NI-R20 | Super Series Radial Component Insert Machine

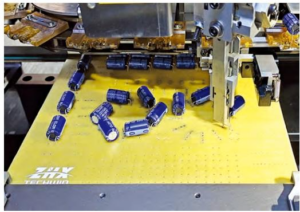

The NI-R20 Super Series Radial Component Insert Machine, belonging to the M, H, and K series of component insertion machines, is a key piece of equipment in the through-hole mounting process of electronic manufacturing. Its core positioning is to adapt to diverse, high-precision mass production needs, seamlessly connecting to surface mount technology (SMT) production lines and special processes. It is widely used in PCB insertion production for power supplies, small appliances, automotive electronics, industrial control boards, and other products, and is particularly adept at solving the balance between flexibility and stability in complex processes.

NI-R20 | Super Series Radial Component Insert Machine

- Popis

Popis

Intelligent Rail Transmission System More Efficient. The new intelligent rail transmission system is no longer a simple mechanical PCB stop device,but a program to transmit PCB in time according to the production status to reduce the waiting time. You can also choose an off-line programming system to reduce the line change time and improve the operation efficiency of the process.

High Adaptability Excellent Process Capability. The HR/MRseries insert system,which integrates highdensity operation and composite insert process technology. can significantly improve your process ability.The customizable multi span combination option, as well as the original 90bending and lying down element mechanism. combined with the technical innovation such as the detachable lower cutter base, improve the flexibility and adaptability of the insertion process to a new level.

Resistance Mechanical Stress Controllable More Stable. The new intelligent rail transmission system is no longer a simple mechanical PCB stop device,but a program to transmit PCB in time according to the production status to reduce the waiting time. You can also choose an off-line programming system to reduce the line change time and improve the operation efficiency of the process

specifikace

Položka | NI-H20 | NI-R20 | |

Theoretical Speed | Approx 28,000 CPH | Approx 20,000 CPH | |

Insertion Direction | 0��-360��, 1�� Increment | 0��-360��, 1�� Increment | |

Lead Span | 2.5mm/5.0mm;2.5mm/5.0mm/7.5mm; 5.0mm/7.5mm/10.0mm;2.5mm/3.5mm/5.0mm; 2.5mm/5.0mm/7.5mm/10.0mm; 10.0/12.5/15.0mm. Selectable | 2.5mm/5.0mm;2.5mm/5.0mm/7.5mm; 5.0mm/7.5mm/10.0mm;2.5mm/5.0mm/7.5mm/10.0mm; 10.0/12.5/15.0mm. Selectable | |

Velikost desky | Min 50mm*50mm Max 400mm*350mm | Min 50mm*50mm Max 400mm*350mm | |

Process Height | 900+20mm | 900+20mm | |

Tloušťka desky | 0.79~2.36mm | 0.79~2.36mm | |

Component parameter | Max 23mm(26mm option);13mm;Height max 23mm (26mm option); Diameter within 13mm | Max 23mm(26mm);13mm;Height max 23mm (26mm option); Diameter within 13mm | Ԫ�����Max 23mm(��ѡ26mm);Ԫ��ֱ��13mm֮��;Height max 23mm (26mm option); Diameter within 13mm

����,�����,������,LED ��,��������,����,������,��Ȧ,��λ��,����˿��,�۶�˿����ʽƫ����װ��

Capacitor, Transistor, Triode, LED Mini Switch, Resi

stor, Connector, Coil, Potentiometer, Fuse Block, Other

Radial style taped components. |

Component Style | Capacitor, Transistor, Triode, LED, Mini Switch, Resistor, Connector, Coil, Potentiometer, Fuse Block, Other

Radial style taped components | Capacitor, Transistor, Triode, LED, Mini Switch, Resistor, Connector, Coil, Potentiometer, Fuse Block, Other

Radial style taped components | |

Cut & Clinch Length | 1.2/1.5/1.8mm (Selectable ) | 1.2/1.5/1.8mm (Selectable ) | |

Clinch Angle | 25��~45�� External Bending ; 3.5mm Lead Span Internal/External Bending Selectable 3.5mm / | 25��~45�� External Bending ; 3.5mm Lead Span Internal/External Bending Selectable 3.5mm / | |

Component Stations | 20 STD ( 10,30,40,60,80,100 Option ) | 20 STD ( 30,40,60,80,100 Option ) | |

Machine Dimension | Main Body : L1950xW1650xH1700mm | Main Body : L1950xW1650xH1700mm | |

Component Station Size | L1800xW1450xH1100 mm | L1800xW1450xH1100 mm | |

Hmotnost | Main Body ; Approx 1200kg | Main Body ; Approx 1200kg | |

Požadavek na napájení | AC220V, Single Phase, 50/60Hz, 1.5Kw | AC220V, Single Phase, 50/60Hz, 1.5Kw | |

Power Protection | UPS ()15 minutes duration after power cut-off ( Option ) | UPS ()15 minutes duration after power cut-off ( Option ) | |

Tlak vzduchu | 0.6 Mpa | 0.6 Mpa | |

Spotřeba vzduchu | 0.3 M3/min | 0.3 M3/min | |

Environmental Temperature | 20�� �� 10�� | 20�� �� 10�� | |

Noise Level | Approx75 dB(A) | Approx75 dB(A) | |

Clinch Module Movement | AC Servo Motor ( Up, Down ) | Air Cylinder ( Up, Down ) | |

Tape Cutter | Single Stroke Cutting Feature , | Single Stroke Cutting Feature , | |

Station Feeding System | High Speed Valve | STD Valve | |

Component Transfer Assemble CTA | AC Servo Motor | Pneumatic Cylinder | |

Position Teaching | Systém Vision | Systém Vision | |

Multi Fiducial ( option ) | Multi Fiducial ( option ) | ||

Axis Driving System | AC Servo Motor | AC Servo Motor | |

Data Input Style | USB Port (Excel Format) | USB Port (Excel Format) | |

Operation System | Chinese/English Interface (Windows? Platform) LCD Display | Chinese/English Interface (Windows? Platform) LCD Display | |

Operation Mode | Auto / Semi Auto | Auto / Semi Auto | |

Component Density | High Density Insertion Style | High Density Insertion Style | |

Worktable Rotation | Conveyor Track | Conveyor Track | |

Board Inload | Conveyor Inload Left to Right(Selectable) | Conveyor Inload Left to Right(Selectable) | |

Programování | On-line Teaching | On-line Teaching | |

Loader/Unloader | Možnost | Možnost |