°,(0.1° Increment)inserted at any Angle | 4Directio0° /90° /180° /270°

(360°,0.1° increment Option) |

Component Span | 5mm~22mm | 5mm~22mm |

Größe der Karte | Min 50mm*50mm Max 400*300mm | Min 50mm*50mm Max 400*300mm |

Process Height | 900+20mm | 900+20mm |

Dicke der Platte | 0.79~2.36mm | 0.79~2.36mm |

Component Style | Capacitor,Transistor,Diode,Resistor,Inductance,Fuse Block,Other Axial style 52mm taped components | Capacitor,Transistor,Diode,Resistor,Inductance,Fuse Block,Other Axial style 52mm taped components |

Jumper | Independent Module: Dia 0.5-0.7mm

Tin Plated Copper Wire

2 kinds of jumper can insert at same time (Option) | Independent Module: Dia 0.5-0.7mm

Tin Plated Copper Wire

2 kinds of jumper can insert at same time (Option) |

Cut & Clinch Length | 1.2-2.2 mm (Adjustable ) | 1.2-2.2 mm (Adjustable) |

Clinch Angle | 10°-45° Internal Bending (Adjustable) | 10°-45° Internal Bending (Adjustable) |

Component Stations | 20 STD (Option 30,40,50,100) | 20 STD (Option 30,40,50,100) |

Machine Dimension | Main Body : L1950xW1650xH1700mm | Main Body: L1950xW1650xH1700mm |

Component Station Size | L2000xW1000xH1500 mm (20 stations) | L2000xW1000xH1500 mm (20 stations) |

Gewicht | Main Body: Approx 1200kg | Main Body: Approx 1200kg |

Leistungsbedarf | AC220V,Single Phase,50/60Hz,1.5Kw | AC220V,Single Phase,50/60Hz,1.5Kw |

Power Protection | UPS 15 minutes duration after power cut-off (Option) | UPS 15 minutes duration after power cut-off (Option) |

Luftdruck | 0.6 Mpa | 0.6 Mpa |

Luftverbrauch | 0.2 M³/min | 0.2 M³/min |

Environmental Temperature | 20°C ±10°C | 20°C ±10°C |

Noise Level | Approx75 dB(A) | Approx75 dB(A) |

Position Teaching | Vision System

Multi Fiducial (option) | Vision System

Multi Fiducial (option) |

Component Centering | STD Mechanical Centering | STD Mechanical Centering |

Axis Driving System | AC Servo Motor | AC Servo Motor |

Chain Driving | Dual Chain With Dual Servo Motor Drive | Dual Chain With Dual Servo Motor Drive |

Data Input Style | USB Port, Excel Format | USB Port, Excel Format |

Operation System | Chinese/English Interface (Windows®Platform) LCD Display 中英文界面,视窗平台,液晶显示 | Chinese/English Interface (Windows®Platform) LCD Display 中英文界面,视窗平台,液晶显示 |

Operation Mode | Auto / Semi Auto | Auto / Semi Auto |

Worktable Rotation | Clockwise / Counter Clockwise

Conveyor Track | Clockwise / Counter Clockwise

Conveyor Track |

Board Inload | Conveyor Inload Right To Left(Selectable) | Conveyor Inload Right To Left(Selectable) |

Programming] | On-line Teaching | On-line Teaching |

Futtermittel | Stepping Motor Control Feeding | Air Cylinder Control Feeding |

Mark Identification | Programming handle, touch screen operation in front and back | Touch screen operation in front and back |

Feet Material & Diameter | aluminum Foot diameter:0.6-0.8mm | aluminum ;Foot diameter:0.6-0.8mm |